Display system for planar design

A graphic design and display system technology, applied in applications, home appliances, display stands, etc., can solve problems such as poor layering and dynamic effects, difficulty in arousing the interest of viewers, and rigid display methods, achieving strong practicability and a sense of hierarchy. and dynamic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

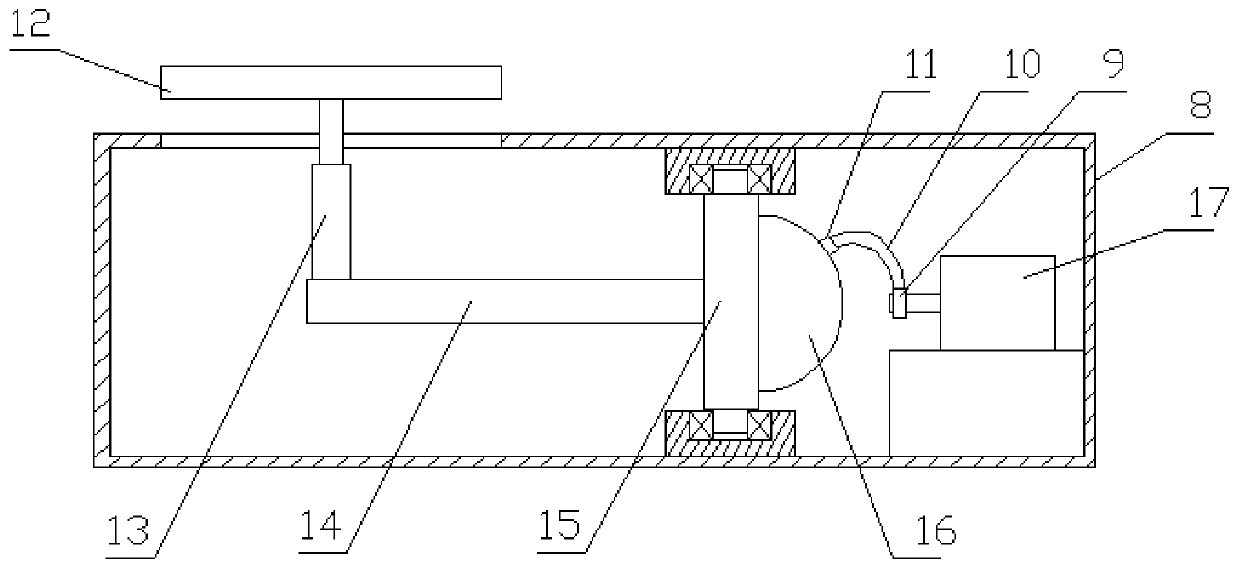

[0020] like figure 1 As shown, a display system for graphic design provided by the present invention includes a box body 8 used as a support, and a plurality of motors 17 used as a driving power source are arranged inside the box body 8, and the output of the motors 17 A cylindrical body 9 is fitted on the shaft, and the cylindrical body 9 is fixedly connected with the output shaft of the motor 17 .

[0021] The outer wall of cylinder body 9 is fixedly connected with one end of curved rod 10, and the other end of described curved rod 10 is fixed with slider 11; The side of described slider 11 is provided with vertically placed rotating shaft 15, and described rotating shaft 15 passes The bearing is mounted on the inner wall of the box body 8 , and a cam 16 is provided on the circumference of the rotating shaft 15 .

[0022] like Figure 5 and Image 6 As shown, the cam 16 includes a semicircular plate body 1601, the circumferential plane end of the semicircular plate body 1...

Embodiment 2

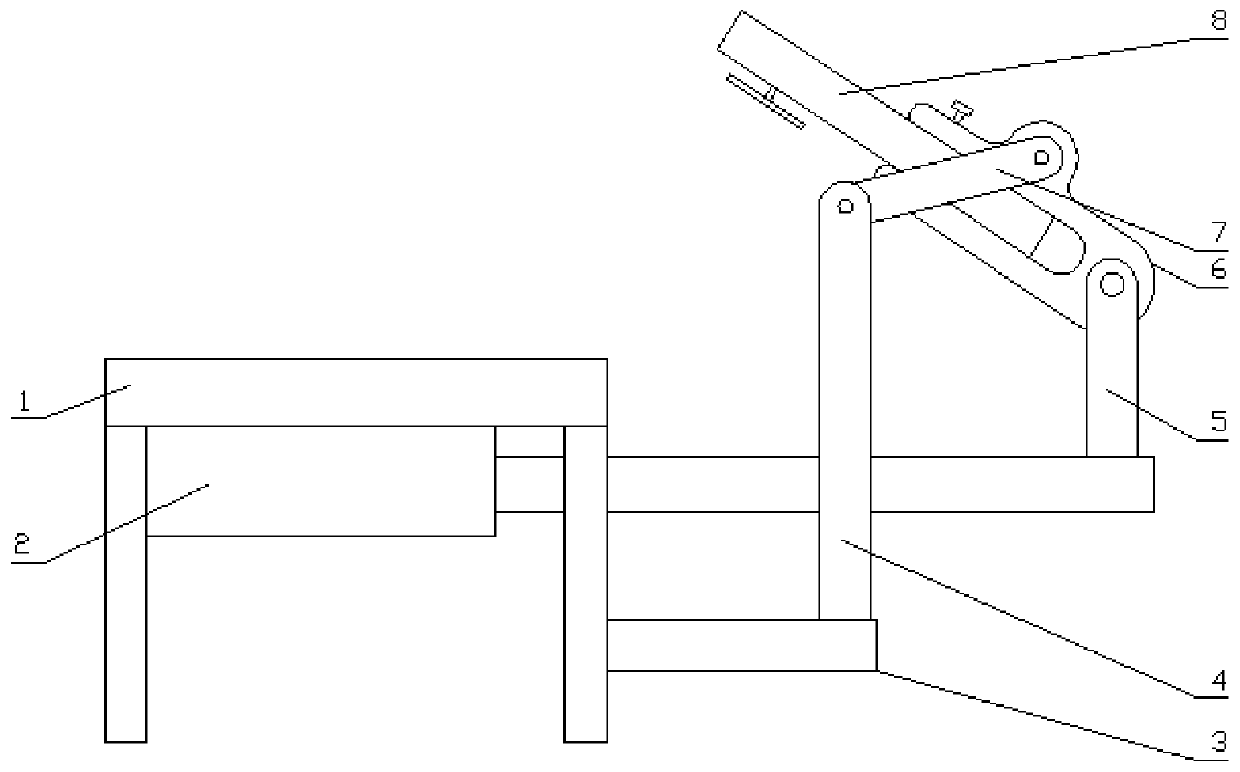

[0028] As a further improvement on the basis of Example 1, such as figure 2 As shown, the two sides of the box body 8 are symmetrically provided with clamping and clamping structures 6 for clamping the box body 8 .

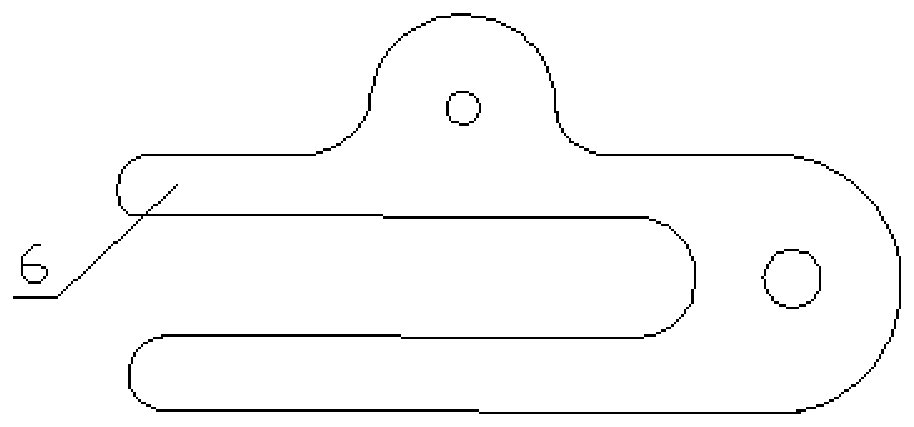

[0029] like image 3 and Figure 4 As shown, the snap-in clamping structure 6 includes plate body one, plate body two and plate body three which are sequentially fixedly connected to form a U-shaped opening snap-in structure, and the middle section of the plate body one is fixed with connecting lugs, so The first board is provided with at least one fastening device 1 for fixing the position of the box body 8 , and the third board is provided with at least one fastening device 2 for fixing the position of the clamping structure 6 .

[0030] The above clamping structure 6 is used for clamping the box body 8, and it is convenient to fix the position of the box body 8 on the wall or other exhibition stands for exhibition.

Embodiment 3

[0032] As a further improvement on the basis of Example 2, such as figure 2 As shown, the plate body 2 is hinged with one end of the pole 2 5, and the other end of the pole 2 5 is vertically fixed at the end of the piston rod of the hydraulic cylinder 2, and the hydraulic cylinder 2 is fixed under the table top of the table body 1. . The table legs of the table body 1 are also fixed with a horizontally placed pole three 3, and the end of the pole three 3 away from the table body 1 is vertically fixed with pole four 4, and the pole four 4 deviates from the pole three. The end of 3 is hinged with one end of connecting rod 7, and the other end of said connecting rod 7 is hinged with lug.

[0033] When the length of the piston rod of the hydraulic cylinder 2 changes, the surface inclination angle of the box body 8 can be changed around the hinged end of the lug and the connecting rod 7, and the inclination angle change of the visible surface of the box body 8 can be realized to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com