Sheet thickness measuring instrument

A technology of thickness measurement and plate, which is applied in the direction of mechanical thickness measurement, force/torque/power measuring instrument, measuring device, etc., can solve the problem that the thickness of the plate cannot be measured, and achieve the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

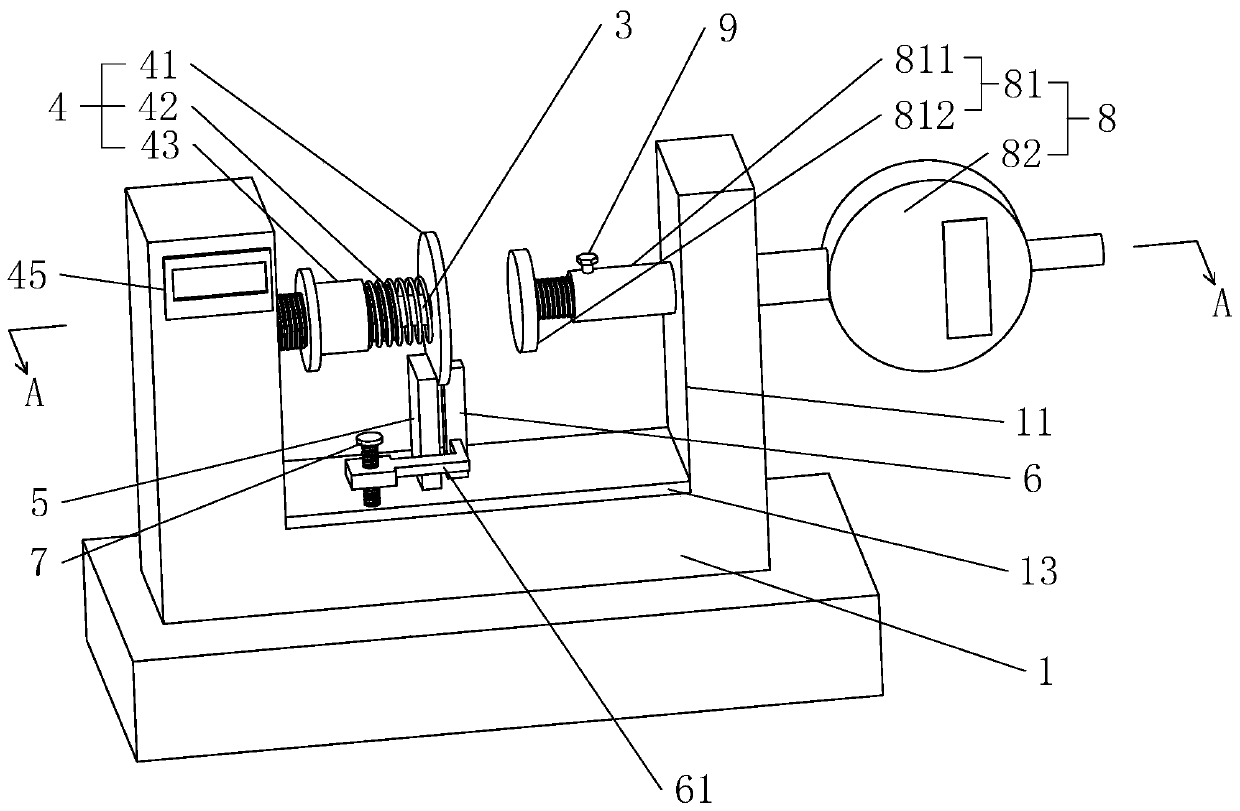

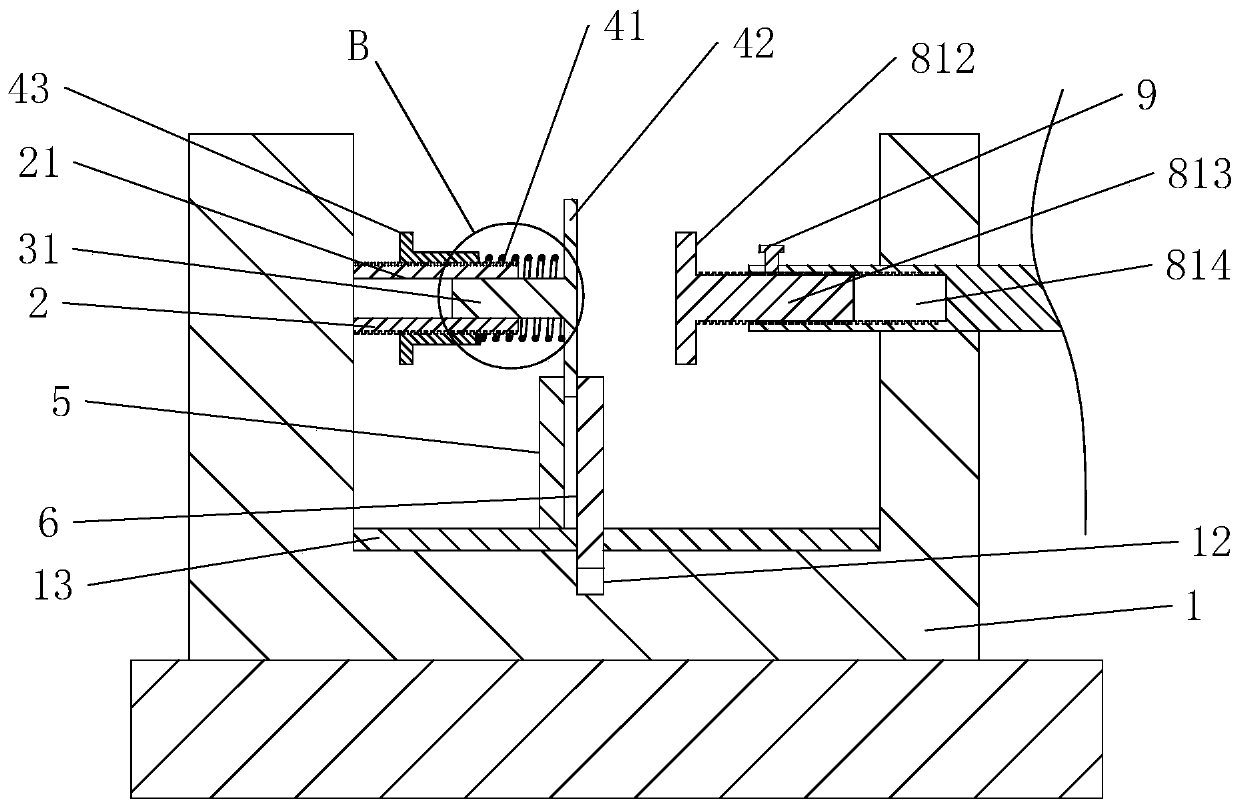

[0035] refer to figure 1 with figure 2 , is a plate thickness measuring instrument disclosed in the present invention, comprising a base 1, a measuring groove 11 is opened on the base 1, the measuring groove 11 runs through two opposite surfaces of the base 1, and the side wall of the measuring groove 11 is installed There is a connecting sleeve 2, the connecting sleeve 2 is arranged horizontally and is perpendicular to the measuring groove 11, the end of the connecting sleeve 2 is provided with a sliding hole 21, and there is a sliding rod 31 sliding in the sliding hole 21, the sliding rod 31 A first measuring arm 3 is integrally provided on one end protruding from the sliding hole 21 .

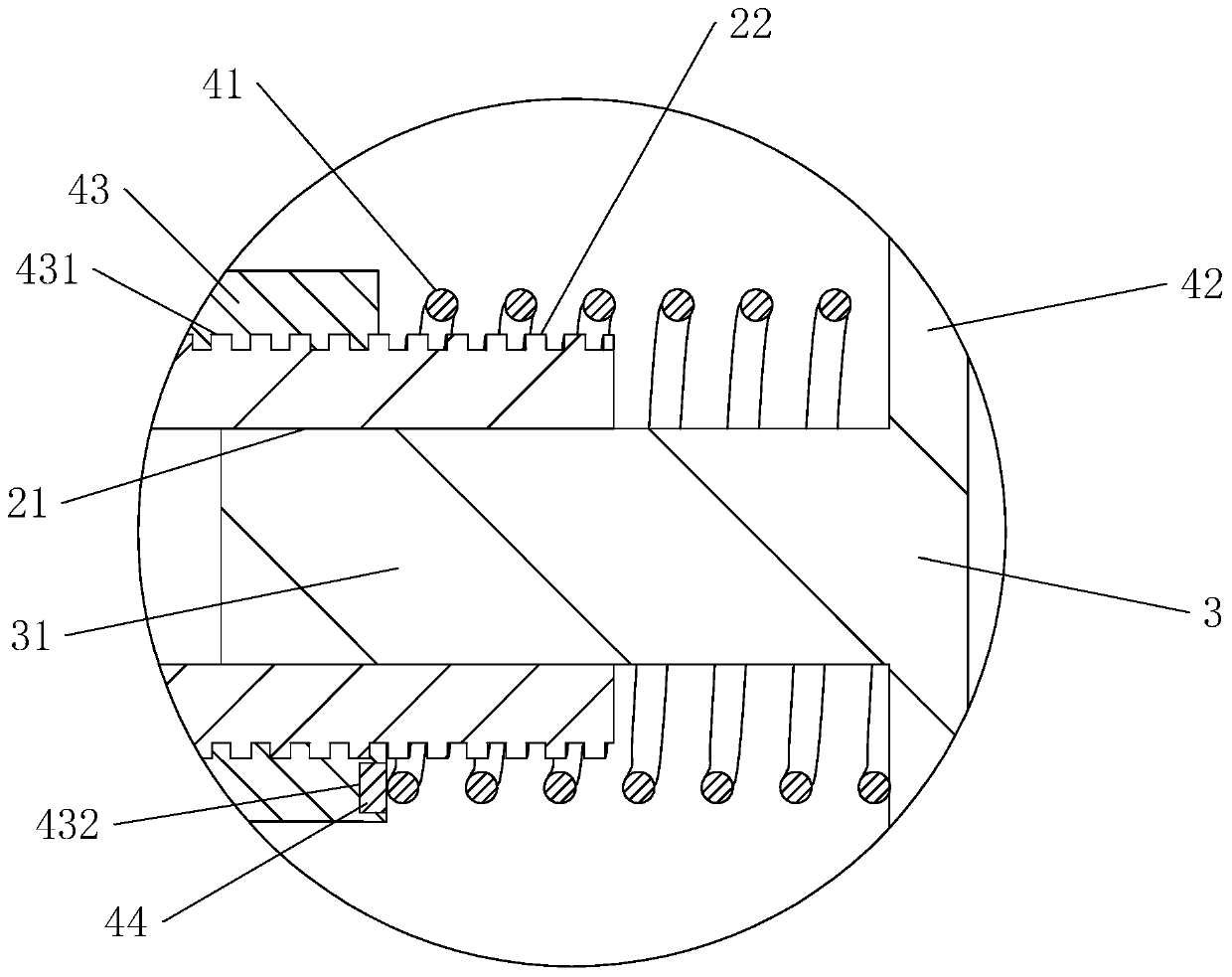

[0036] A pressurizing device 4 is provided on the first measuring arm 3 , and the pressurizing device 4 includes a spring 41 , a protruding ring 42 and a pressurizing sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com