Engine fuel correction control method

A control method and engine technology, applied in engine control, fuel injection control, machine/engine, etc., can solve problems such as slow learning speed, worsening fuel injection results, and biased correction values, and achieve the effect of accurate learning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] With reference to the accompanying drawings, the specific implementation of the present invention will be further described in detail through the description of the best embodiment.

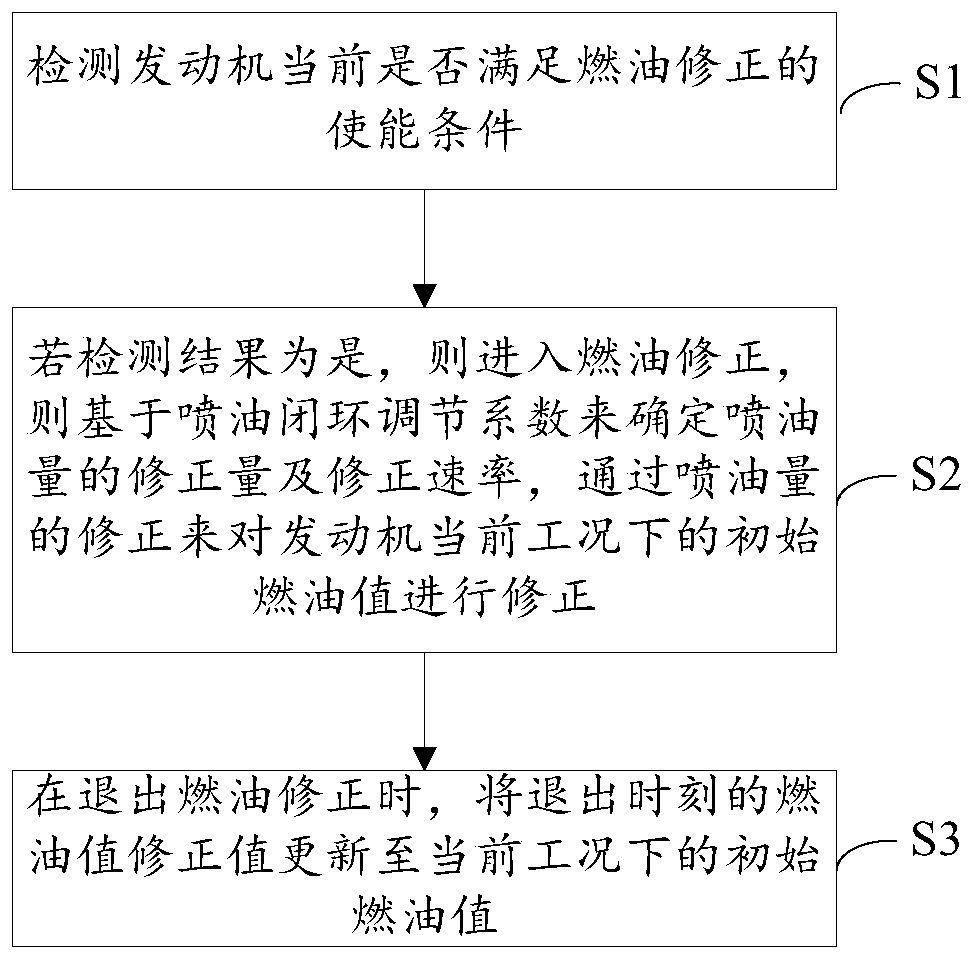

[0028] figure 1 This is a flowchart of a long-term fuel correction control method for an engine provided by an embodiment of the present invention. The method specifically includes the following steps:

[0029] S1. Detect whether the engine currently meets the fuel correction enabling conditions;

[0030] In the embodiment of the present invention, the engine is in a relatively stable operating condition, which is very necessary for accurately learning the deviation of the fuel injection amount. The specific enabling conditions for fuel correction are as follows: the engine cooling water temperature rises above 80 degrees, the intake manifold pressure is above 200hPa, and the air-fuel ratio is in the closed-loop control phase (no rapid acceleration, rapid deceleration, or exhaust system component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com