Greenhouse temperature and humidity control device

A temperature and humidity control and humidity control technology, applied in non-electric variable control, control/regulation systems, and simultaneous control of multiple variables, etc., can solve the problems of insufficient fine-tuning, inconsistent temperature and humidity, etc., achieving high accuracy and reducing The effect of high workload and intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The greenhouse temperature and humidity control device of this embodiment includes a temperature and humidity acquisition module, a control module, a temperature regulation module and a humidity regulation module.

[0039] The temperature and humidity collection module is used to collect temperature data and humidity data; each area of the greenhouse corresponds to a temperature and humidity collection module; in this embodiment, the temperature and humidity collection module uses a temperature and humidity sensor. Specifically, a DHT11 digital temperature and humidity sensor is used.

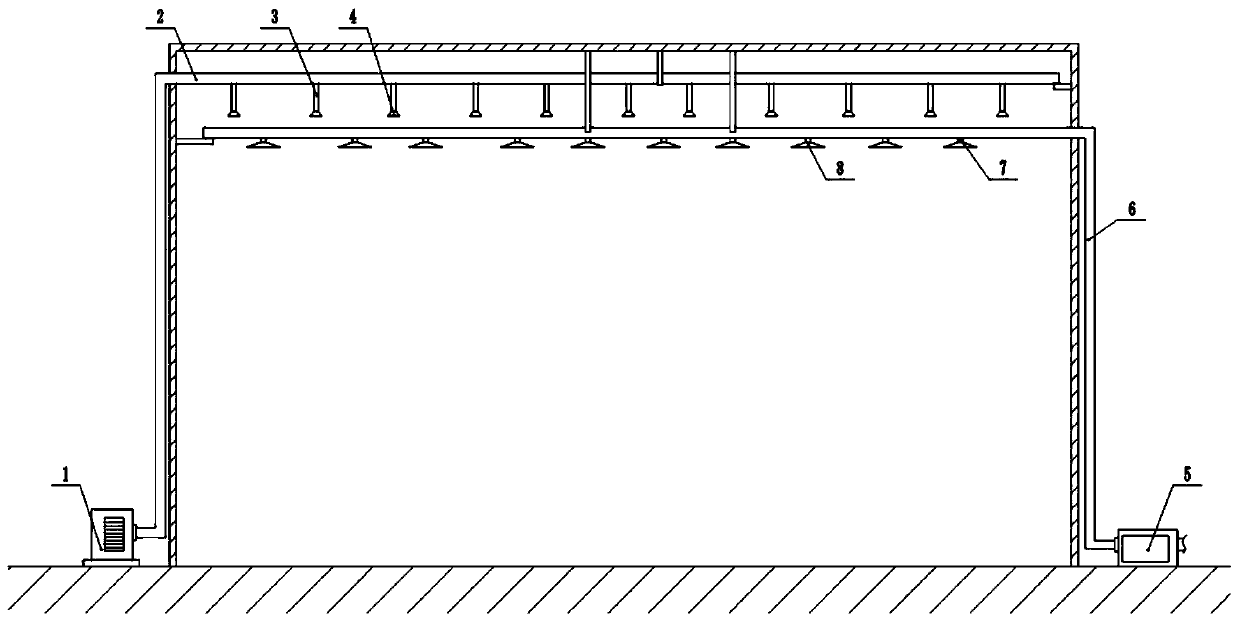

[0040] like figure 1 As shown, the temperature adjustment module includes a hot air blower 1, a main air delivery pipe 2, several auxiliary air delivery pipes 3, a hot air nozzle 4 and a hot air control valve. Hot air blower 1 is installed on the ground of greenhouse, can be installed in the outside of greenhouse, also can be installed in the inside of greenhouse. The auxiliary air d...

Embodiment 2

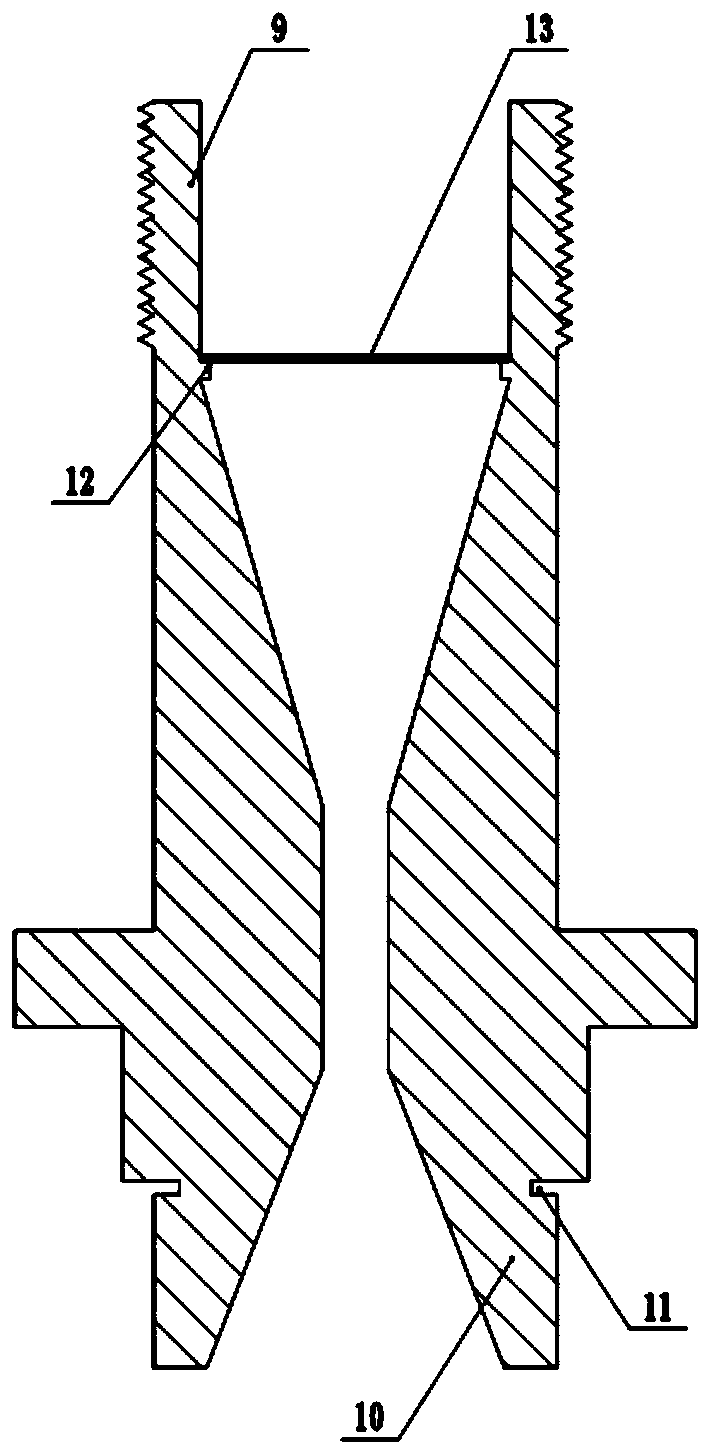

[0052] The difference between this embodiment and Embodiment 1 is that the atomizing nozzle 8 in this embodiment includes a funnel-shaped water inlet 9 and a water outlet 10 ; the water inlet 9 and the water outlet 10 are connected. Specifically, such as figure 2 As shown, when the atomizing nozzle 8 is placed vertically, the water inlet 9 is in the shape of a funnel placed upright, the water outlet 10 is in the shape of an inverted funnel, and the outer wall of the water inlet 9 is integrally formed with external threads; the outer wall of the water outlet 10 is provided with Ring groove 11. When it is necessary to install the annular cover on the atomizing nozzle 8, the annular cover can be embedded in the annular groove 11 to realize fixing.

[0053] The inner wall of the water inlet 9 is also integrally formed with an annular protrusion 12; a circular filter 13 is placed horizontally in the water inlet 9, and the filter 13 is matched with the inner wall of the water inle...

Embodiment 3

[0056] The difference between this embodiment and Embodiment 1 is that this embodiment also includes a connection module.

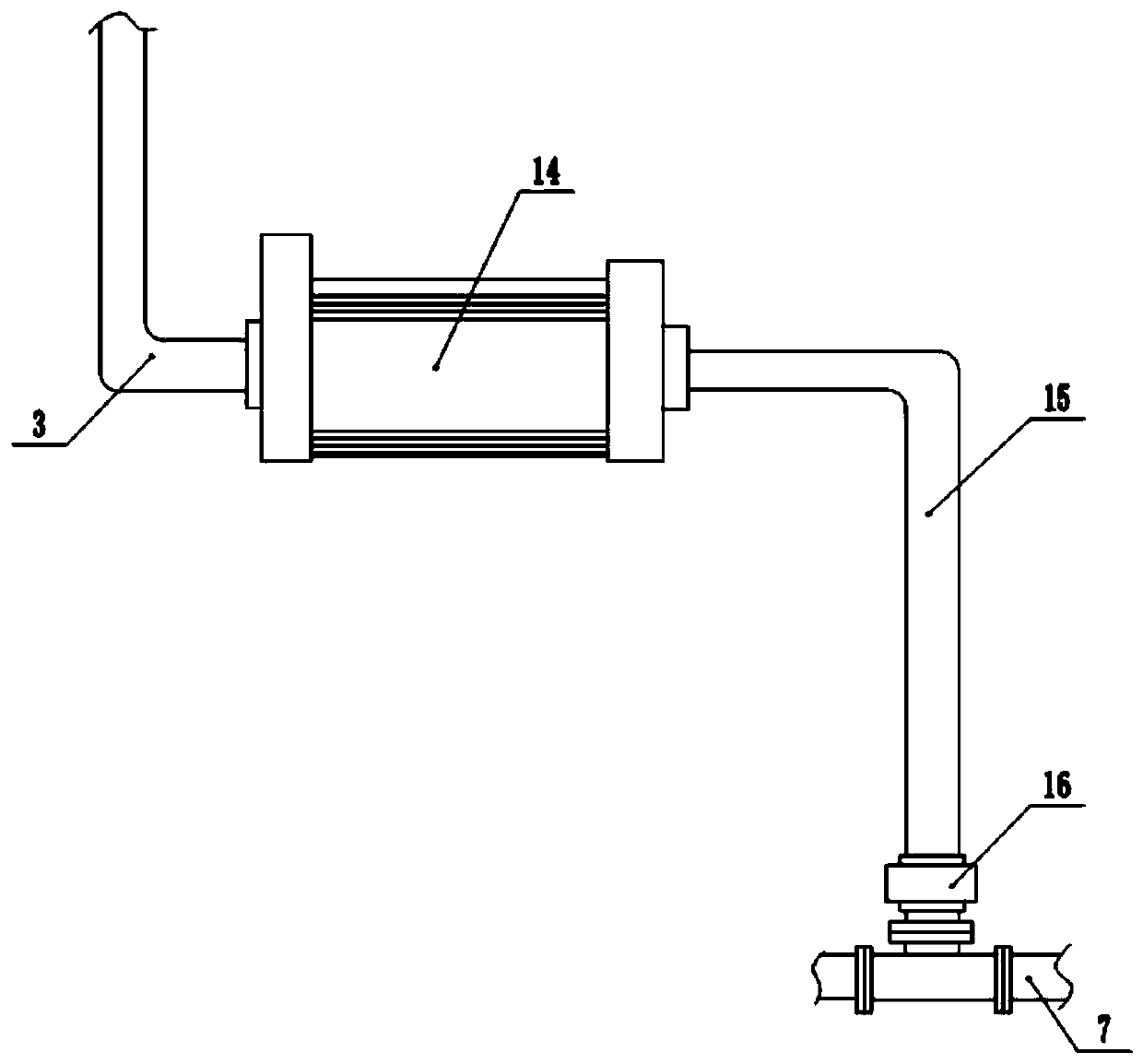

[0057] like image 3 As shown, the connection module includes an air booster pump 14, a connecting pipe 15 and a check valve 16; the air booster pump 14 includes an air inlet port and an exhaust port; the check valve 16 includes an inlet port and an outlet port; the air booster pump The air inlet end of 14 is flange-connected with the auxiliary air delivery pipe 3, specifically, the upper flange of the auxiliary air delivery pipe 3 is connected with a three-way pipe, and the air inlet end of the air booster pump 14 is flange-connected with one end of the three-way pipe .

[0058] The exhaust end of the air booster pump 14 is flange-connected to one end of the connecting pipe 15, the other end of the connecting pipe 15 is flange-connected to the inlet end of the check valve 16, and the outlet end of the check valve 16 is fixed to the auxiliary water pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com