Espresso machine with dosing mechanism

A technology of coffee machines and mechanical valves, which can be used in home appliances, kitchen appliances, beverage preparation devices, etc., and can solve problems such as unreliability, complicated structure, and expensive manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

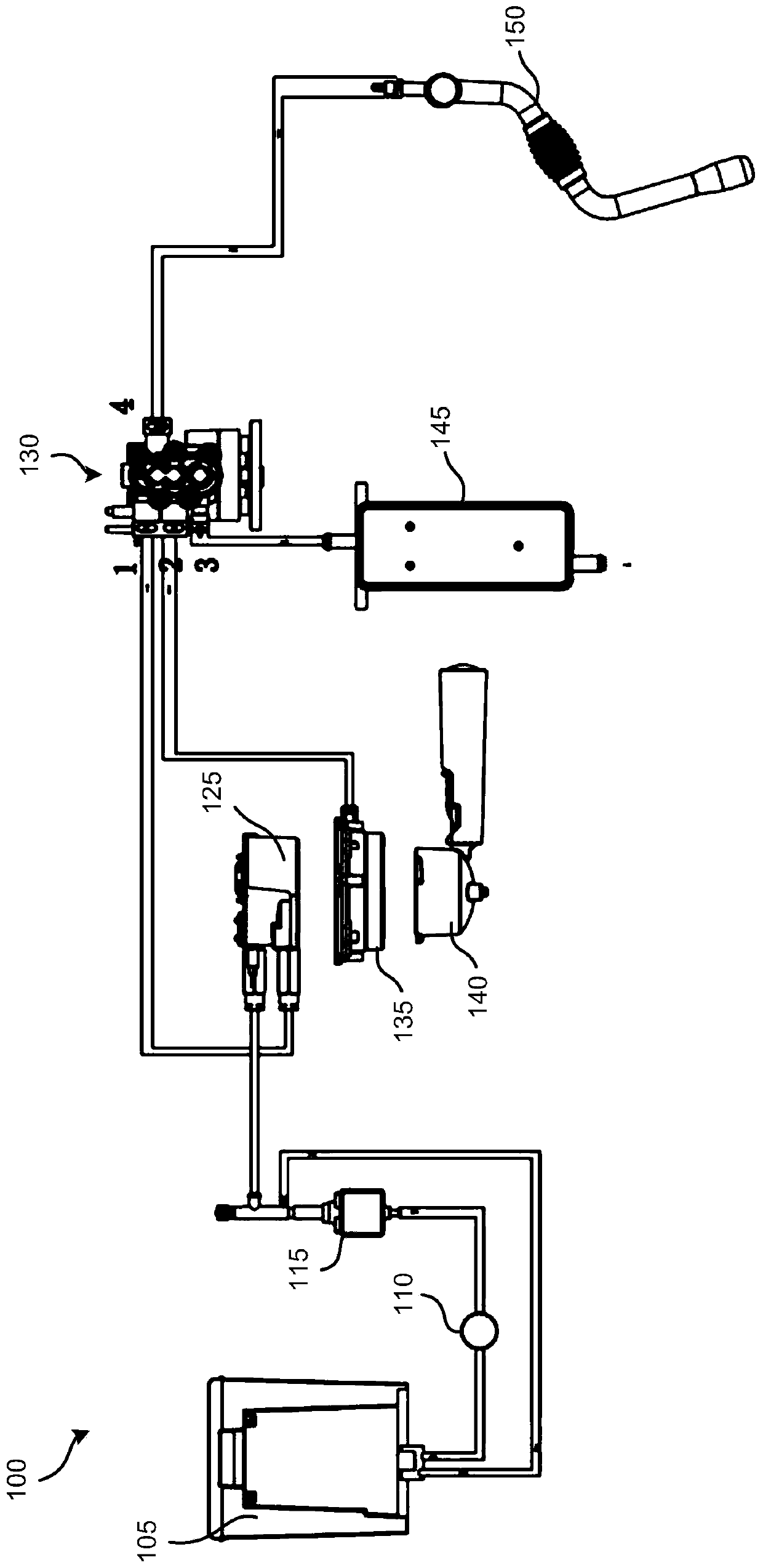

[0044] figure 1 is a general flow diagram of the components within the espresso machine 100 according to an example embodiment. The espresso machine 100 includes a water reservoir 105 . In one embodiment, the water reservoir 105 is in fluid communication with the flow meter 110 . Water may flow from flow meter 110 to pump 115 . In some embodiments, pump 115 may include a return line 120 to allow water to circulate back to reservoir 105 as needed.

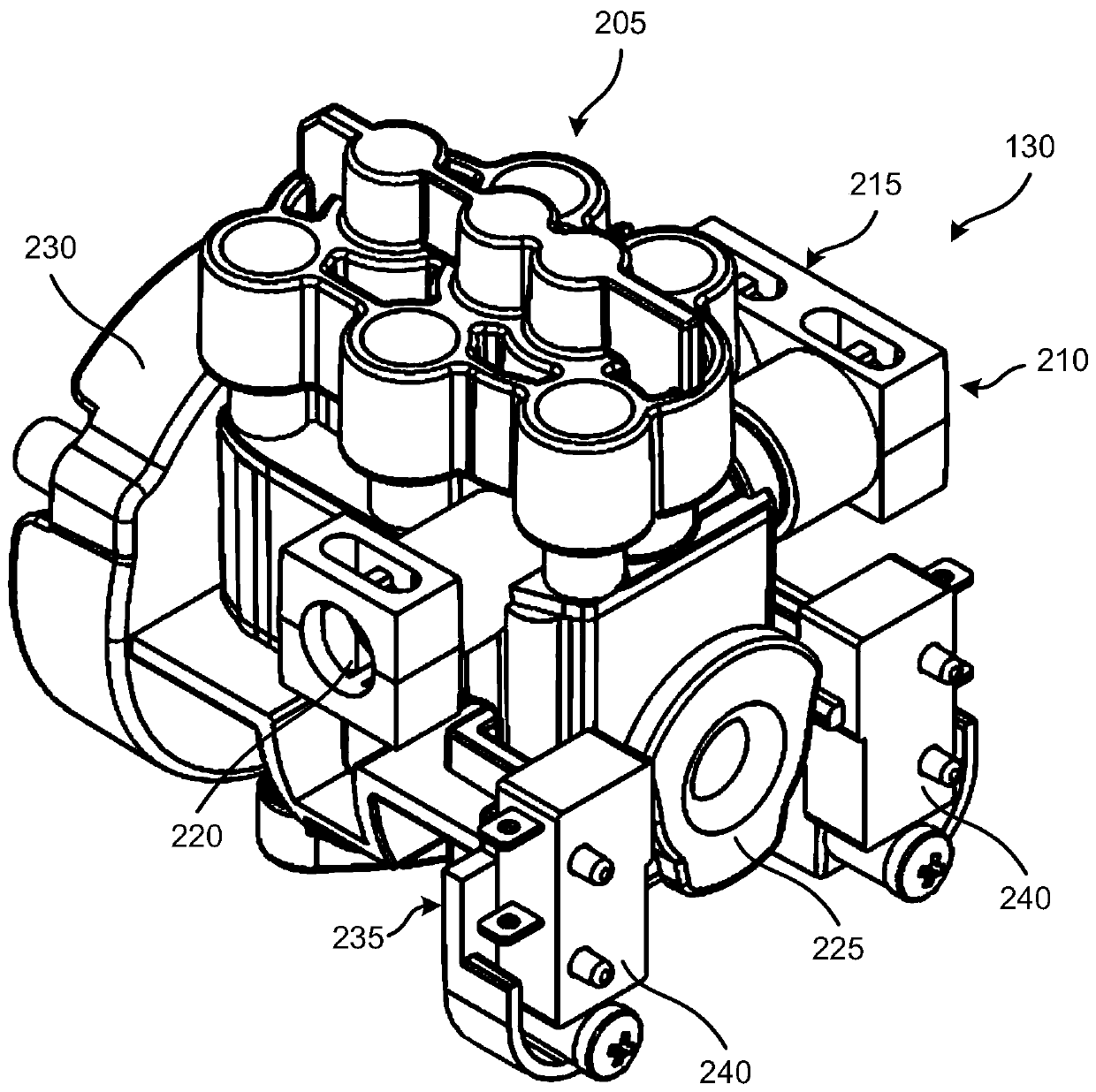

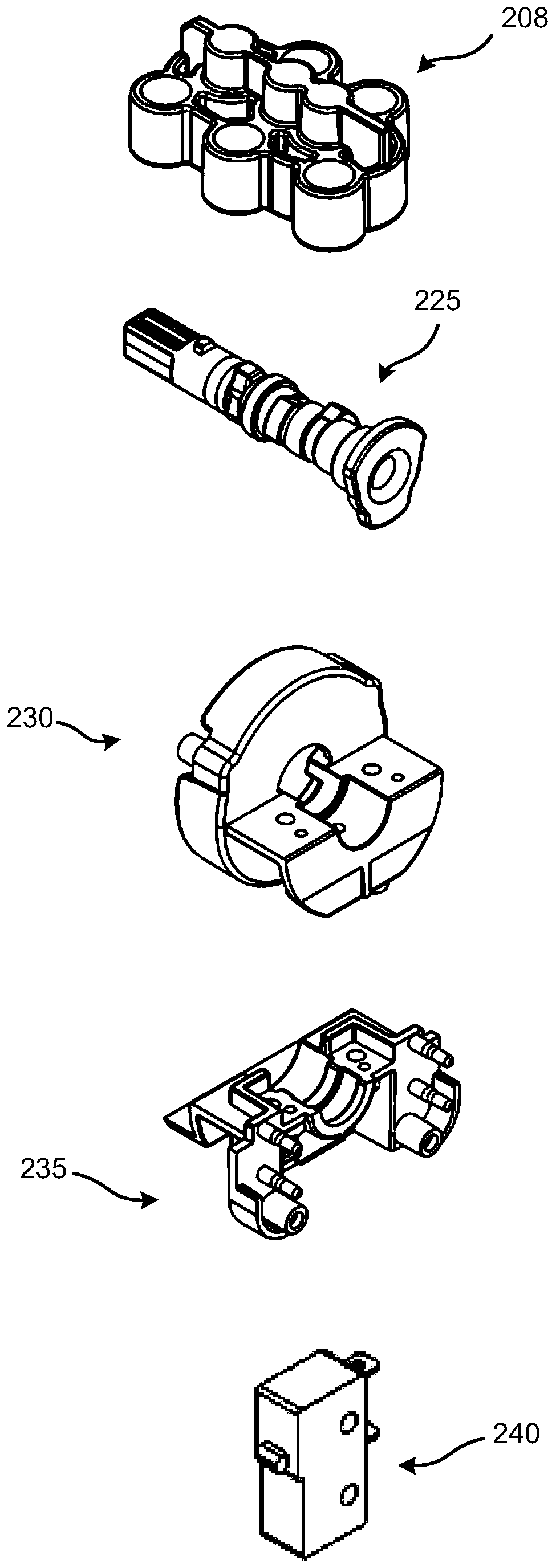

[0045] Water may be pumped from pump 115 to the input of water heater 125, which in this embodiment is a heating block in which the water is heated to the desired temperature. The heated water may then flow from the output of the heating block 125 to the valve mechanism 130 . In an example embodiment, valve mechanism 130 may output water to one or more different destinations. For example, valve mechanism 130 may direct water to a first destination, namely, a brew head (in one embodiment including funnel holder 135 and funnel ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com