Water-based paint spraying device for furniture

A technology for water-based paint and furniture, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of poor product consistency and finished product difference, and achieve the effect of quick painting process and high consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

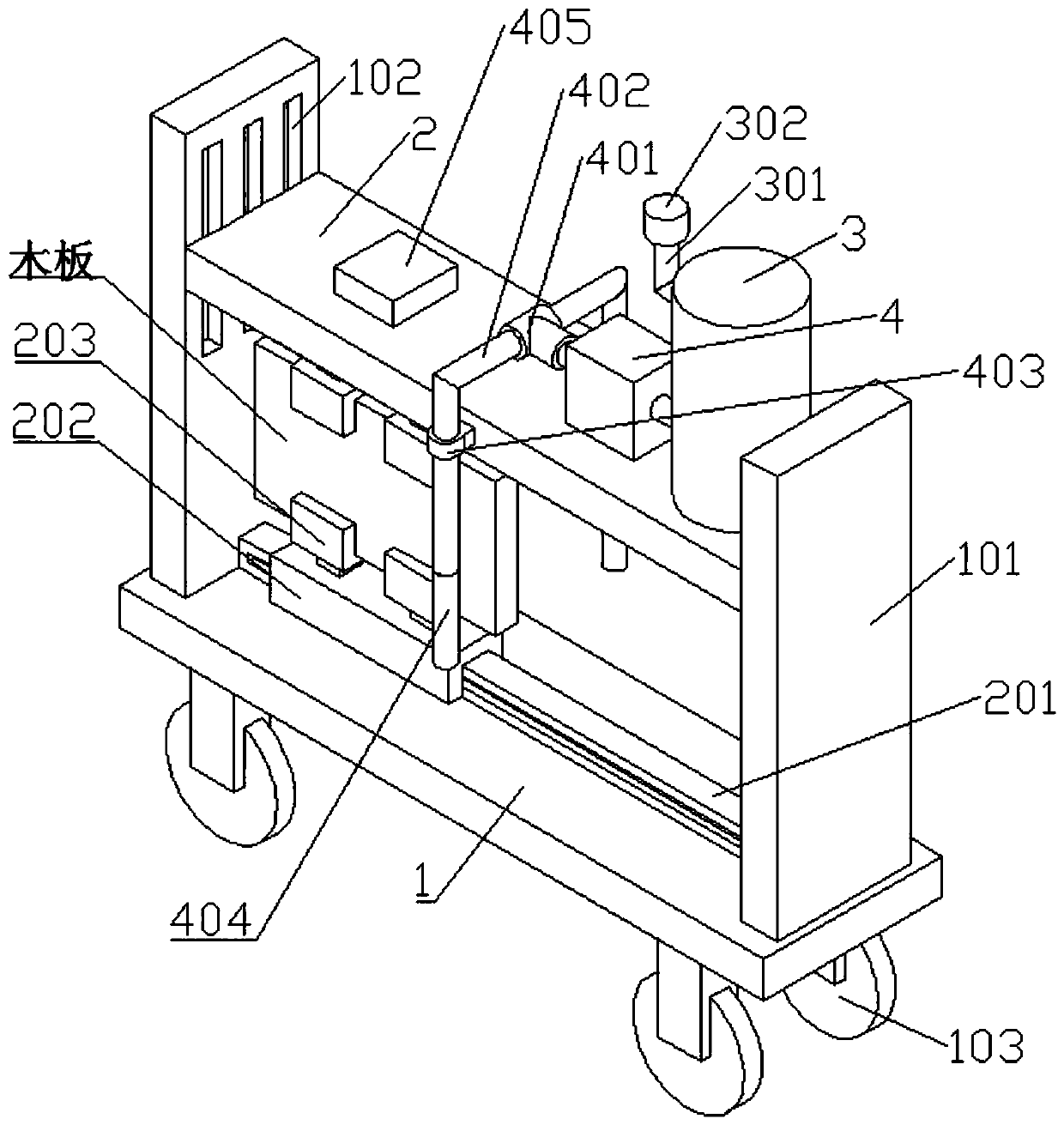

[0029] A water-based paint spraying device for furniture, comprising a seat plate 1, a lifting plate 2, a paint tube 3 and a paint pump 4;

[0030] The upper surface of the seat plate 1 is symmetrically fixed with support plates 101, and the upper inner wall of each support plate 101 is uniformly provided with vertical chute 102;

[0031] The two ends of the lifting plate 2 are slidably connected to the chute 102. The lower surface of the lifting plate 2 is fixed with a linear track 201, and the linear track 201 is also fixed at one place on the upper surface of the seat plate 1. The two linear tracks 201 are arranged symmetrically. The linear track 201 is slidably connected with a sliding seat 202, and the sliding seat 202 is symmetrically fixed with a fixed assembly 203;

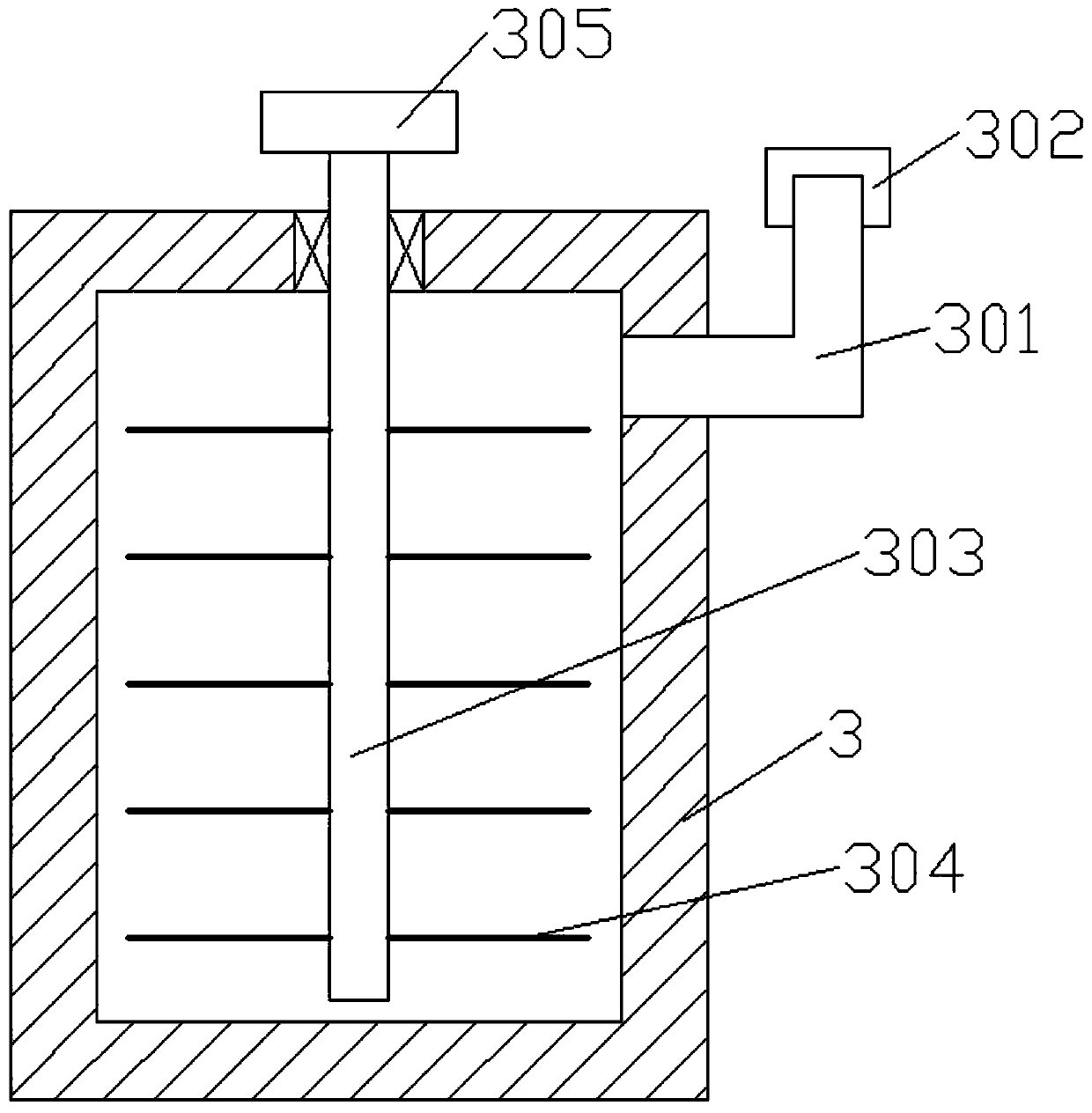

[0032] The paint tube 3 is fixedly connected to the upper surface of the lifting plate 2, the paint tube 3 is fixedly connected to a liquid feeding pipe 301, and the liquid feeding pipe 301 is threadedly c...

Embodiment 2

[0038] The difference from Example 1 is that it also includes the following:

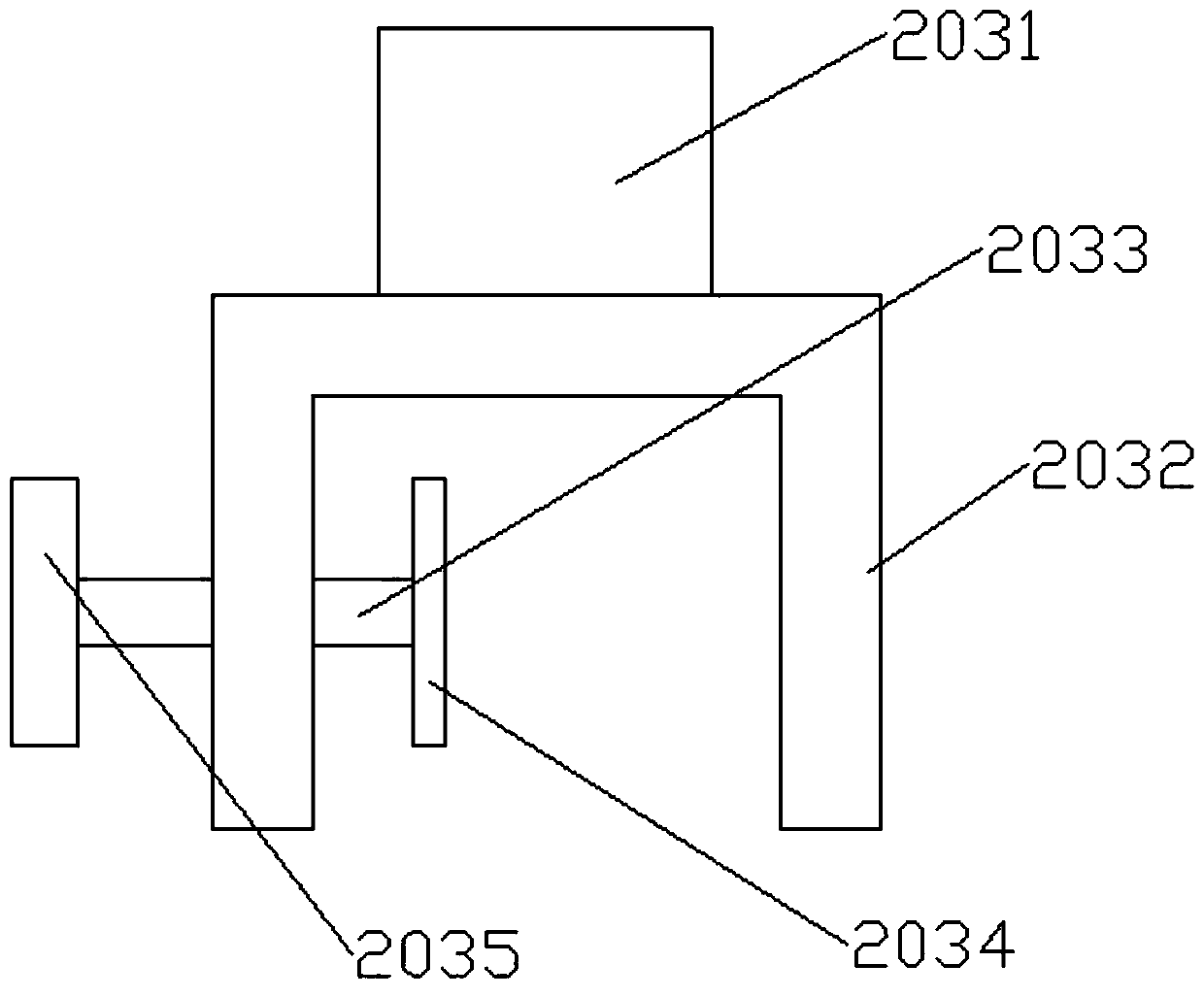

[0039] The fixing assembly 203 includes a connecting block 2031 and a clamping seat 2032, the two ends of the connecting block 2031 are fixedly connected with the sliding seat 202 and the clamping seat 2032 respectively, the clamping seat 2032 is U-shaped, and one of the vertical plates of the clamping seat 2032 A screw 2033 is connected in rotation, and one end of the screw 2033 located in the clamping seat 2032 is fixedly connected with a rubber pad 2034, and one end of the screw 2033 located outside the clamping seat 2032 is fixedly connected with a first knob 2035, and the opening of the upper clamping seat 2032 faces downward , the opening of the lower holding seat 2032 faces upward.

Embodiment 3

[0041] The difference from Example 2 is that it also includes the following:

[0042] The paint spraying pipe 404 comprises a top pipe 4041, an intermediate pipe 4042 and a bottom pipe 4043, and the intermediate pipe 4042 is provided with several, and one side of the top pipe 4041, the middle pipe 4042 and the bottom pipe 4043 is connected with a nozzle 4044 through a pipeline, and the top pipe 4041 and The middle pipe 4042 is cylindrical with both ends open, the bottom of the bottom pipe 4043 is sealed, the circumference of the bottom of the outer wall of the top pipe 4041 is evenly fixed with a set of fixing seats 4045, and the circumference of the top of the outer wall of the bottom pipe 4043 is evenly fixed with a set of fixing seats 4045, the bottom and top of the outer wall of the middle pipe 4042 are uniformly fixed with a group of fixing seats 4045, the bottom surface of the top pipe 4041 and the middle pipe 4042 is provided with an annular sealing groove 4046, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com