Guide-adjustable bending machine for automobile square pipe fitting

A square tube, adjustable technology, applied in the field of bending machines, can solve the problems that the top surface of the tube cannot be pressed, affect the quality of the bent tube, shake and other problems, achieve reasonable and accurate mechanical action coordination, sophisticated device structure design, and improved performance. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below according to the drawings and embodiments.

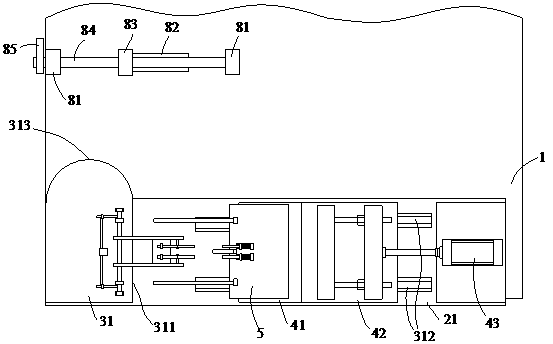

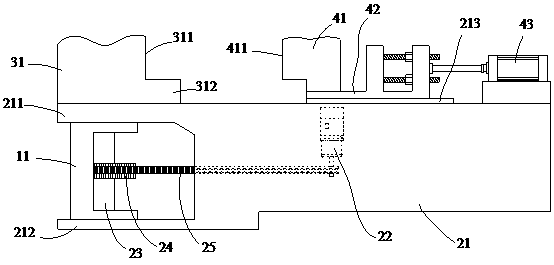

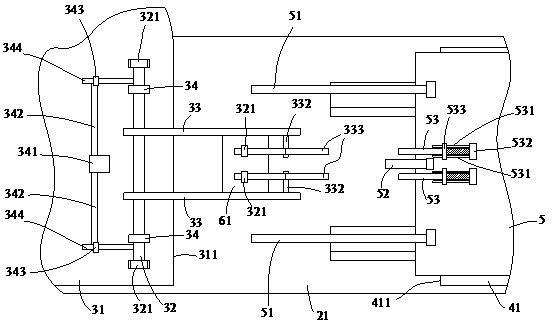

[0038] refer to Figure 1-Figure 7 According to the present invention, the bending machine for guiding adjustable automobile square pipes includes a frame 1, a rotating mechanism, a left mold mechanism, a right mold mechanism, and a guide roller mechanism.

[0039] Frame 1 is a fixedly installed part of each mechanism. According to the traveling direction of the pipe to be bent, the front end of the frame 1 is respectively equipped with a left mold mechanism and a right mold mechanism. It is placed behind the left mold mechanism and the right mold mechanism.

[0040] The rotating mechanism includes a rotating frame 21, a rotating motor 22, a rotating shaft 23, a rotating gear 24, and a rotating chain 25. The front end of the frame 1 is provided with a cylindrical casing 11 on the left side, the cylindrical casing 11 is vertically arranged, and its side has an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com