A compound vitamin processing device

A multivitamin and processing device technology, applied in solid separation, chemical instruments and methods, grain processing, etc., can solve the problem of no automatic separation and cutting, and achieve the effect of flexible use, efficient operation and adjustment of operation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

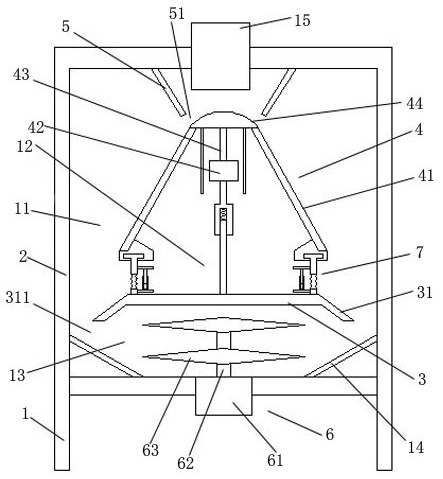

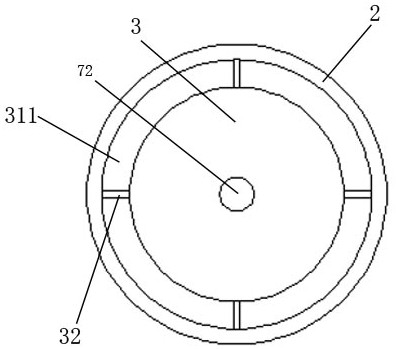

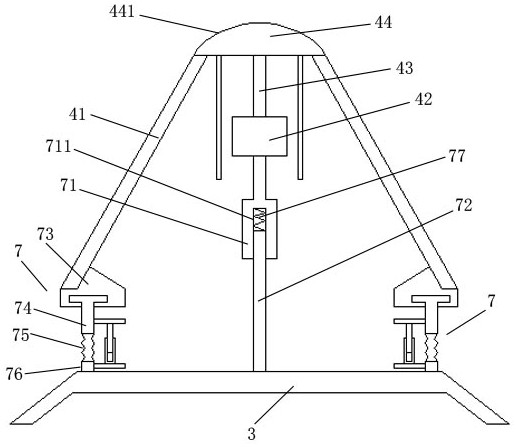

[0023] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0024] Such as Figures 1 to 4 As shown, a compound vitamin processing device includes a bracket 1, a processing tank body 2, a feeding ring 5, an upper sieving mechanism 4, a closing plate 3, and a lower stirring mechanism 6; the two sides of the bottom of the processing tank body 2 Mounting bracket 1; the middle of the upper end of the processing tank 2 is provided with a feeding pipe 15; the upper end of the processing tank 2 is provided with a feeding ring 5; the lower end of the feeding ring 5 is located around the feeding The lower end of the tube 15 is below the outside around the periphery; the periphery of the closure plate 3 is horizontally fixed below the inside of the processing tank body 2 through a plurality of connecting rods 32; the closure plate 3 divides the interior of the processing tank body 2 into an upper part The separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com