Crown block slide wire collector

A sliding line set, crane technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of easy jumping, reduction of sliding vane height, ignition, etc., to avoid inconsistent wear, ensure normal operation, increase The effect of roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

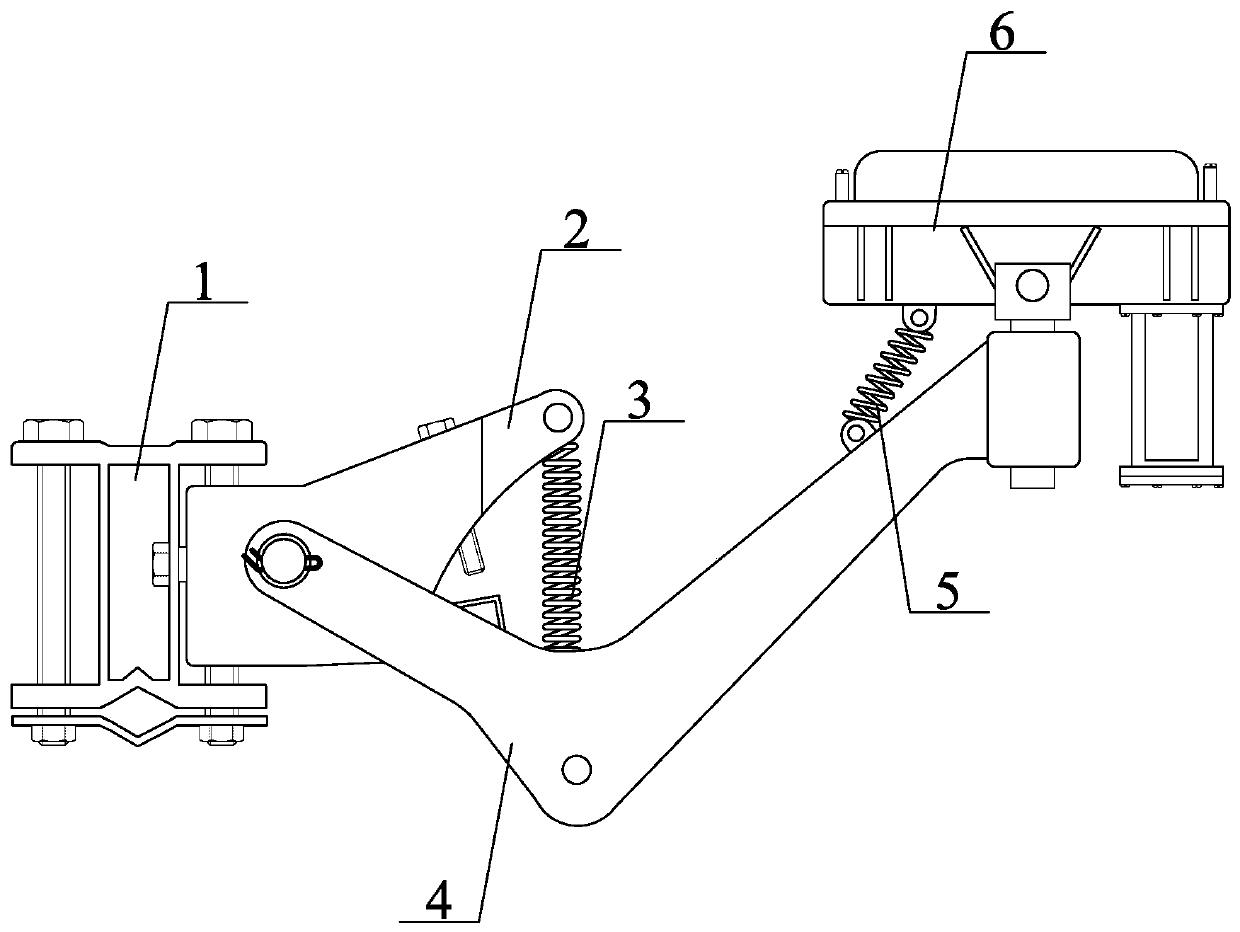

[0027] Such as Figure 1-5 As shown, the present invention provides a technical solution: a sliding wire collector for a crane, including a crane end mounting frame, a swing arm mechanism, a tension spring, a support arm mechanism, an anti-drop spring and a current collector, the The swing arm mechanism is movably connected with the mounting frame at the end of the crane; the two ends of the tension spring are respectively buckled on the first pin shaft and the second pin shaft; the support arm mechanism is connected with the swing arm mechanism through the rotating shaft , the support arm mechanism is connected to the current collector through the anti-off spring; the current collector is plugged into the right end of the support arm mechanism.

Embodiment 2

[0029] A sliding wire collector for a crane, including a crane end mounting frame, a swing arm mechanism, a tension spring, a support arm mechanism, an anti-drop spring and a current collector, and the swing arm mechanism is movable with the crane end mounting frame connection; the two ends of the tension spring are buckled respectively on the first pin shaft and the second pin shaft; The electric device is connected; the current collecting device is plugged into the right end of the support arm mechanism.

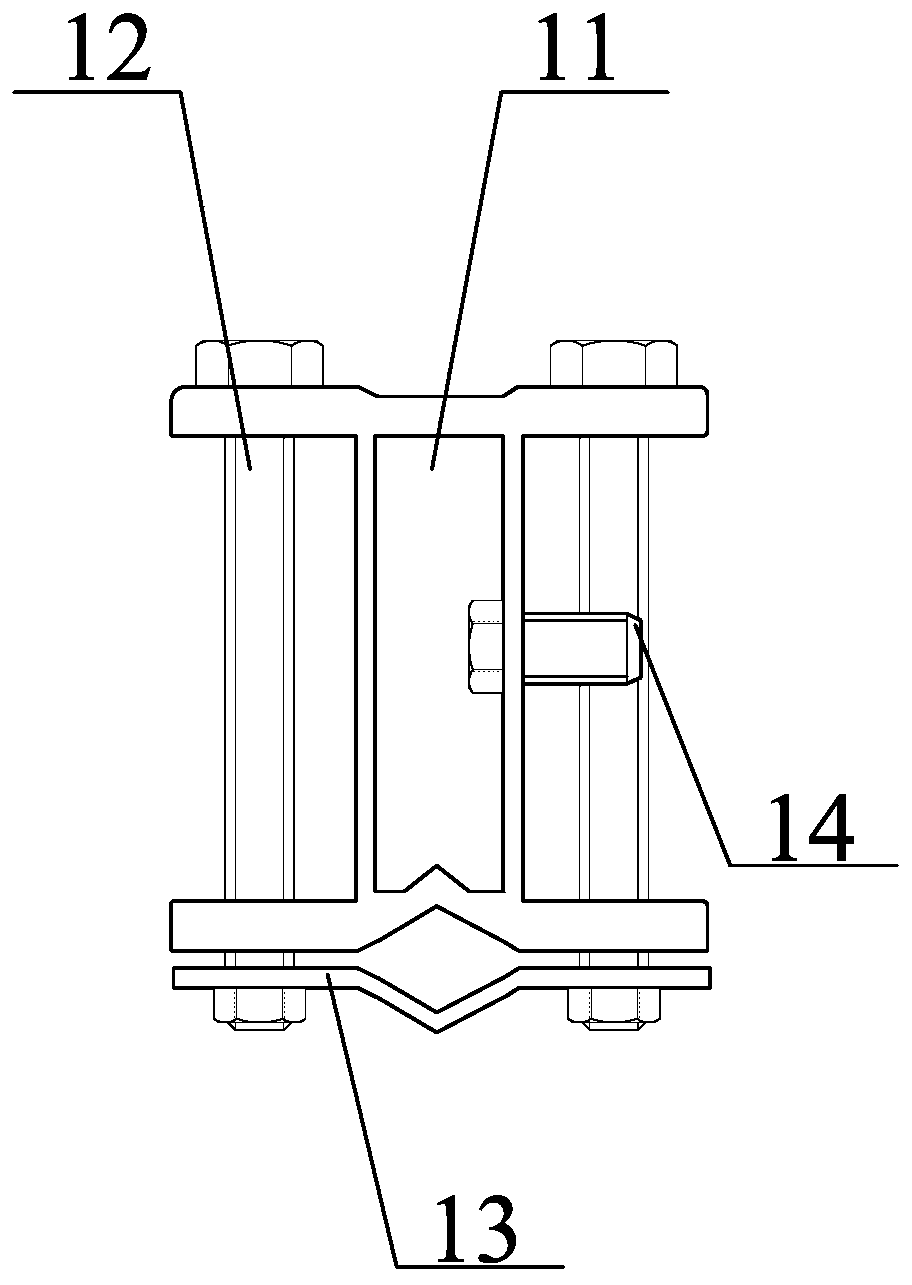

[0030] Preferably, the mounting frame at the end of the crane includes a fixing frame, bolts, cards and fixing bolts, the fixing frame is set in the shape of "I", and bolt holes are opened at the four corners; two bolts are used, Through the fixing frame and the card are fixed by nuts; the middle position of the card in contact with the fixing frame is diamond-shaped; the fixing bolt is threaded with the fixing frame, the bolt passes through the fixing frame and the connec...

Embodiment 3

[0032] A sliding wire collector for a crane, including a crane end mounting frame, a swing arm mechanism, a tension spring, a support arm mechanism, an anti-drop spring and a current collector, and the swing arm mechanism is movable with the crane end mounting frame connection; the two ends of the tension spring are buckled respectively on the first pin shaft and the second pin shaft; The electric device is connected; the current collecting device is plugged into the right end of the support arm mechanism.

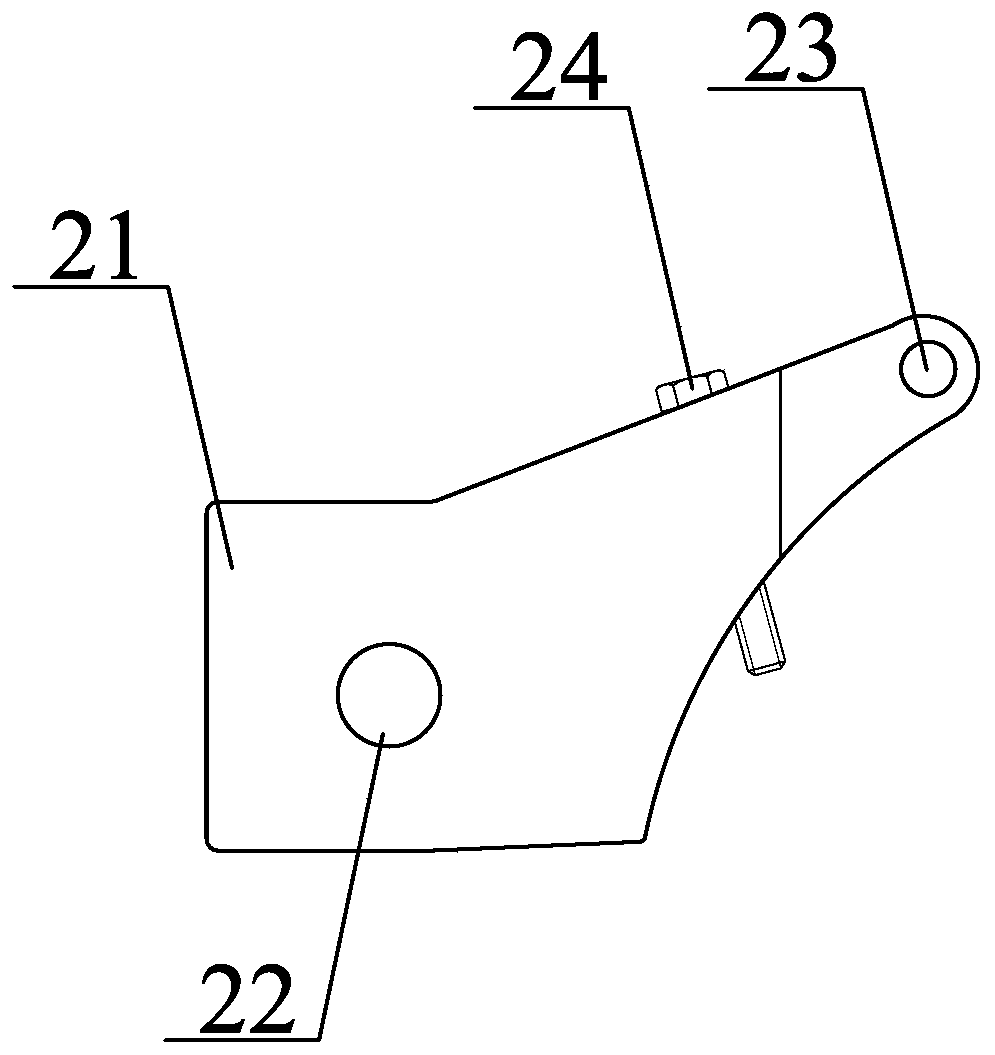

[0033] Preferably, the swing arm mechanism includes a boom, a shaft hole, a first pin shaft and a limit bolt, and the boom is movably connected to the fixed frame through bolts; the shaft hole is opened on the left side of the boom middle position; the first pin shaft is set on the upper right part of the boom; the limit bolt is threadedly connected with the boom, and the first pin shaft tightens the support arm mechanism through the tension spring, giving the support arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com