A steel bar bending device for building construction

A technology for building construction and bending devices, applied in cleaning methods and appliances, cleaning methods using gas flow, chemical instruments and methods, etc., can solve problems such as low bending efficiency, achieve improved bending efficiency, convenient adjustment, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

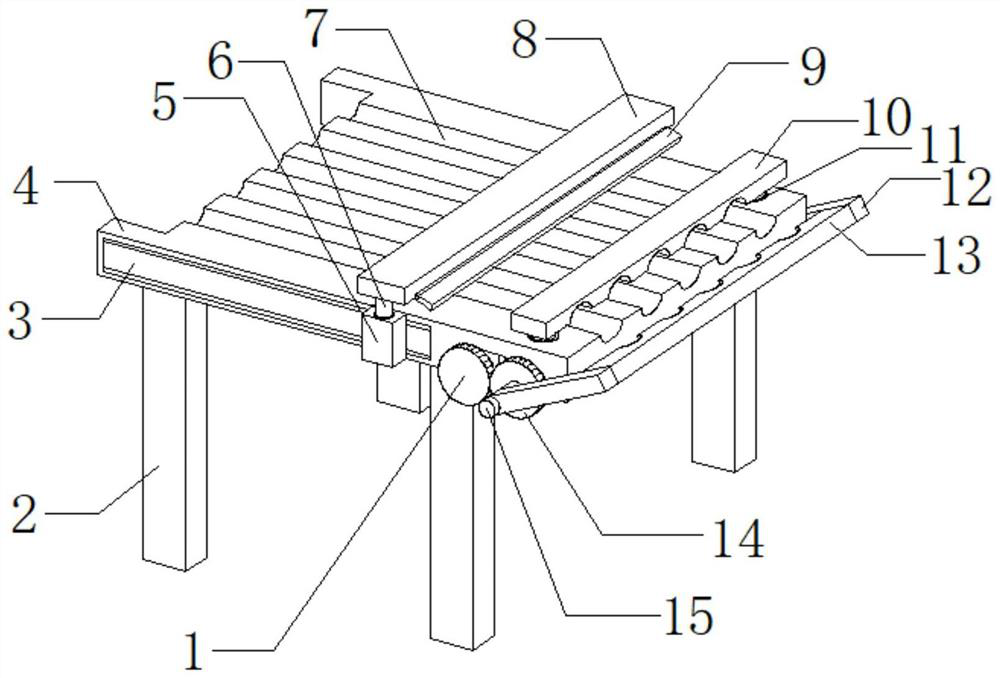

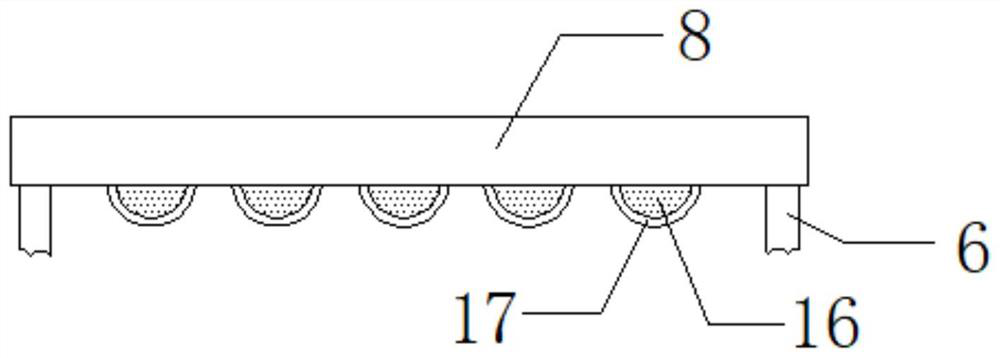

[0028] refer to Figure 1-3 , a steel bar bending device for building construction, comprising a support platform body 4 and four support legs 2, the four support legs 2 are respectively installed on the bottom four-corner outer walls of the support platform body 4 by bolts, and the top outer wall of the support platform body 4 is opened There are placement grooves 7 arranged horizontally at equidistant distances, and the outer walls at both ends of one side of the support platform body 4 are connected with rotating rods 15 through bearings, and the outer walls at the adjacent ends of the circumferences of the two rotating rods 15 are sleeved with second gears 14 The outer walls of the two rotating rods 15 that are far away from each other are connected with a splint 12 by bolts, and the top outer walls of the adjacent ends of the two splints 12 are connected with the same second pressure plate 13 by bolts, and the bottom outer wall of the second pressure plate 13 is provided w...

Embodiment 2

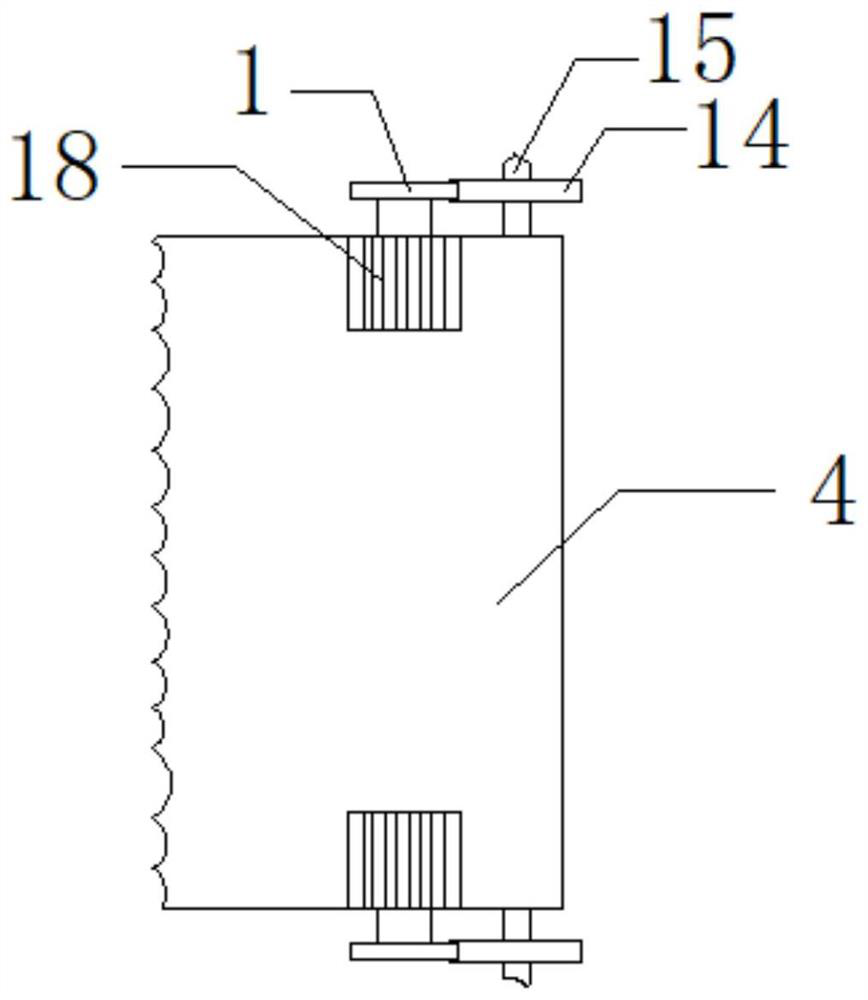

[0033] refer to Figure 1-5 , a steel bar bending device for building construction, also includes an installation groove opened on the outer wall of the other side of the support platform body 4, and the bottom inner wall of the installation groove is provided with a fourth support plate 22, and the other side of one end of the support platform body 4 The outer wall is connected with the second rotating motor 21 by bolts, and the output shaft of the second rotating motor 21 is connected with the outer wall of one end of the fourth support plate 22 by bolts, and the outer wall of one side of the fourth support plate 22 is provided with an installation port, and the installation port The inner wall of the air duct 25 is connected with an air duct 25 by bolts, and one side of the air duct 25 inwall is connected with a filter screen 23 by bolts, and the outer wall of the air duct 25 top other side is connected with a blower 24 by bolts.

[0034] After the device is used, the fourt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com