Magnetic oil well optical cable capable of being adsorbed on inner side of metal pipe wall of oil and gas well

A metal tube and magnetic suction technology, applied in wellbore/well components, optical fiber/cable installation, optics, etc., can solve problems such as the inability to adhere to the inner wall of the casing and increase the loss of sound wave energy, so as to reduce losses and increase Acoustic wave sensitivity, the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

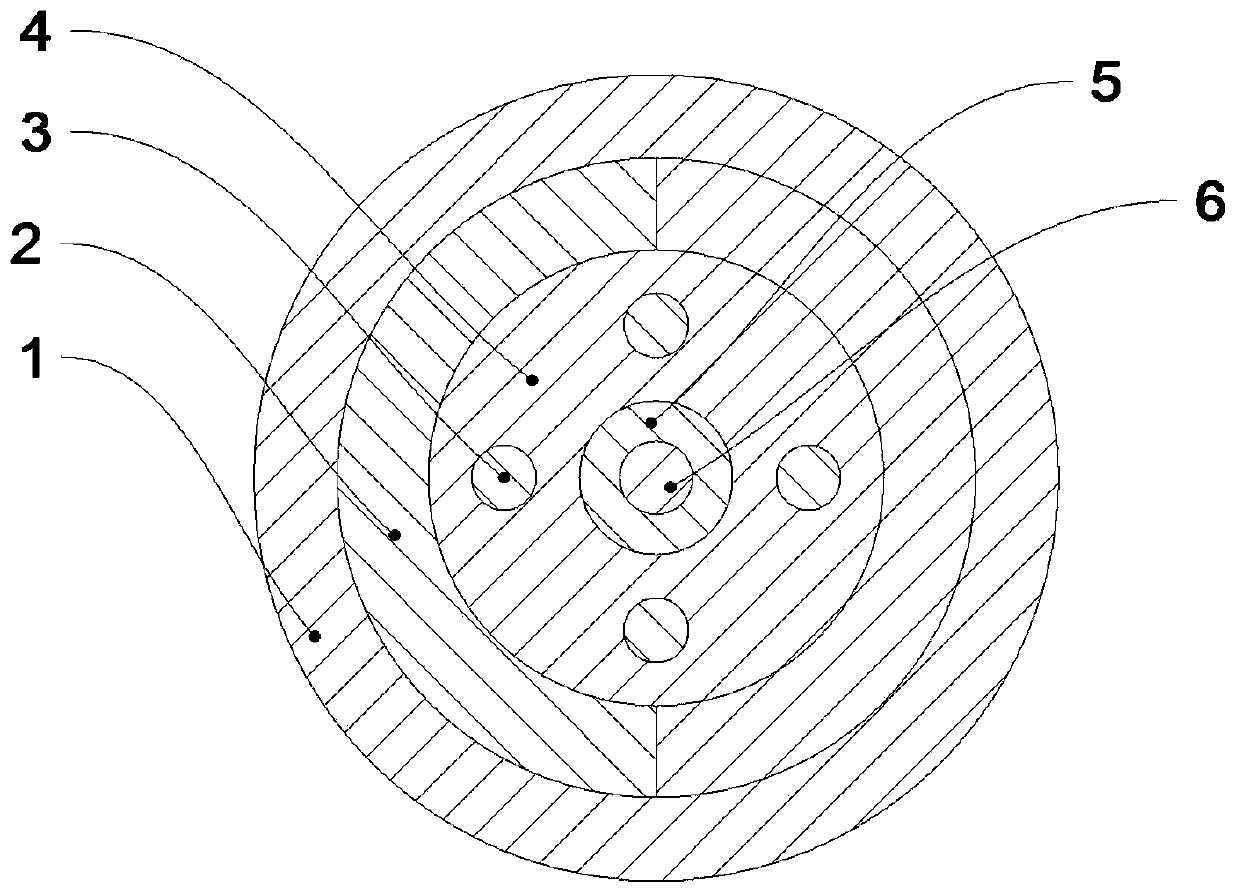

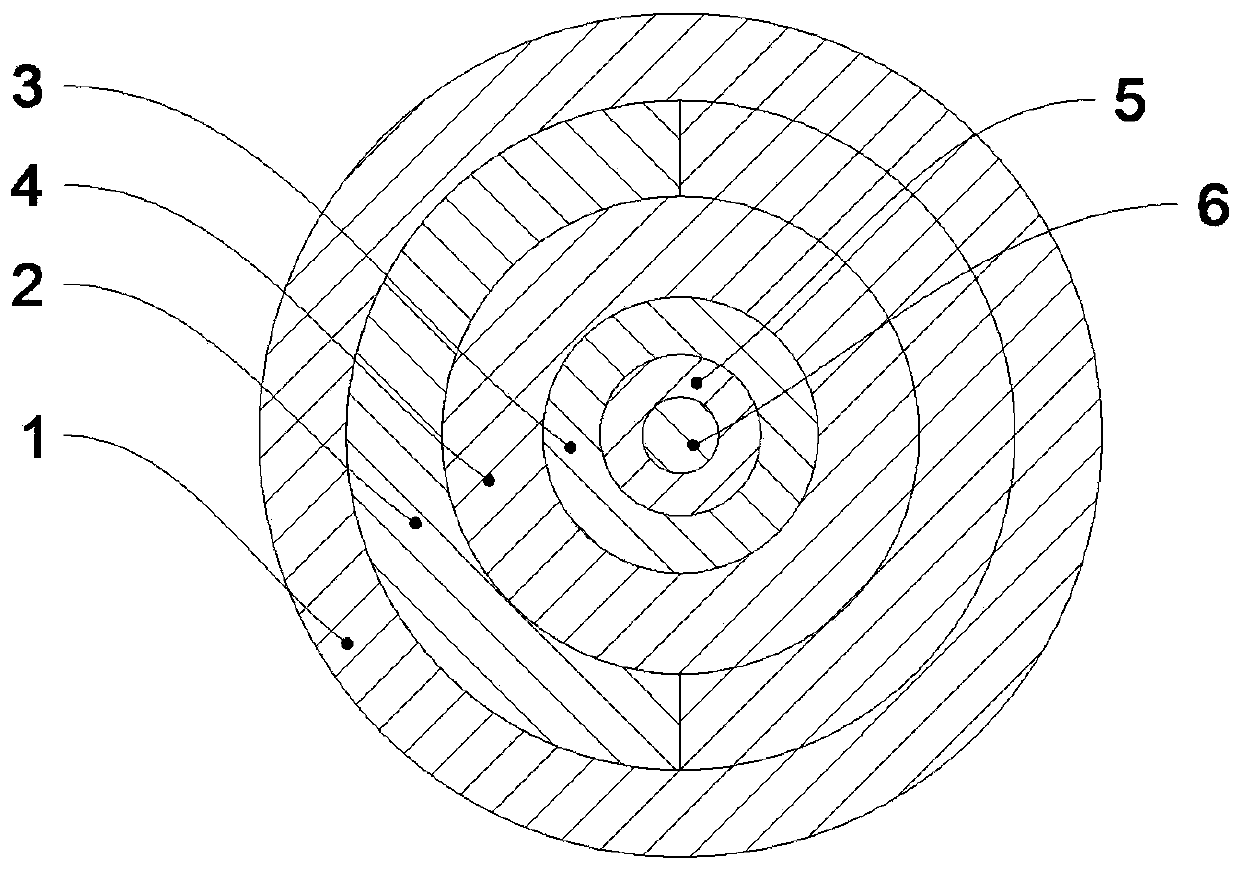

[0032] Such as Figure 1-6 As shown, a magnetic oil well optical cable that can be adsorbed on the inner side of the metal pipe wall of an oil and gas well includes a coated optical fiber 6, and a tight cladding 5 is attached to the outer surface of the coated optical fiber 6, and the outer surface of the tight cladding 5 A reinforcement layer is attached to the upper surface, and an adsorption element capable of absorbing the sleeve is attached to the outer surface of the reinforcement layer, and a protective layer 1 is attached to the outer surface of the adsorption element.

[0033] Working principle: When the optical cable is passed through the sleeve, since the optical cable is equipped with an adsorption element that can absorb the sleeve, the optical cable is tightly attached to the inner wall of the sleeve by using the adsorption force of the adsorption element on the sleeve. When the external sound wave When the energy is transferred to the casing, the acoustic energy...

Embodiment 2

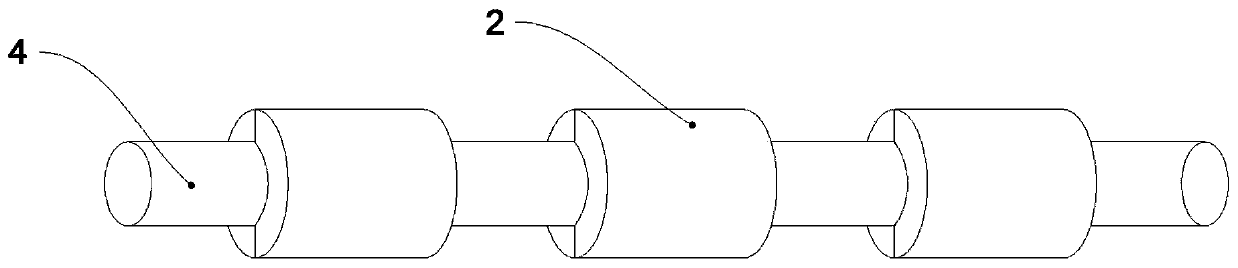

[0036] Such as Figure 1-4 As shown, on the basis of Example 1, this embodiment provides a preferred mechanism of the adsorption element, that is, the adsorption element is a plurality of sets of magnet assemblies 2 wrapped on the outer surface of the reinforcement layer, and the plurality of sets of magnet assemblies 2 are coated along the The length direction of the optical fiber 6 is distributed at intervals.

[0037] Preferably, the magnet assembly 2 includes a left semicircular magnet 21 and a right semicircular magnet 22, and the left semicircular magnet 21 and the right semicircular magnet 22 attract each other and are closely attached to the outer surface of the reinforcement layer.

[0038] Preferably, the length of the magnet assembly 2 is 5mm-30mm.

[0039]In this embodiment: the cross section of the left semicircular magnet 21 and the right semicircular magnet 22 can be a semicircular ring, and two magnets with the same shape and size attract each other to form a ...

Embodiment 3

[0042] Such as Figure 5-6 As shown, on the basis of Example 1, this embodiment provides another preferred structure of the adsorption element, that is, the adsorption element includes a strip-shaped film 7 attached to the reinforcement layer, and the strip-shaped film 7 is provided with a plurality of Thin magnet blocks 8 , a plurality of thin magnet blocks 8 are distributed at intervals along the length direction of the coated optical fiber 6 .

[0043] Preferably, the strip-shaped film 7 is a single-layer film, and a plurality of thin magnet blocks 8 are attached to the outer surface of the single-layer film; or the strip-shaped film 7 is a double-layer film, and a plurality of thin magnet blocks 8 are arranged in the double-layer film .

[0044] Preferably, the thickness of the thin magnet block 8 is 0.5mm-2mm, and the shape of the thin magnet block 8 is rectangular, circular or elliptical.

[0045] In this embodiment, the thin magnet block 8 can be packaged and fixed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com