Protective structure for steel ladle slide water hole and using method of protective structure

A technology of sliding nozzle and protective structure, which is applied in casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems of oxidative decarburization, cracks, etc., and achieve the effect of reducing oxygen and nitrogen increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

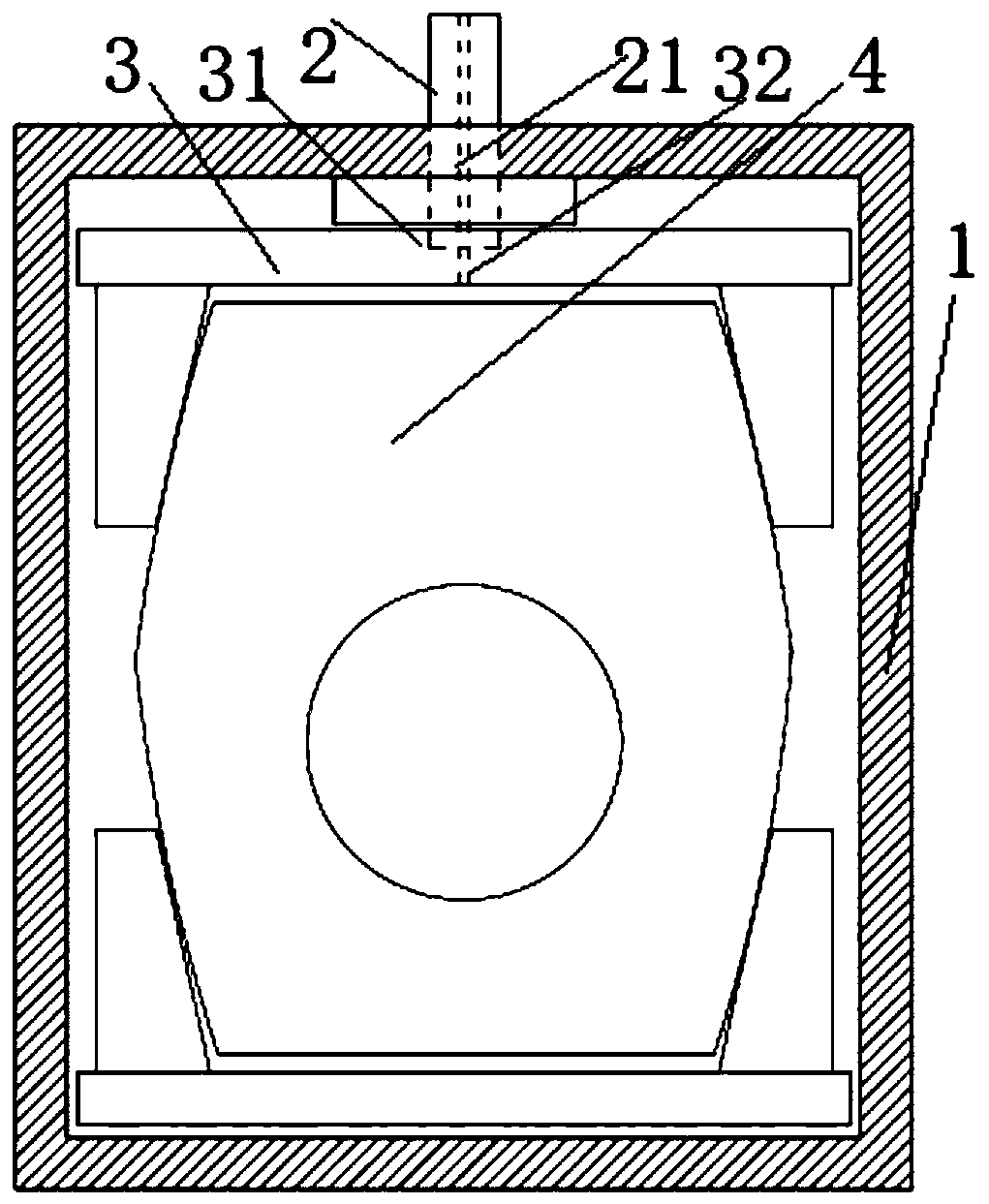

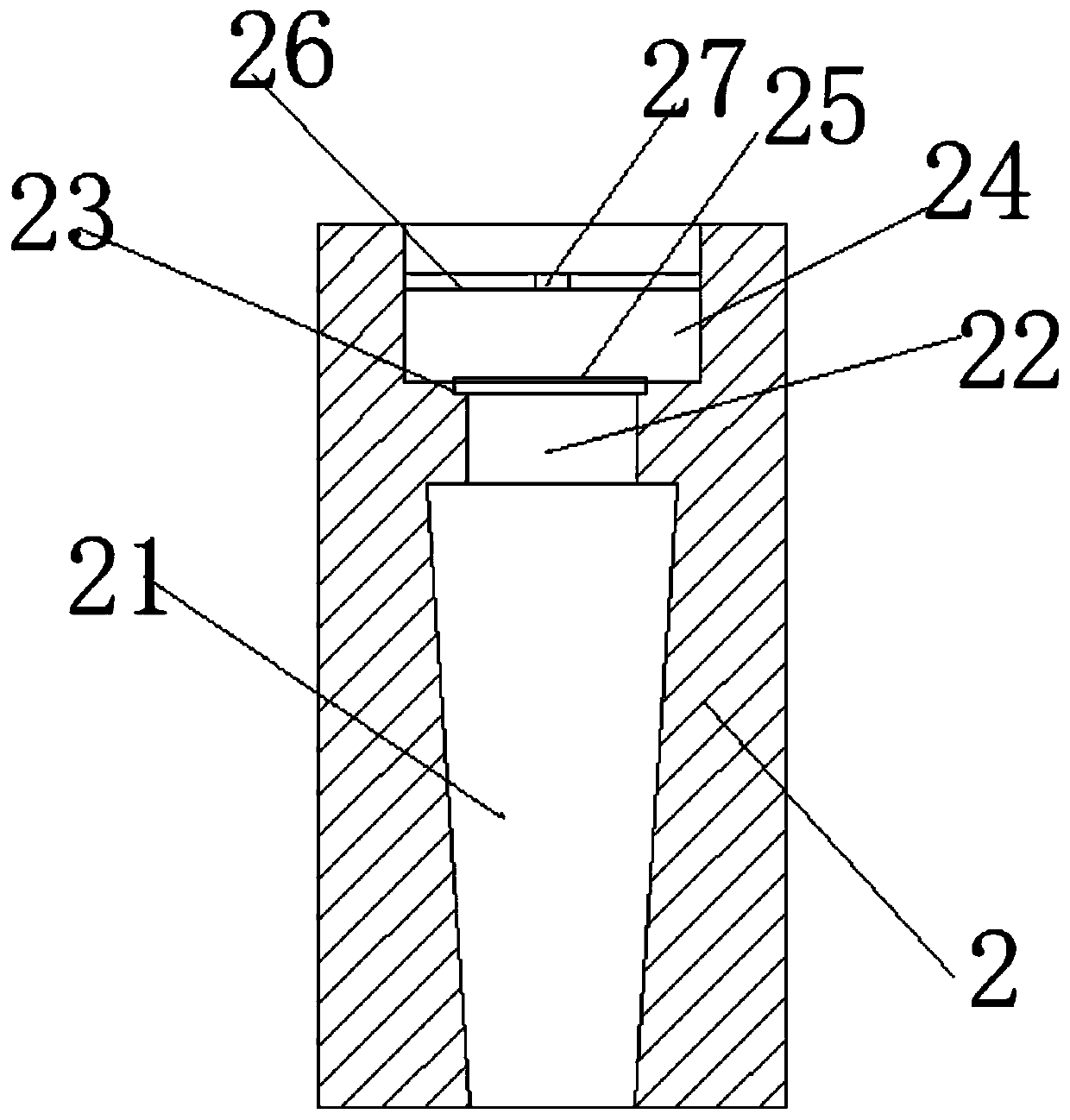

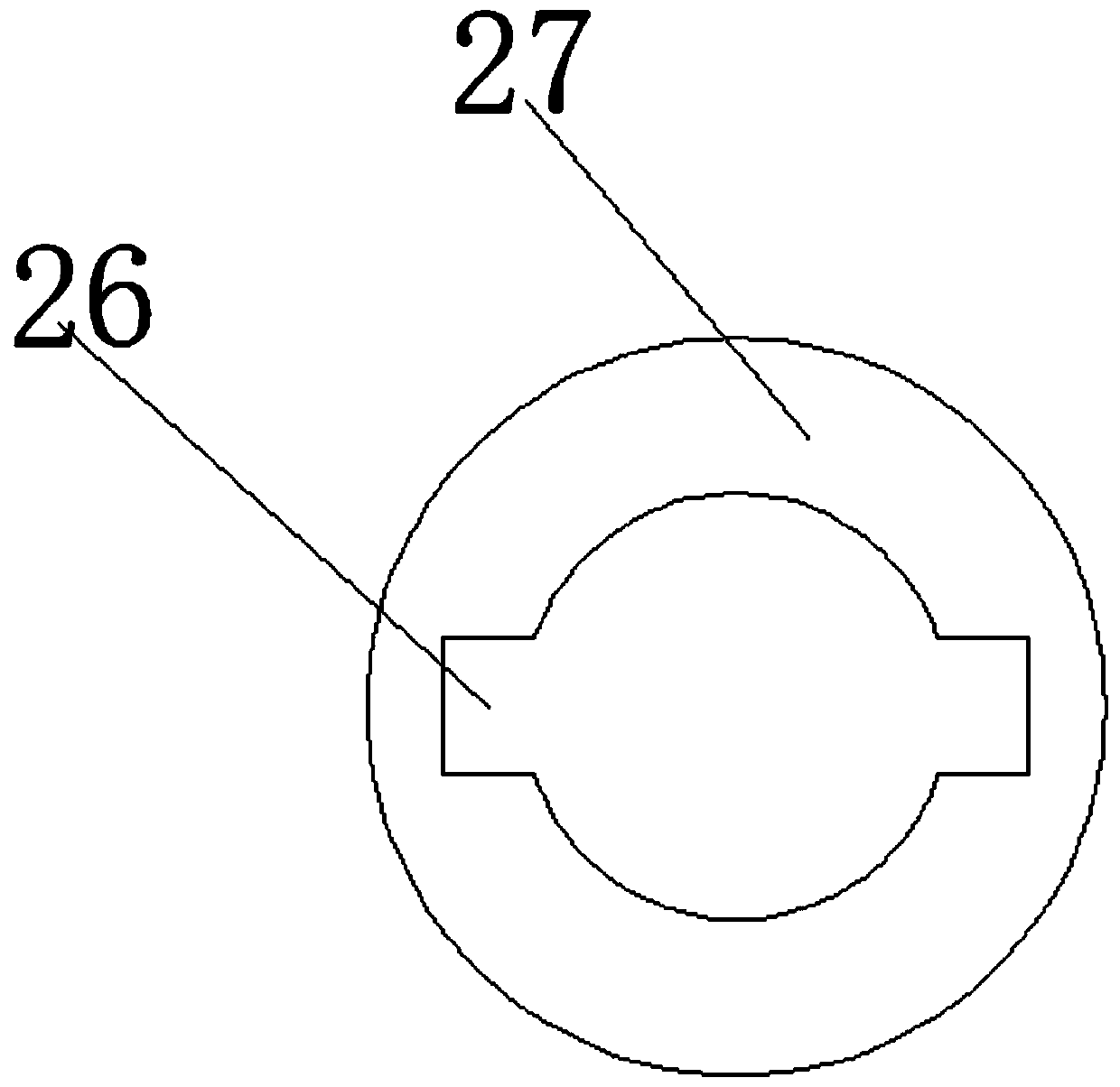

[0034] A protective structure for a ladle sliding nozzle, the sliding nozzle 4 is arranged in the sliding mold frame 1; the sliding nozzle 4 is connected with the sliding mold frame 1 through an adjusting mechanism; the adjusting mechanism includes an adjusting bolt, and the adjusting bolt It includes an adjusting bolt body 2; the adjusting bolt body 2 is provided with an air supply channel 21 along the axial direction, and the air supply channel 21 is set through the adjusting bolt body 2; one end of the adjusting bolt is arranged on the outside of the sliding mold frame 1, and the other One end extends to the inside of the sliding mold frame 1; the adjusting bolt is connected with an argon gas supply part; when in use, the argon gas supply part is the adjusting bolt for gas supply operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com