Heat radiator of light emitting diode (LED) lamp

A technology of LED lamps and radiators, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc., can solve the general heat dissipation effect of dense fins, increase material and production costs, and solve the Easily damaged and other problems, to achieve the effect of improving the performance of lamps, light weight and sufficient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

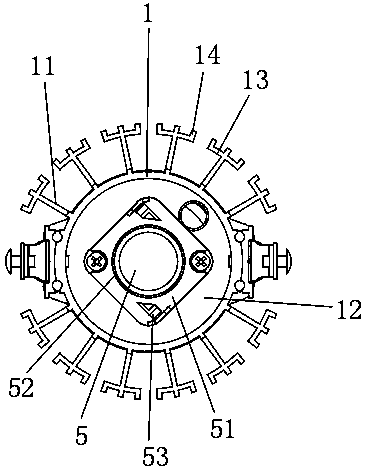

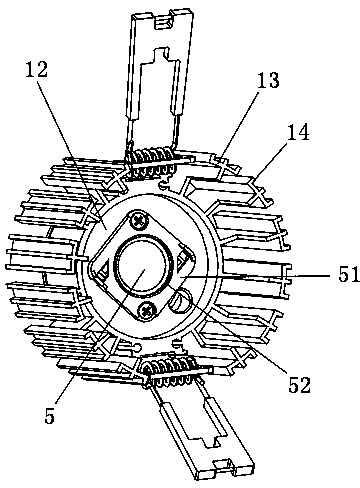

[0038] A heat sink for LED lamps, comprising a cylinder body 1, a main heat sink 11 arranged radially on the outer surface of the cylinder body 1, and a heat conduction plate 12 disposed inside the cylinder body 1, on which a light-emitting chip of an LED lamp is disposed on the heat conduction plate 12 , the outer end of the main heat sink 11 is perpendicular to the main heat sink 11 and is provided with a secondary heat sink 13 , and the outer surface of the secondary heat sink 13 is provided with a plurality of heat dissipation teeth 14 . The light-emitting chip includes a core board and a light-emitting surface 5 arranged on the core board. The light-emitting chip is covered with a calender 51, and the center of the calender 51 is provided with a through hole corresponding to the position of the light-emitting surface 5. The wall of the through hole protrudes forward to form a limiting ring 52 . When combined with other components of the lamp, the rear end of the reflector...

Embodiment 2

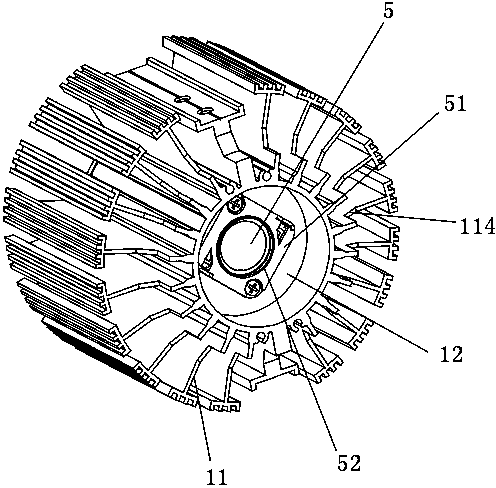

[0043] The difference from the above embodiment is that the heat dissipation teeth 14 are four evenly distributed on the arc-shaped plate, and the heat dissipation teeth 14 on both sides are flush with the two sides of the arc-shaped plate. The inner side of the main heat dissipation fin 11 extends forward to form an extended heat dissipation section. An inclined connection portion 114 is provided between the outer side of the extended heat dissipation section and the main heat dissipation fin 11 . A pier 113 is provided at the joint between the main heat sink 11 and the cylinder body 1 , and the thickness of the pier 113 is greater than that of the main heat sink 11 .

Embodiment 3

[0045] The difference from the above embodiments is that the outer side of the main heat sink 11 and the auxiliary heat sink 13 extend forward to form an extended heat dissipation section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com