Baking equipment applied to drying of high-density fiberboards

A high-density fiberboard and drying equipment technology, applied in fiberboard, textiles, papermaking, papermaking, etc., can solve the problems of manpower consumption, low drying efficiency, and poor drying effect, and achieve the effect of improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

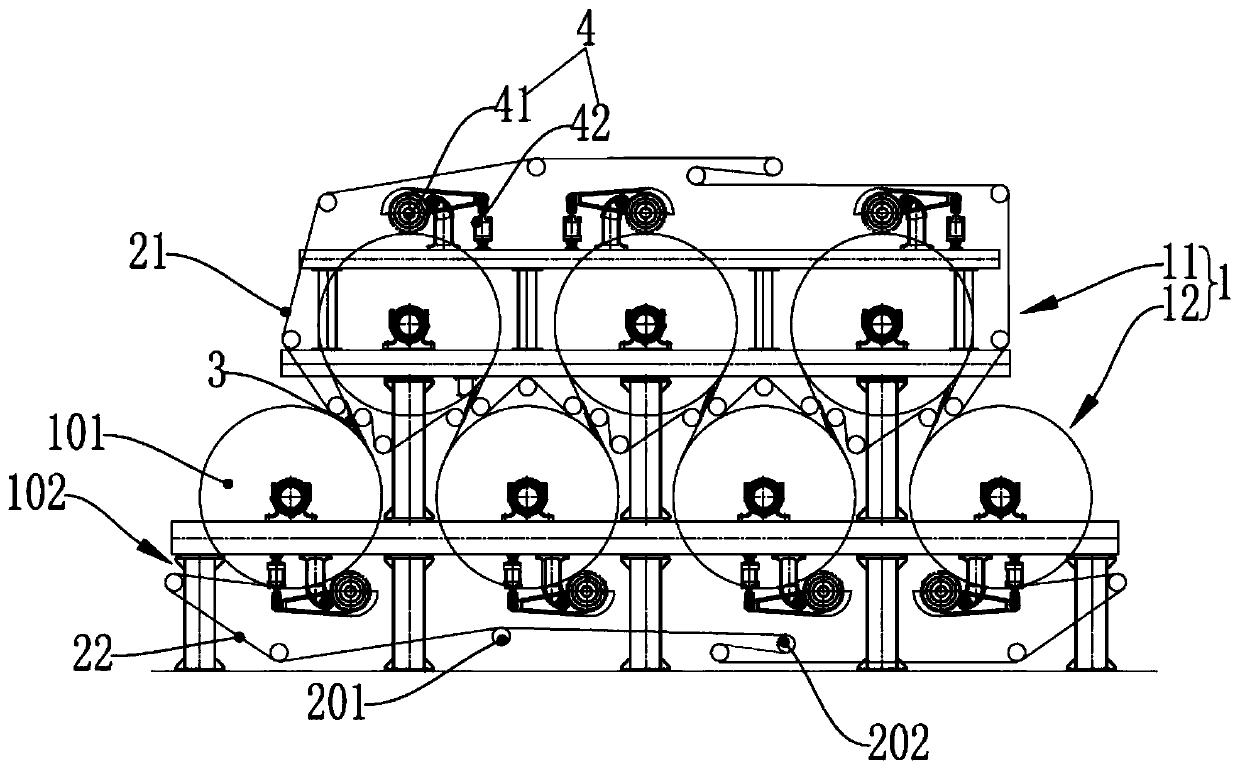

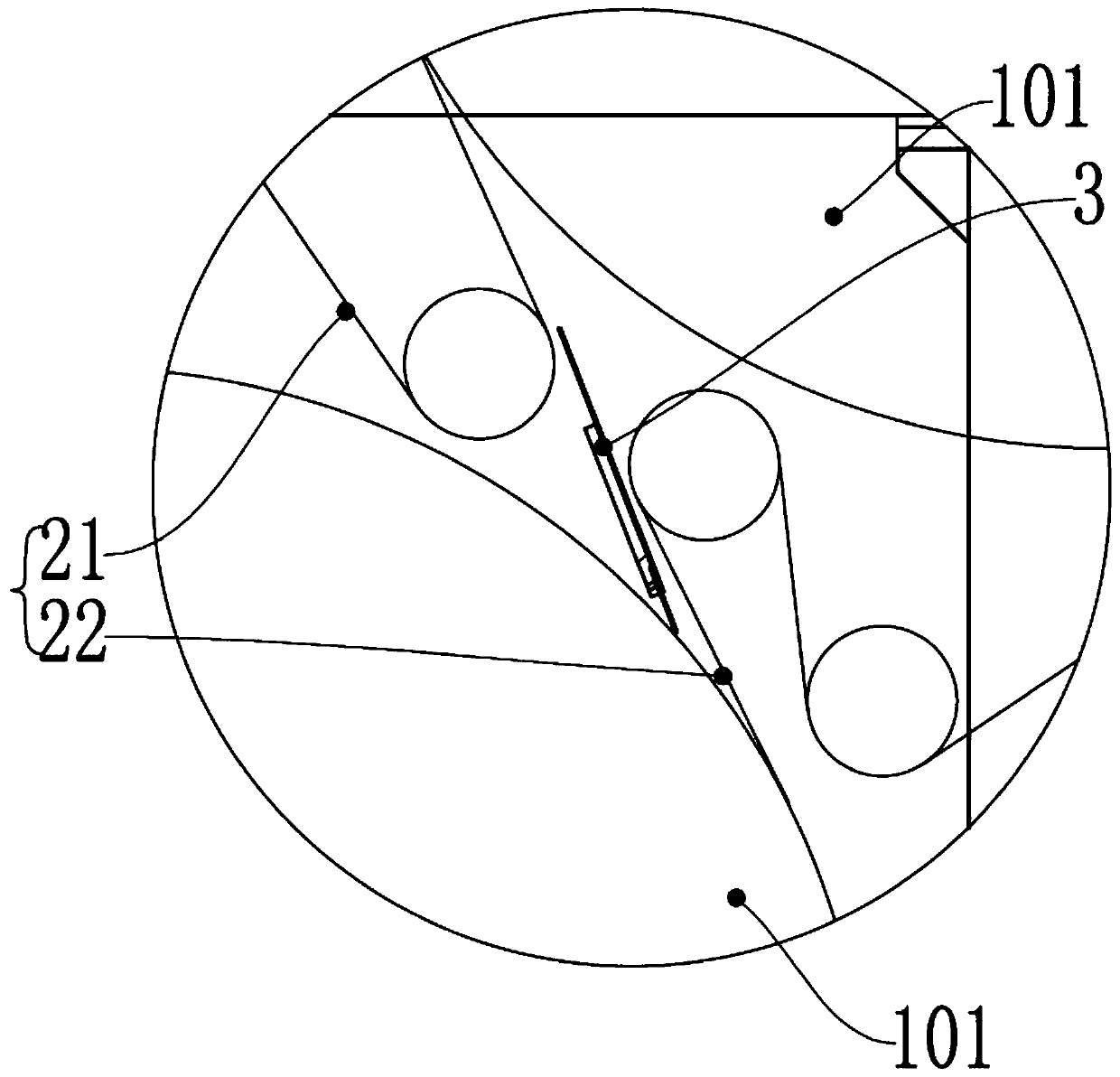

[0022] Such as Figure 1-2 As shown, a drying equipment applied to drying high-density fiberboard is characterized in that: it includes at least two layers of drying cylinders 1, conveyor belts 2 and guide plates 3 arranged up and down;

[0023] Each drying cylinder group 1 includes a plurality of horizontally arranged drying cylinders 101;

[0024] Each layer of the dryer group 1 is provided with an independent conveyor belt 2;

[0025] The guide plate 3 is provided at the connecting position of the two groups of conveyor belts 2 in the adjacent two-layer drying cylinder groups 1 .

[0026] In this embodiment, the drying cylinder equipment has two layers of drying groups 1, which are respectively an upper layer drying group 11 and a lower layer drying group 12; wherein the upper layer drying grou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap