Waste lead paste recycling processing method

A technology of recycling and waste lead paste, applied in the field of lead-acid batteries, can solve problems such as waste of resources, threats to the ecological environment and human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

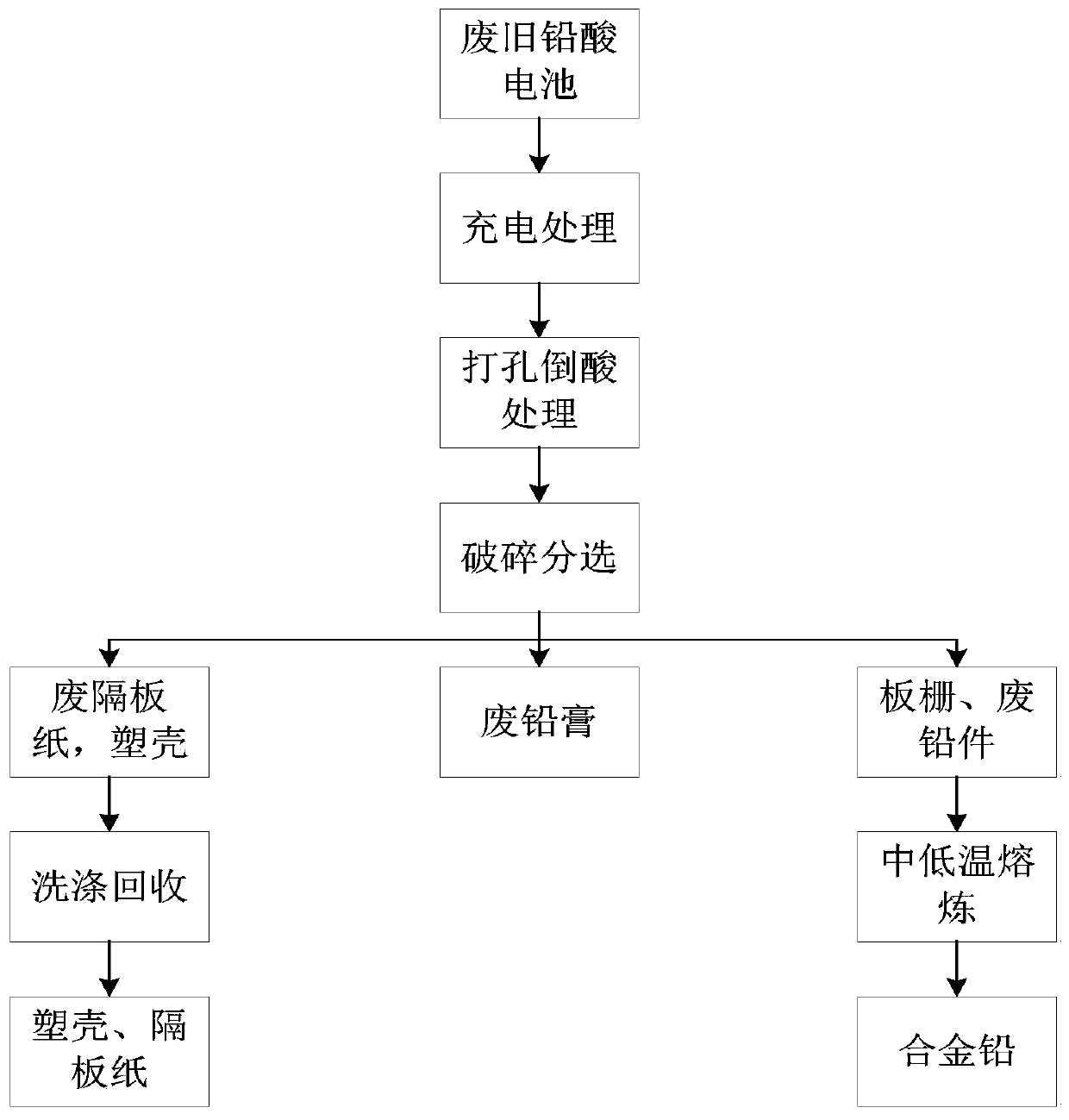

[0012] Such as figure 1 , the recovery flowchart of waste lead-acid battery of the present invention, the waste lead-acid battery recovery method step of the present invention is as follows:

[0013] (1) Used batteries are charged in series

[0014] Charge the waste lead-acid batteries in series at 0.15C current limit voltage 14.7V / only for 8-12h.

[0015] (2) Punching and acid pouring of waste lead-acid batteries

[0016] The cover of the fully charged waste lead-acid battery is punched, and the acid solution in the waste lead-acid battery is poured out and collected after punching, and the collected waste acid is directly used for the preparation of battery chemical acid after filtering and removing impurities.

[0017] (3) Crushing and sorting of waste batteries

[0018] After the waste lead-acid battery is broken by a crusher, the gravity flotation method is used to separate the lead paste, lead parts and grids, plastic cases and AGM separator paper. Plastic cases and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com