Threshing and redrying processing quality comprehensive evaluation method based on multivariate statistics

A technology for leaf threshing, re-roasting, and processing quality, which is applied in calculations, measuring devices, manufacturing calculation systems, etc., can solve the problems of weight and scoring methods that are slightly subjective, and achieve the effect of scientific evaluation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1 Materials and methods

[0035] 1.1 Material data

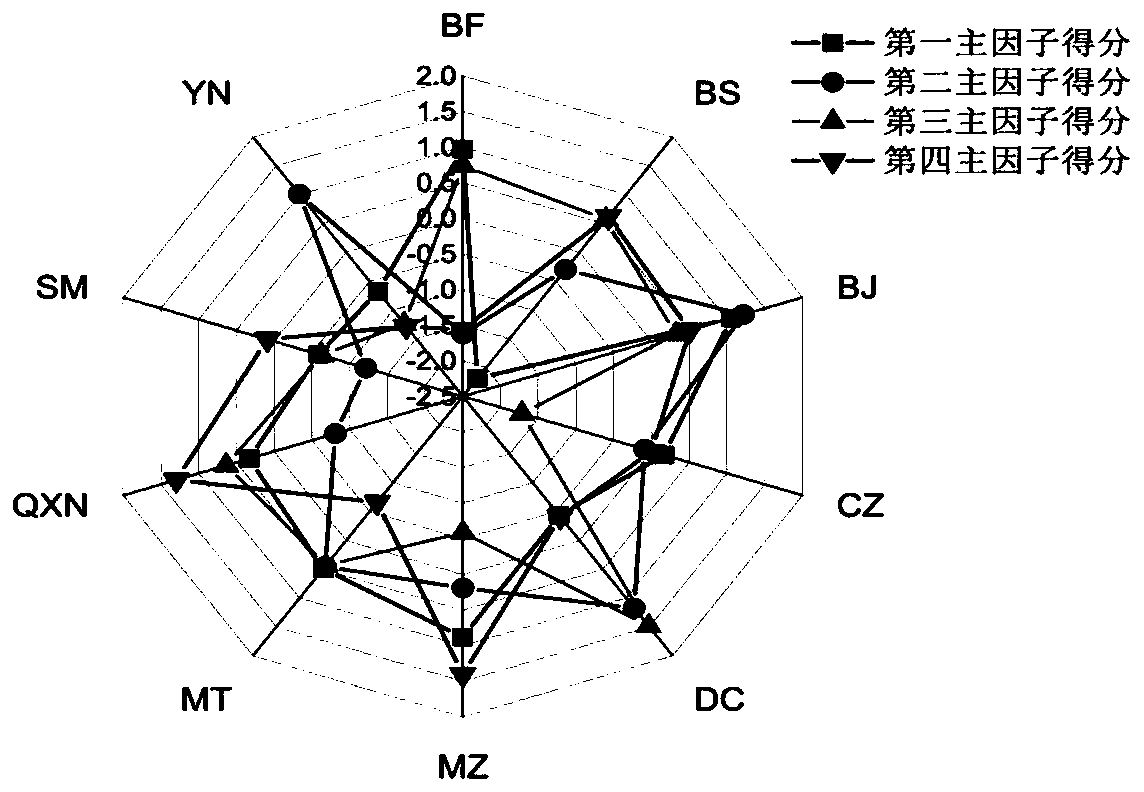

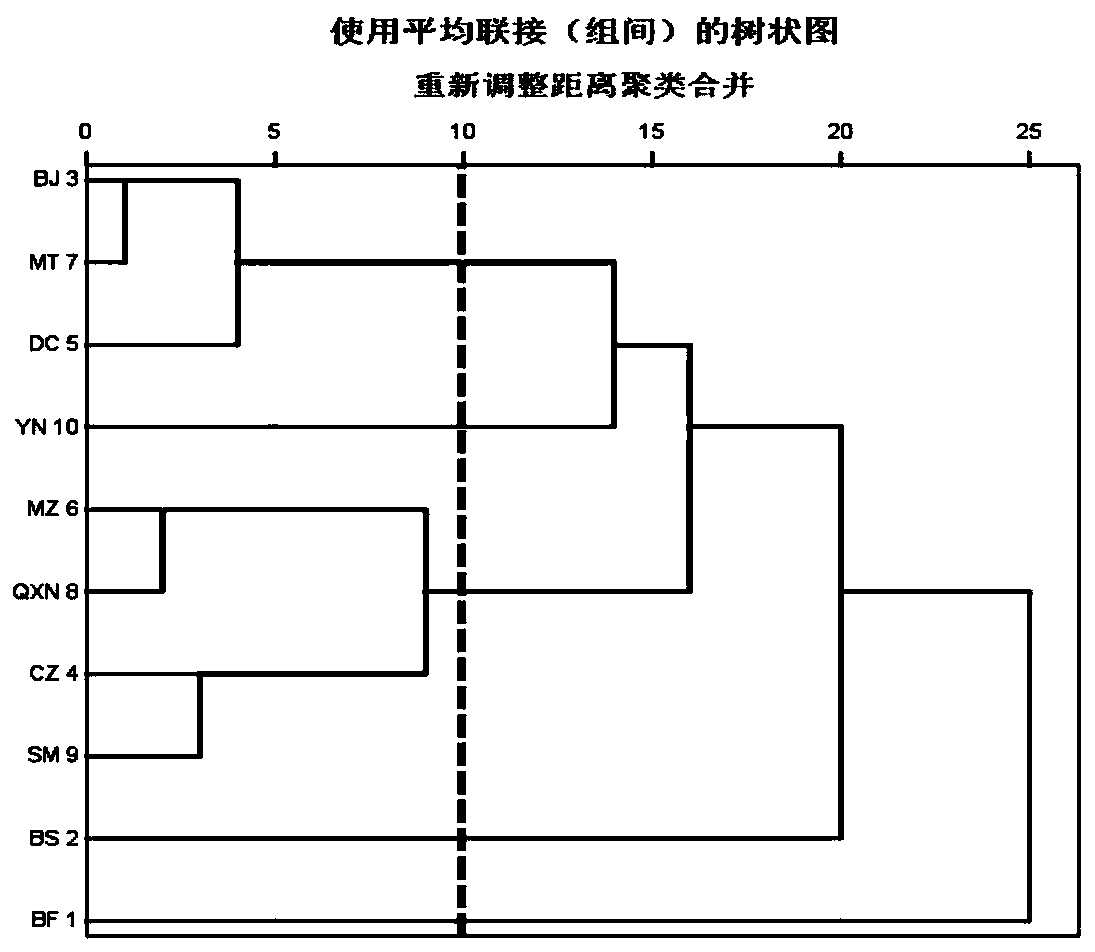

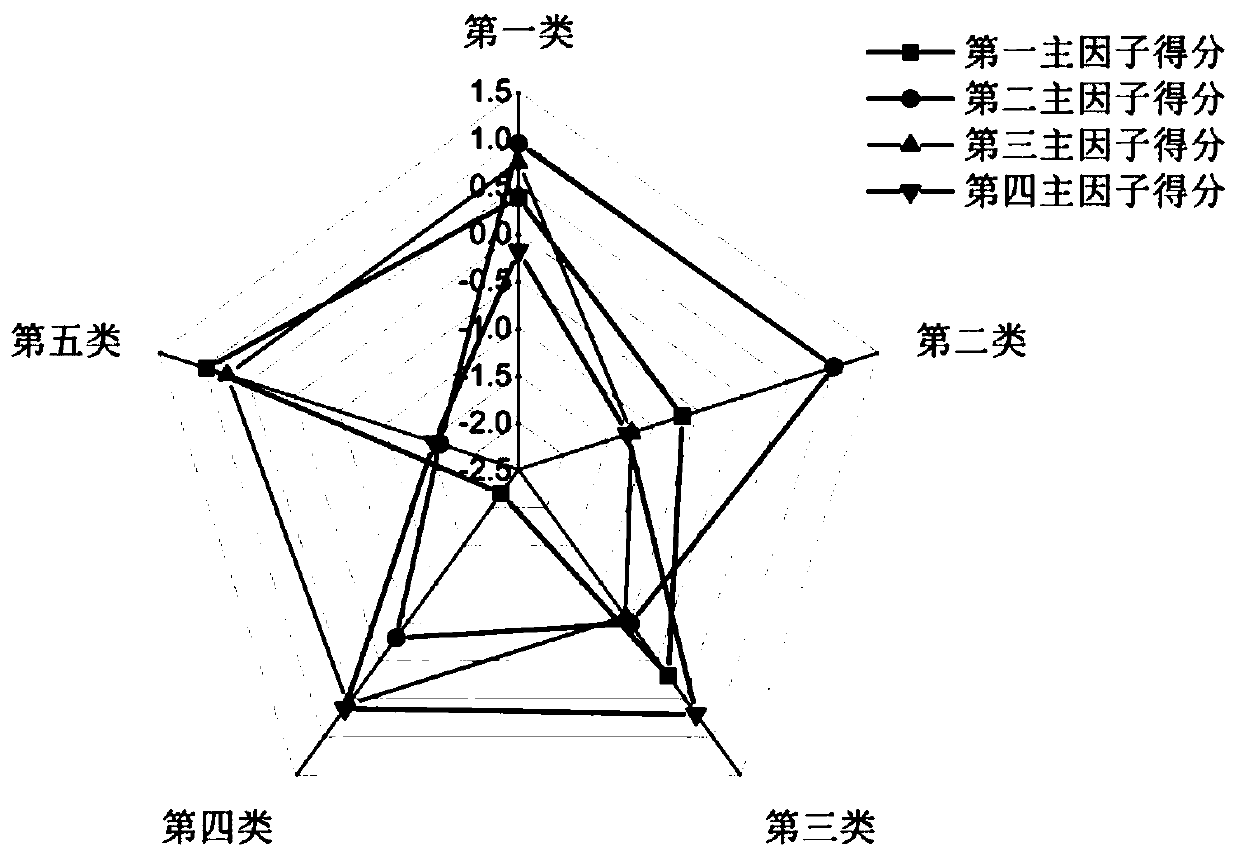

[0036] The data in this study were provided by China Tobacco Guizhou, including the processing quality data of 10 leaf threshing and redrying enterprises in the past three years (2015-2017), and each enterprise was named BF, BS, BJ, CZ, DC, MZ, MT , QXN, SM, YN.

[0037] Select the output rate of the upper-class tobacco module in the middle, the rate of large and medium-sized finished products (>12.7×12.7mm 2 ), finished product large rate (> 25.4×25.4mm 2 ), finished film rate (12.7×12.7-25.4×25.4mm 2 ), finished small piece rate (6.35×6.35-12.7×12.7mm 2 ), finished product fragment rate (2.36×2.36-6.35×6.35mm 2 ), finished product crushing rate (2 ), raw tobacco stem content rate, finished product leaf stem content rate, finished product stem leaf content rate, raw tobacco moisture content, and finished product moisture content, a total of 12 processing indicators were analyzed.

[0038] 1.2 Method

[0039] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com