Stereoscopic horizontal storage rack for electrical steel raw coils for iron cores

An electrical steel and shelf technology, applied in display shelves, applications, display hangers, etc., can solve the problems that the storage capacity cannot meet the production needs of enterprises, unfavorable rational use of land for enterprises, and high space occupancy, and improve space utilization and structure. Compact, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

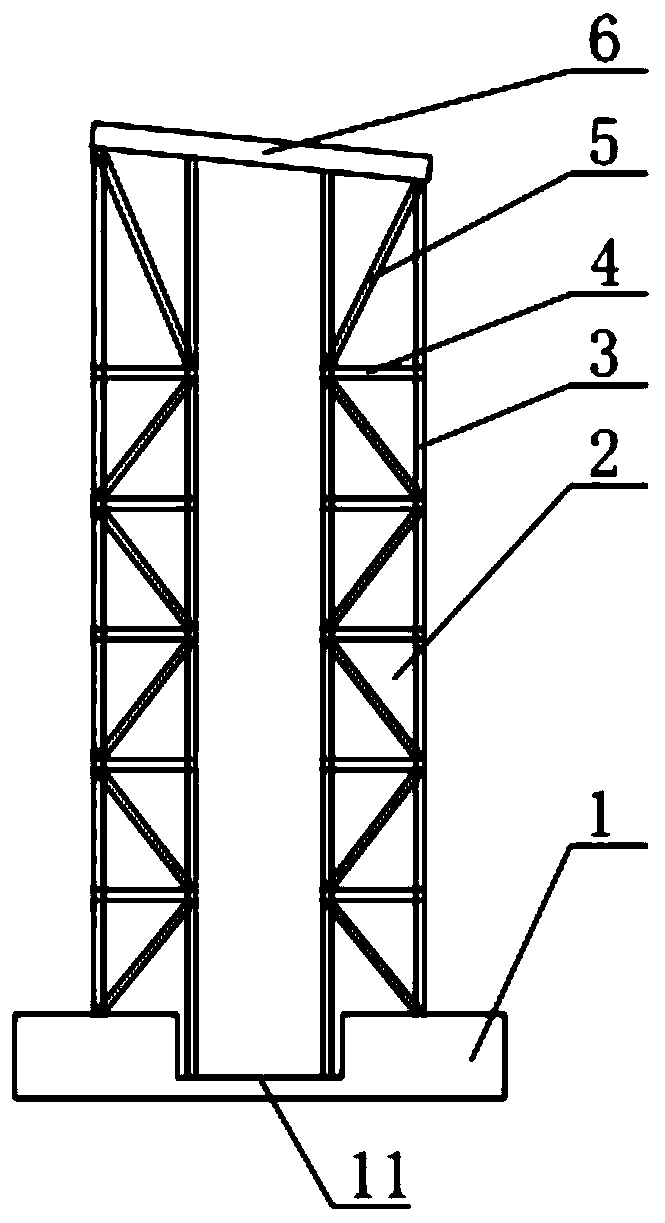

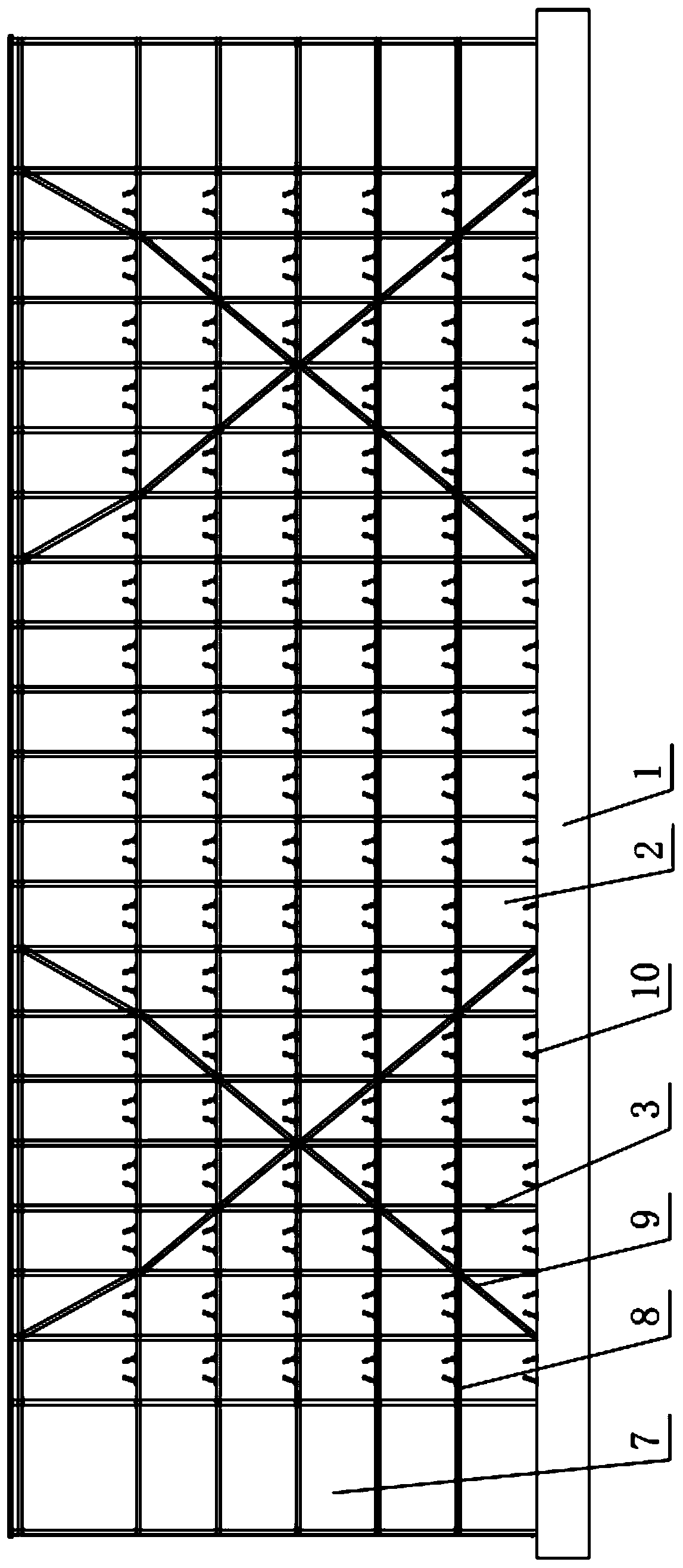

[0029] Such as figure 1 and figure 2 As shown, the three-dimensional horizontal storage rack for electrical steel raw coils for iron cores in this embodiment includes two rows of racks with intervals relatively set up on the ground 1. A plurality of main beams 8 are installed on the columns 3, and side beams 4 are fixed in an array between two rows of columns 3; saddles 10 are installed between the two laterally adjacent side beams 4, and the saddles 10 lie on top of each other. The electrical steel coil 106 is placed in the same way to form a storage unit 2; an inclined top beam 6 is installed on the top of the two rows of shelves. 6 Inclined settings to improve the drainage capacity of the shelf system.

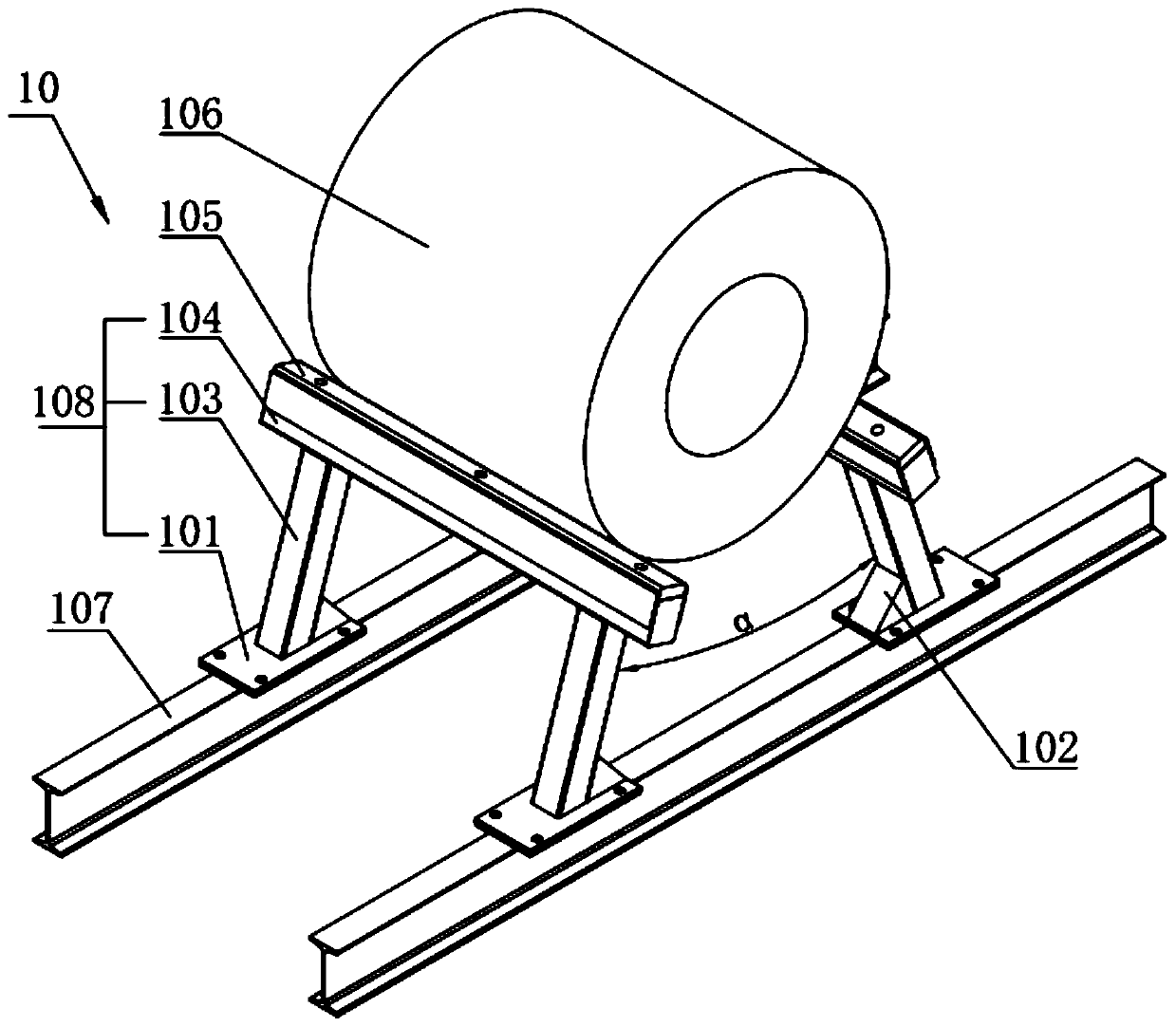

[0030] Such as image 3 As shown, the structure of a single saddle 10 is as follows: two bottom beams 107 are parallel at interva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com