High-pressure gas desorption visbreaking rotary tillage cutter, rotary tiller and rotary tillage method of rotary tiller

A technology of high-pressure gas and rotary tiller, which is applied in the fields of tillage implements, agricultural machinery and implements, etc. It can solve the problems of increased cutter resistance and reduced cutter life, so as to reduce friction, reduce tillage resistance and increase service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

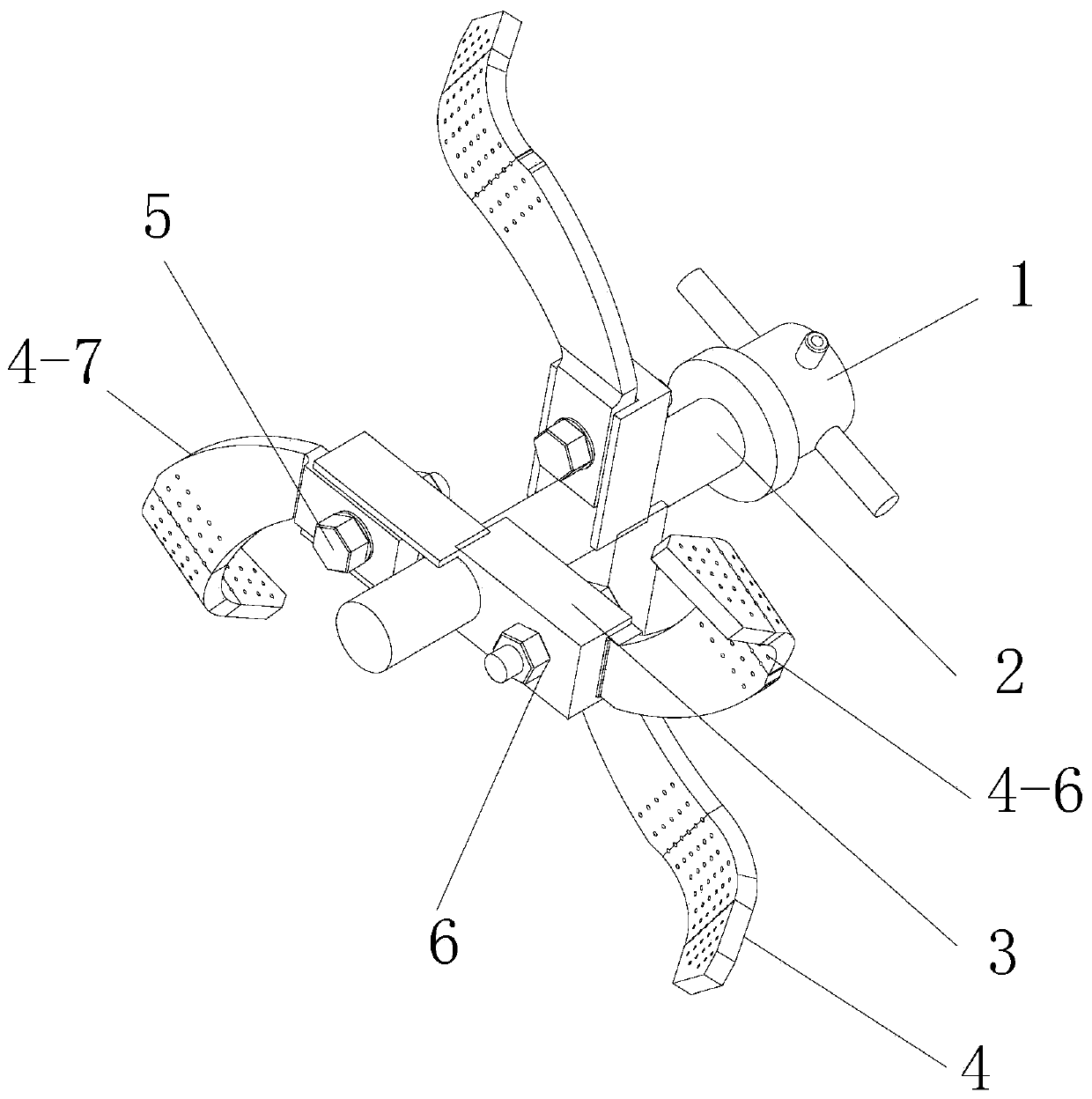

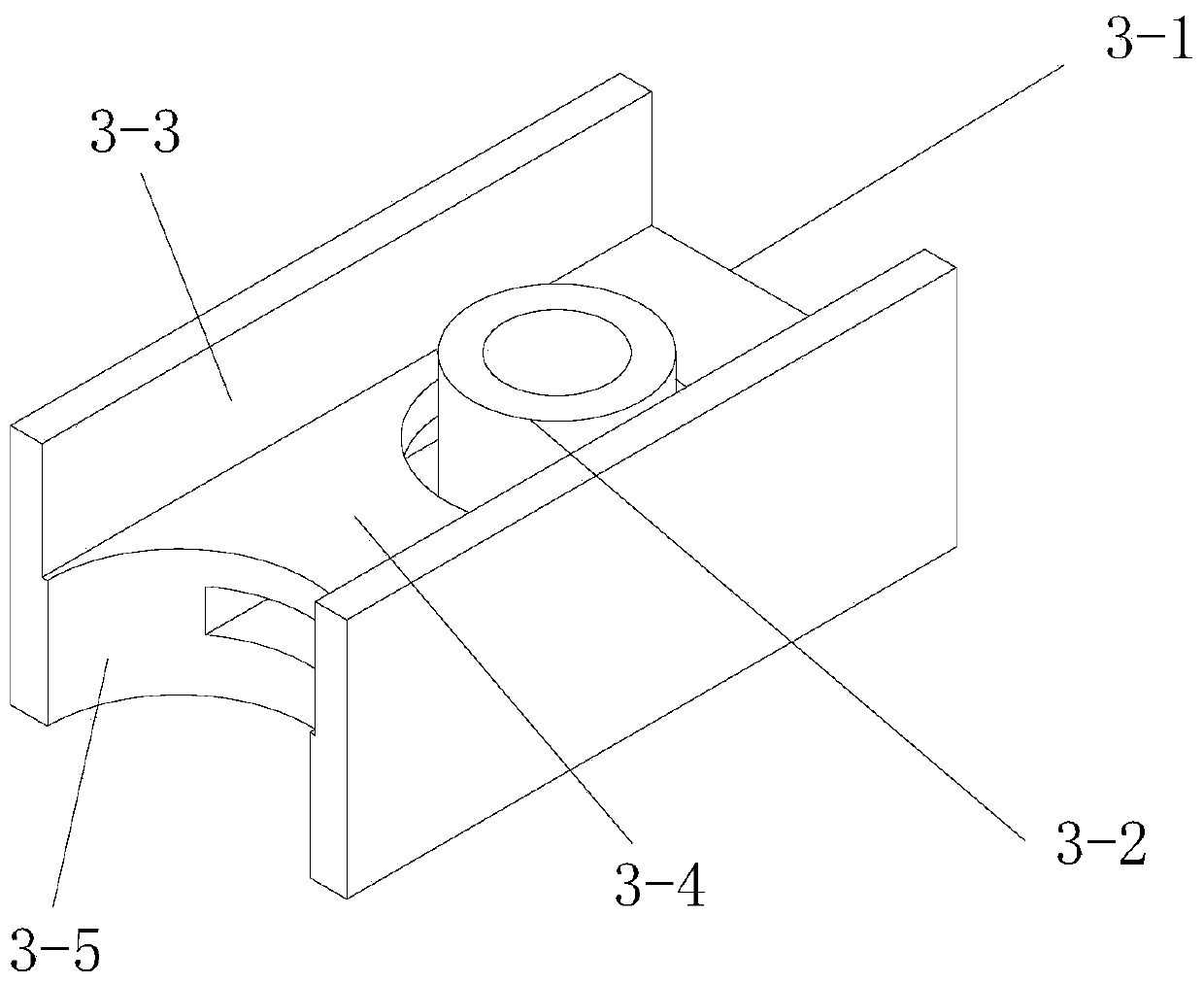

[0047] A high-pressure gas desorption and viscosity-reducing rotary tillage cutter head includes a pneumatic slip ring, a hollow cutter shaft, a cavity cutter holder, a hollow cutter, shoulder screws and nuts. The hollow knife shaft is connected to the machine frame in a rotating manner, and a pneumatic slip ring is installed between the hollow knife shaft and the machine frame. on the frame; the pneumatic slip ring, hollow cutter shaft, cavity tool holder, and hollow tool are all equipped with cavities, and the cavities of the pneumatic slip ring, hollow cutter shaft, cavity tool holder, and hollow tool are connected in sequence; on the pneumatic slip ring There is a trachea interface; the soil-contacting part of the hollow cutter is provided with multiple evenly distributed air outlets.

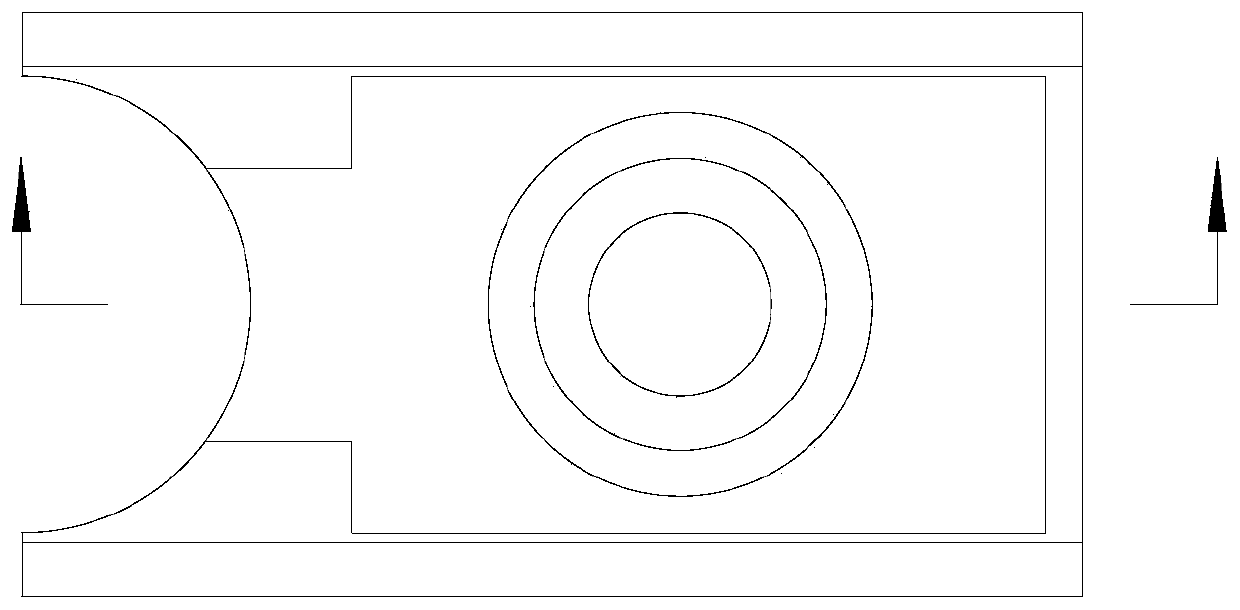

[0048] The pneumatic slip ring includes a stator part and a rotor part, the cavities of the stator part and the rotor part communicate with each other, and the rotor part rotates relative t...

Embodiment 2

[0056] A rotary tiller, comprising a gas source and a high-pressure gas desorption and viscosity-reducing rotary tiller disc of Embodiment 1; the gas source providing high-pressure gas is connected to the gas pipe interface of the pneumatic slip ring through a gas pipe.

[0057] A rotary tillage method of a rotary tiller, using a rotary tiller, high-pressure gas is ejected through the air outlet of the hollow cutter to blow the soil away, and at the same time, with the high-speed rotation of the rotary tiller, the high-pressure gas flows between the hollow cutter and the rotary tiller. An air film that reduces soil adhesion is formed between the soils, reducing soil adhesion.

[0058] The parts not mentioned in this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com