Apparatus and method for testing resistance between uninsulated coil turns

A technology of resistance testing and coil turns, which is applied in the field of non-insulated coil inter-turn resistance testing devices, can solve the problems of huge workload, high price of superconducting strips, and uneconomical problems, and achieve the reduction of consumables, saving of superconducting strips, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

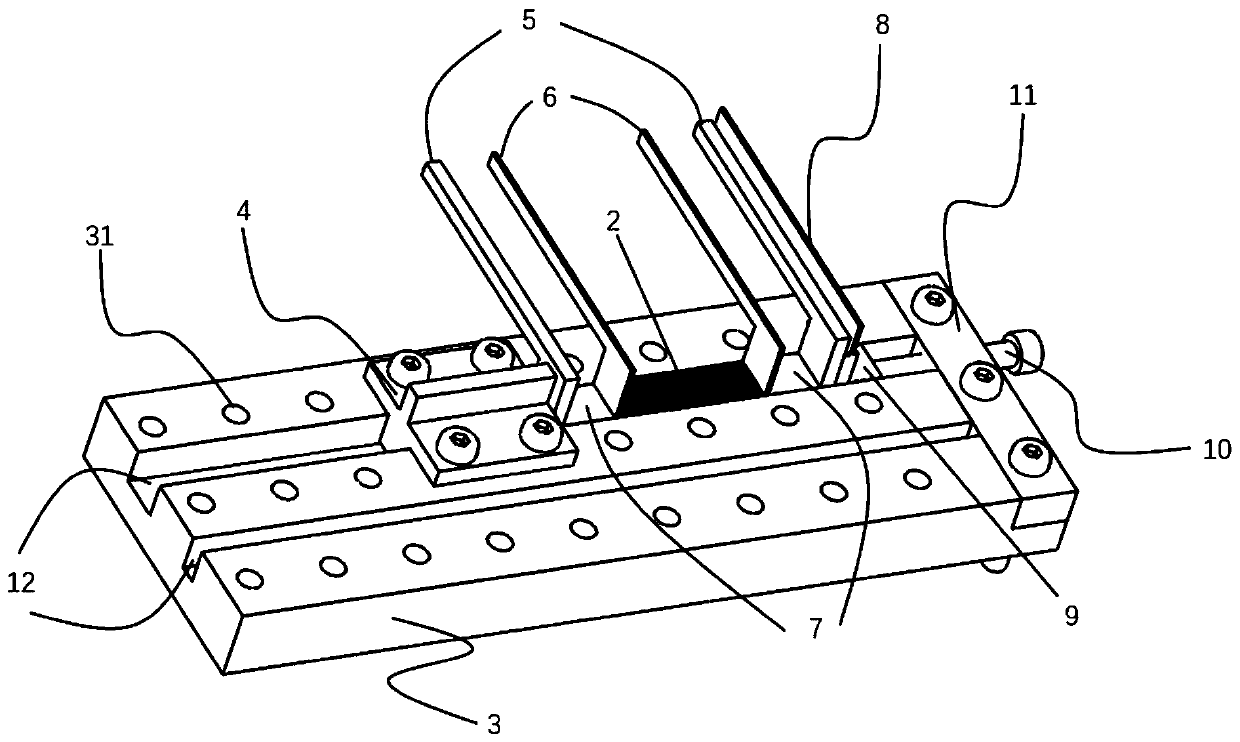

[0039] The invention provides a non-insulated coil turn-to-turn resistance test device, which includes a bottom plate 3, a first baffle plate 4, a current lead 5, a voltage lead 6, a conductive column 7, a pressure push block 9, a pressure regulating screw 10 and a second stop plate 11;

[0040] The bottom plate 3 is provided with an accommodating groove 12, the first baffle plate 4 and the second baffle plate 11 are arranged at a certain distance along the axial direction of the accommodating groove 12, and the pressure push block 9 is placed In the accommodating groove 12 between the first baffle plate 4 and the second baffle plate 11 , the pressure regulating screw 10 extends through the second baffle plate 11 into the accommodating groove 12 Connect with the pressure push block 9;

[0041] The current lead 5, the conductive column 7 and the voltage lead 6 are arranged in the accommodating groove 12 between the first baffle plate 4 and the pressure pushing block 9 in a mir...

Embodiment 2

[0055] The present invention provides a method for testing the interturn resistance of a non-insulated coil, by using the non-insulated coil interturn resistance test device described in the above-mentioned embodiment 1, comprising the following steps:

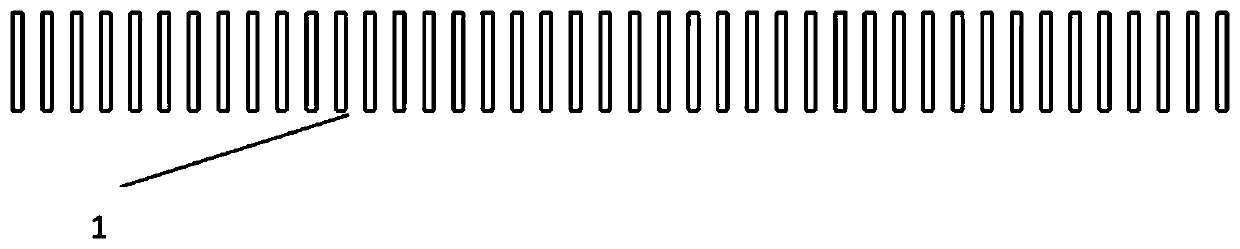

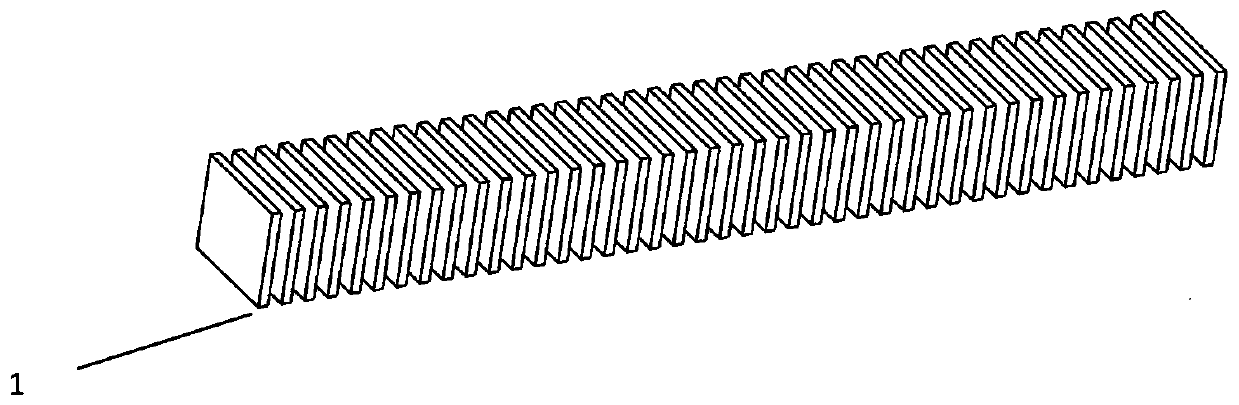

[0056] S1, preparing several test strip sheets 1, and stacking the test strip sheets to form a test strip 2;

[0057] S2. Put the test strip 2 into the accommodating groove 12 between the voltage leads 6;

[0058] S3, using the pressure regulating screw 10 to adjust the distance between the pressure push block 9 and the first baffle plate 4, so that the test strip 2 reaches a suitable pressure value;

[0059] S4. Put the non-insulated coil turn-to-turn resistance testing device into the low temperature environment where the coil is actually used;

[0060] S5. Pass the current through the current lead 5, collect the voltage through the voltage lead 6, and gradually increase the current, and obtain the V-I curve after collectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com