A grabbing device and press-fitting equipment using it

A grasping device and equipment technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of easy wear, inaccurate positioning, and many forehearths of non-metal material channels, and achieve good grasping stability. , The overall structure is compact and the conveying process is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

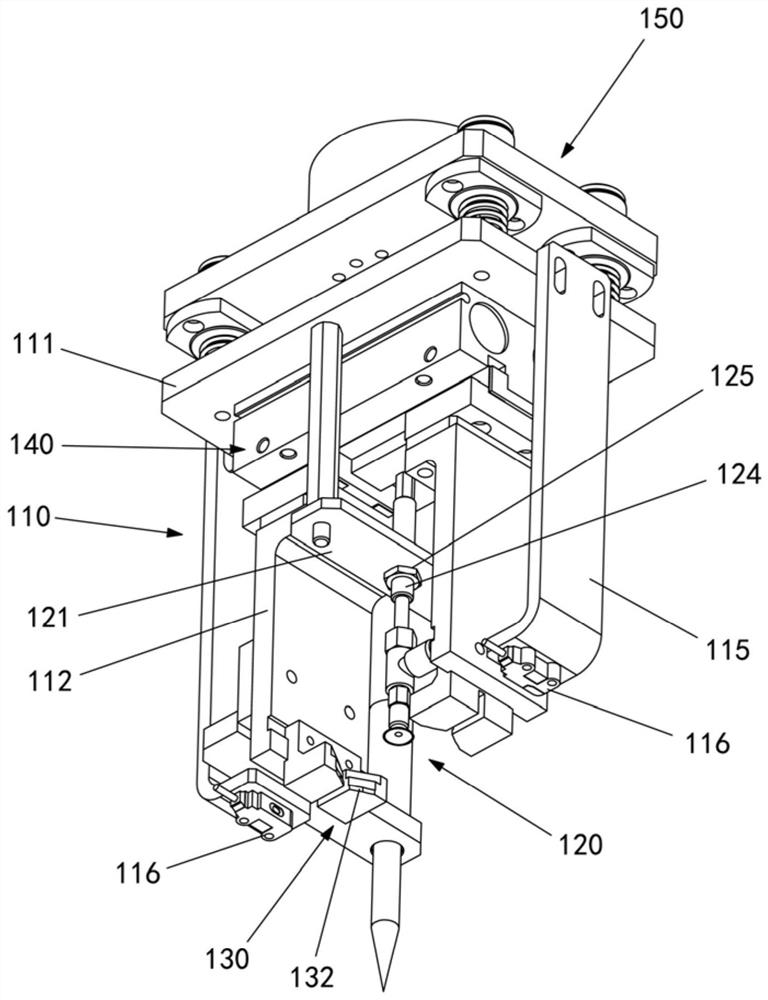

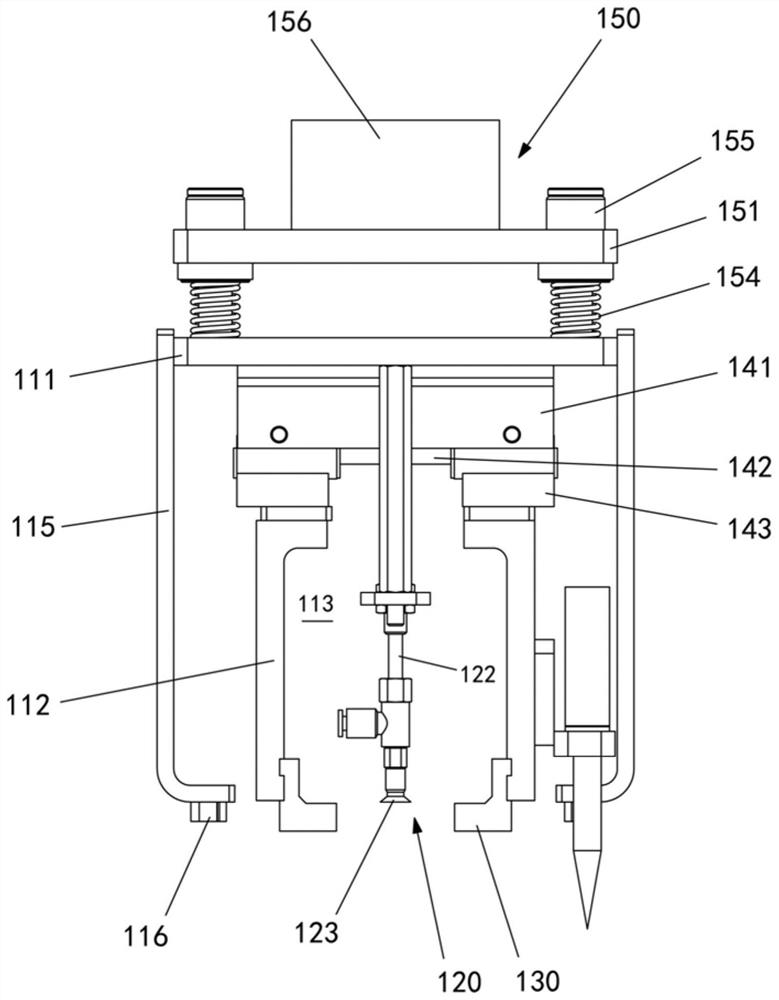

[0075] Such as figure 1 As shown in -4, a grabbing device 100 is used for grabbing engine cylinder block covers (bowl plugs, screw plugs) on the engine production line, including a clamping mechanism 110, a pressure absorber 120, two engaging part 130, the pressing mechanism 140 and the floating balance mechanism 150.

[0076] The clamping mechanism 110 includes a frame plate 111, two clamping arms 112, and the two clamping arms 112 are mounted on the frame plate 111 in a sliding manner, wherein the two clamping arms 112 can produce opposite or back-to-back lateral displacements , A containing structure 113 is formed between the two clamping arms 112 and the frame plate 111, and the pressure absorber 120 is located in the containing structure 113, so as to suck the blocking cap directly from above the blocking cap.

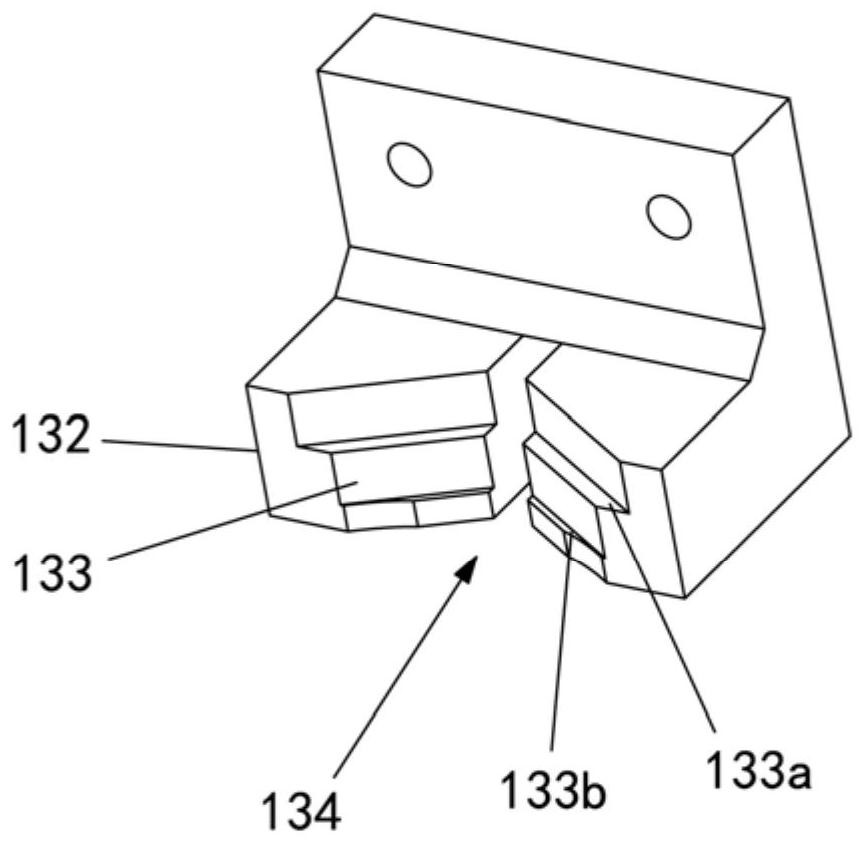

[0077] The two engaging parts 130 are provided on the two clamping arms 112 of the clamping mechanism 110 , and as the two clamping arms 112 move toward or away ...

Embodiment 2

[0095] Such as figure 1 As shown in -6, a press-fitting device is used to press-fit the bowl plug onto the engine block, including a material conveying device, a grabbing device 100 , a manipulator device 200 and a vertical punching device 300 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com