Triangular chained clamping and cutting system for small garlic harvester

A harvester and triangular technology, which is applied in the field of the triangular-type chain clamping and cutting seedling system of a small garlic harvester, can solve the problems of easy wear and tear of the seedling cutting knife, unreasonable setting of the clamping mechanism, and affecting the transmission of the seedlings when the harvester moves. , to facilitate post-processing, improve cutting efficiency, and improve transmission strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

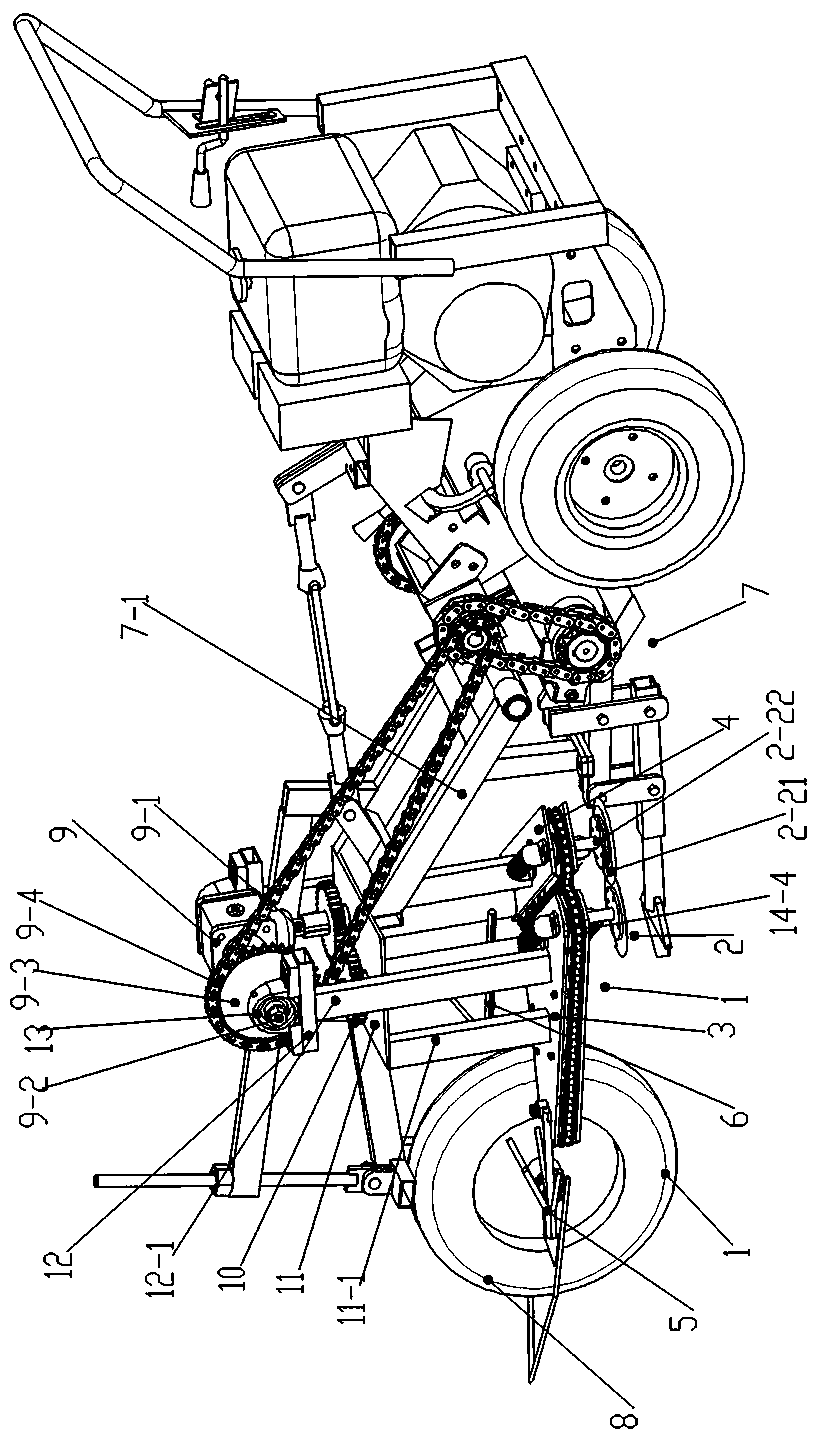

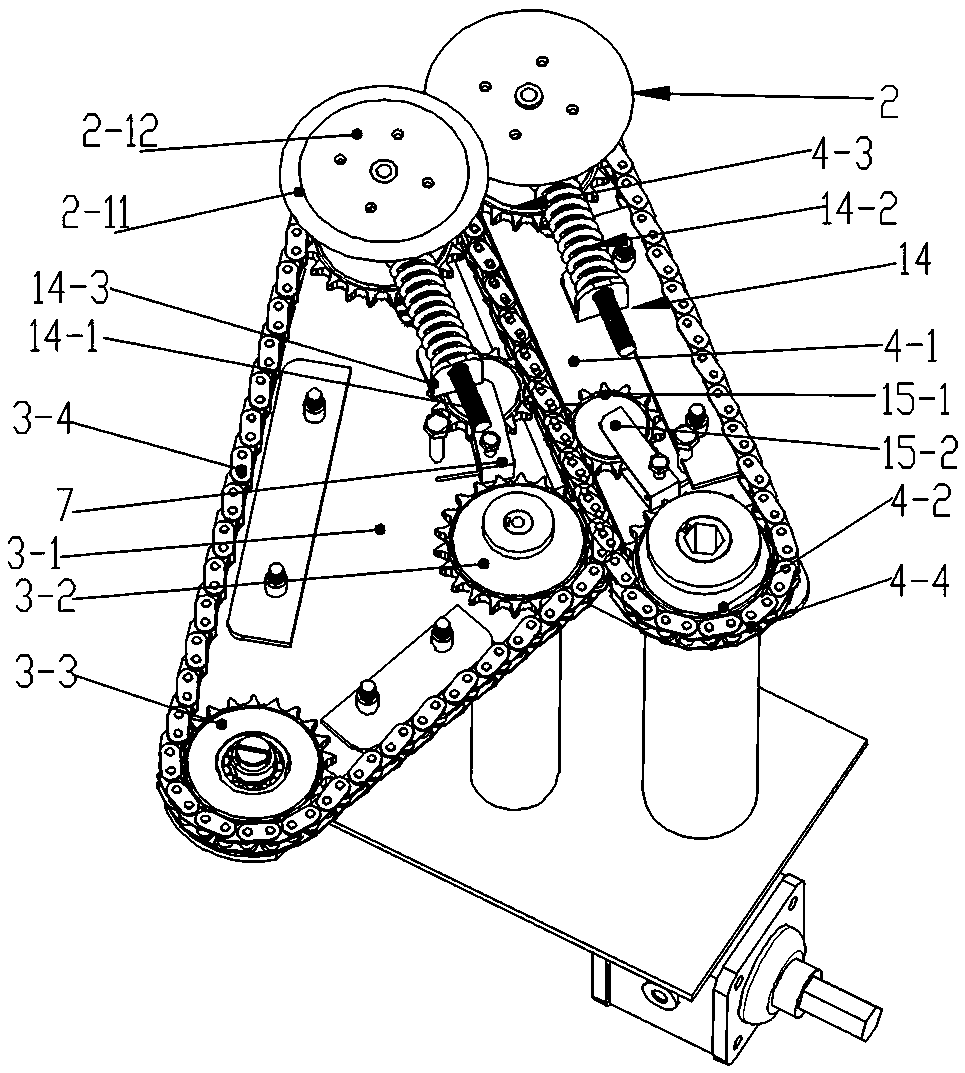

[0014] Such as figure 1 , figure 2 As shown, a small garlic harvester triangular chain clamping and cutting system includes a clamping arm 1, a seedling cutting device 2, a grain lifter 5 and a guide 6; the clamping arm 1 consists of an isosceles triangle The transmission mechanism 3 is composed of a rectangular transmission mechanism 4, and a clamping channel is formed between the two clamping arms; the isosceles triangle transmission mechanism 3 includes a clamping triangular substrate 3-1, which clamps the top of the triangular substrate 3-1. The angle rotation is installed to clamp the driving gear 3-2, and the two bottom angle rotations are installed to clamp the driven gear 3-3; the clamping drive gear 3-2 and the two clamping driven gears 3-3 pass through the chain 3- 4 transmission connection to form a triangular transmission belt; the rectangular transmission mechanism 4 includes a clamping long substrate 4-1, one end of the clamping long substrate 4-1 rotates and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com