U-shaped bending machine for building

A technology for bending machines and construction, applied in the field of bending machines, can solve the problems that steel bars are not practical, difficult to realize, and difficult to bend technology, so as to avoid excessive or insufficient bending, and to achieve good bending effect. simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

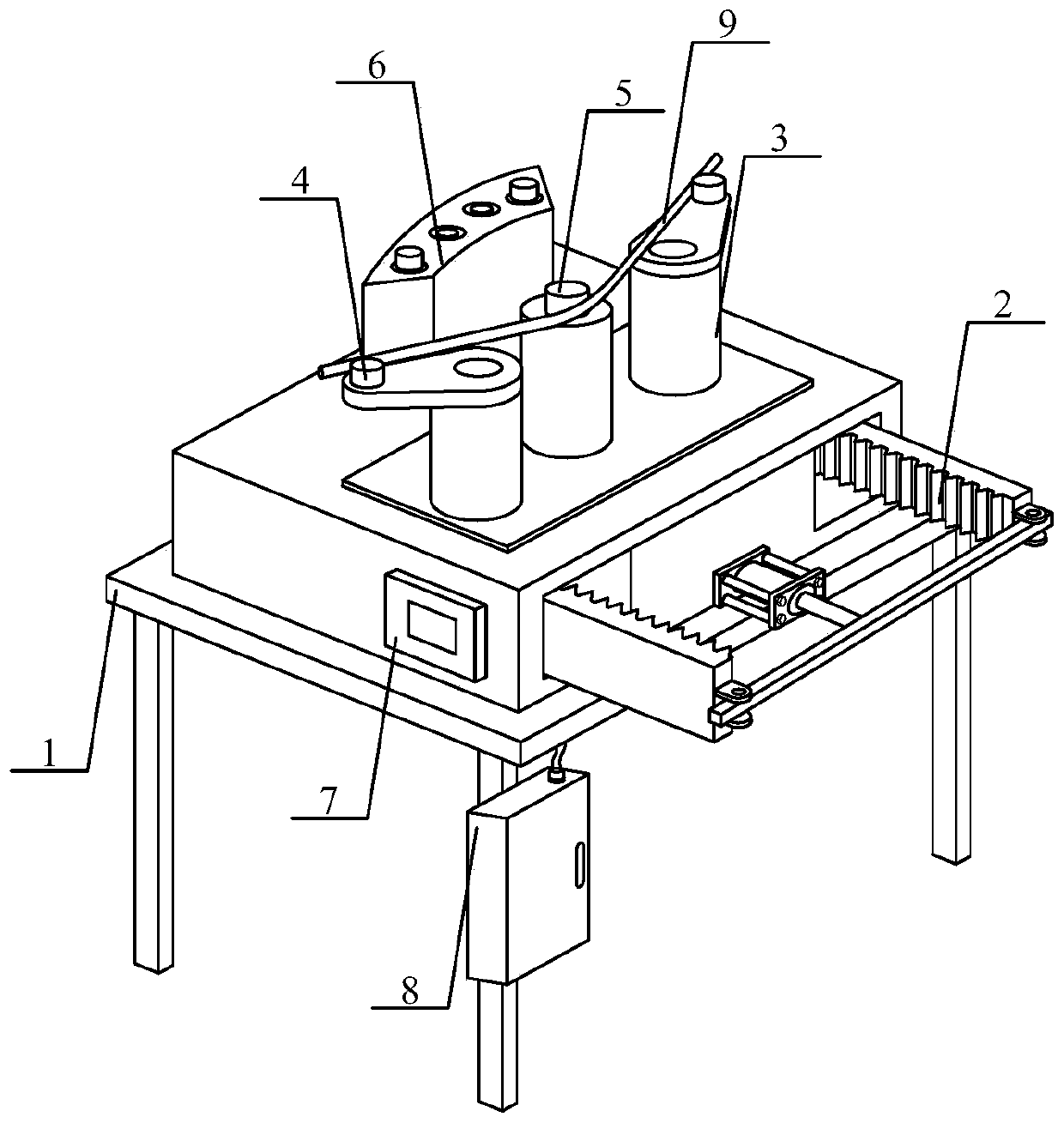

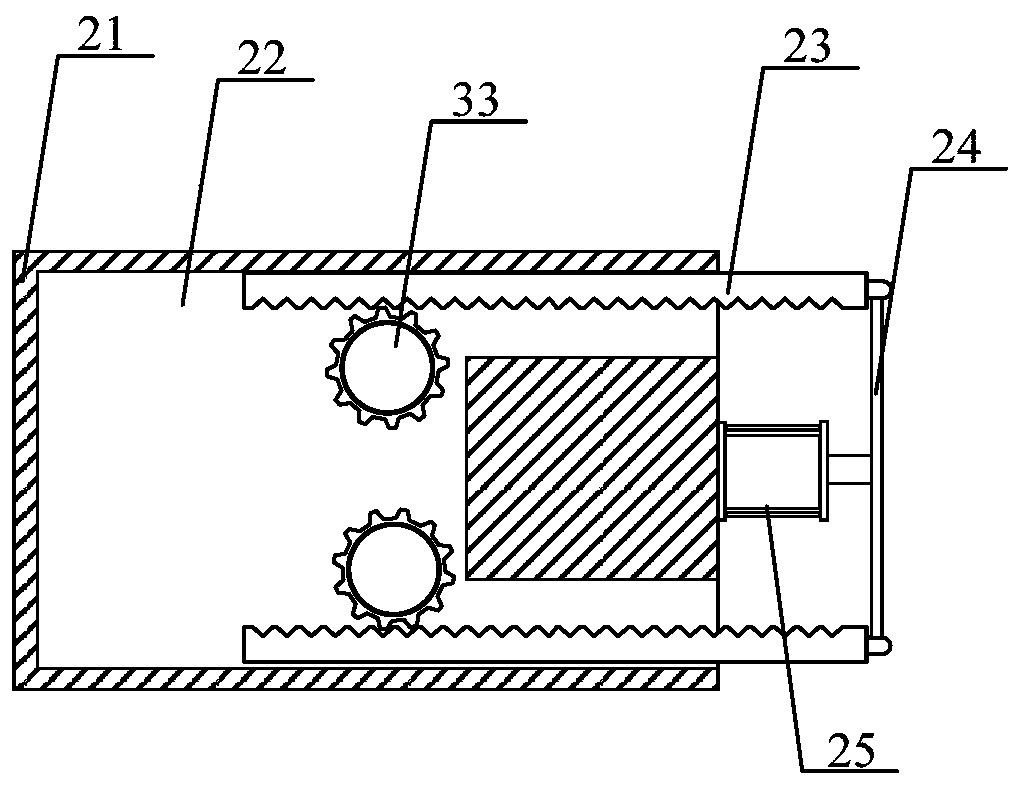

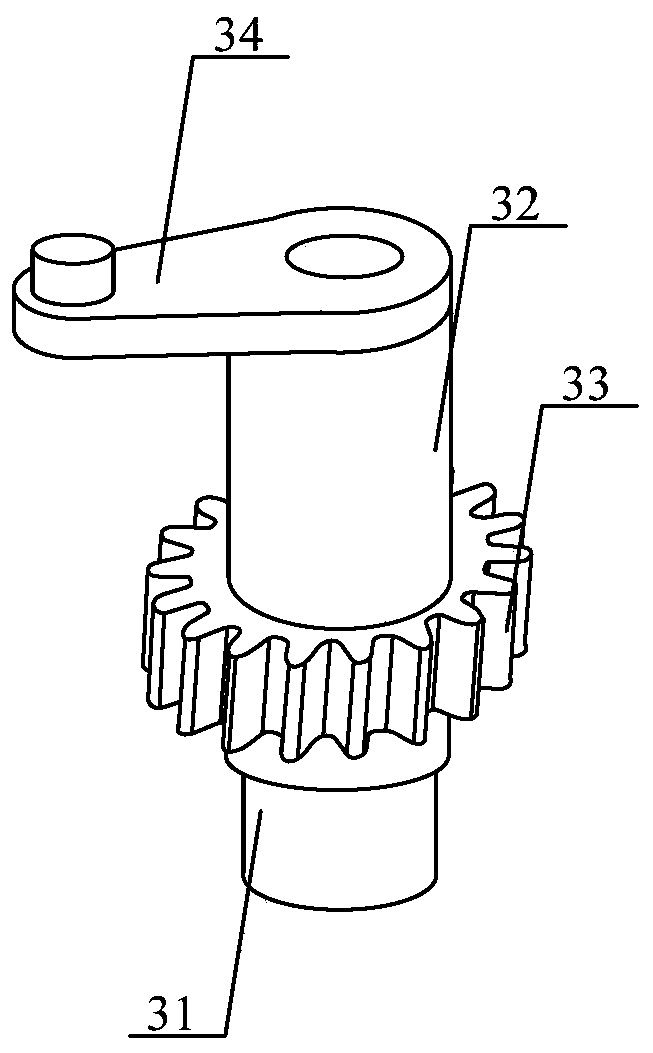

[0027] Such as Figure 1-6 As shown, the present invention provides a technical solution: a U-shaped bending machine for construction, including a frame body, a driving mechanism, a first bending mechanism, a second bending mechanism, a fixing piece, a limit mechanism, and a push cylinder Controller, junction box and steel bars, the frame body is welded by 4 angle irons and a rectangular steel plate, and the angle irons are welded at the four corners of the bottom of the rectangular steel plate; the drive mechanism is installed on the frame body through bolts above; the first bending mechanism and the second bending mechanism are arranged on the driving mechanism, and are detachably connected with the driving mechanism; the fixing member is arranged between the first bending mechanism and the second bending mechanism The fixing part is vertically welded at the middle position of the top of the driving mechanism; the limit mechanism is arranged on the left side of the fixing pa...

Embodiment 2

[0029] A U-shaped bending machine for construction, including a frame body, a driving mechanism, a first bending mechanism, a second bending mechanism, a fixing piece, a limit mechanism, a push cylinder controller, a junction box and a steel bar, the described The frame body is welded by 4 angle irons and a rectangular steel plate, and the angle irons are welded at the four corners of the bottom of the rectangular steel plate; the driving mechanism is installed on the frame body through bolts; the first bending mechanism and The second bending mechanism is arranged on the driving mechanism and is detachably connected with the driving mechanism; the fixing piece is arranged between the first bending mechanism and the second bending mechanism, and the fixing piece is vertically welded on the top of the driving mechanism The middle position; the limit mechanism is arranged on the left side of the fixing part, and the limit mechanism is welded with the top of the fixing part; the p...

Embodiment 3

[0032]A U-shaped bending machine for construction, including a frame body, a driving mechanism, a first bending mechanism, a second bending mechanism, a fixing piece, a limit mechanism, a push cylinder controller, a junction box and a steel bar, the described The frame body is welded by 4 angle irons and a rectangular steel plate, and the angle irons are welded at the four corners of the bottom of the rectangular steel plate; the driving mechanism is installed on the frame body through bolts; the first bending mechanism and The second bending mechanism is arranged on the driving mechanism and is detachably connected with the driving mechanism; the fixing piece is arranged between the first bending mechanism and the second bending mechanism, and the fixing piece is vertically welded on the top of the driving mechanism The middle position; the limit mechanism is arranged on the left side of the fixing part, and the limit mechanism is welded with the top of the fixing part; the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com