Hash mapping storage method and system for second flow thickness

A technology of mapping storage and second traffic, which is applied to structured data retrieval, rolling mill control devices, database indexing, etc., can solve the problems of complex calculation process and low efficiency of queue data structure and storage method, and improve data retrieval efficiency and improve Calculation efficiency and the effect of reducing the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

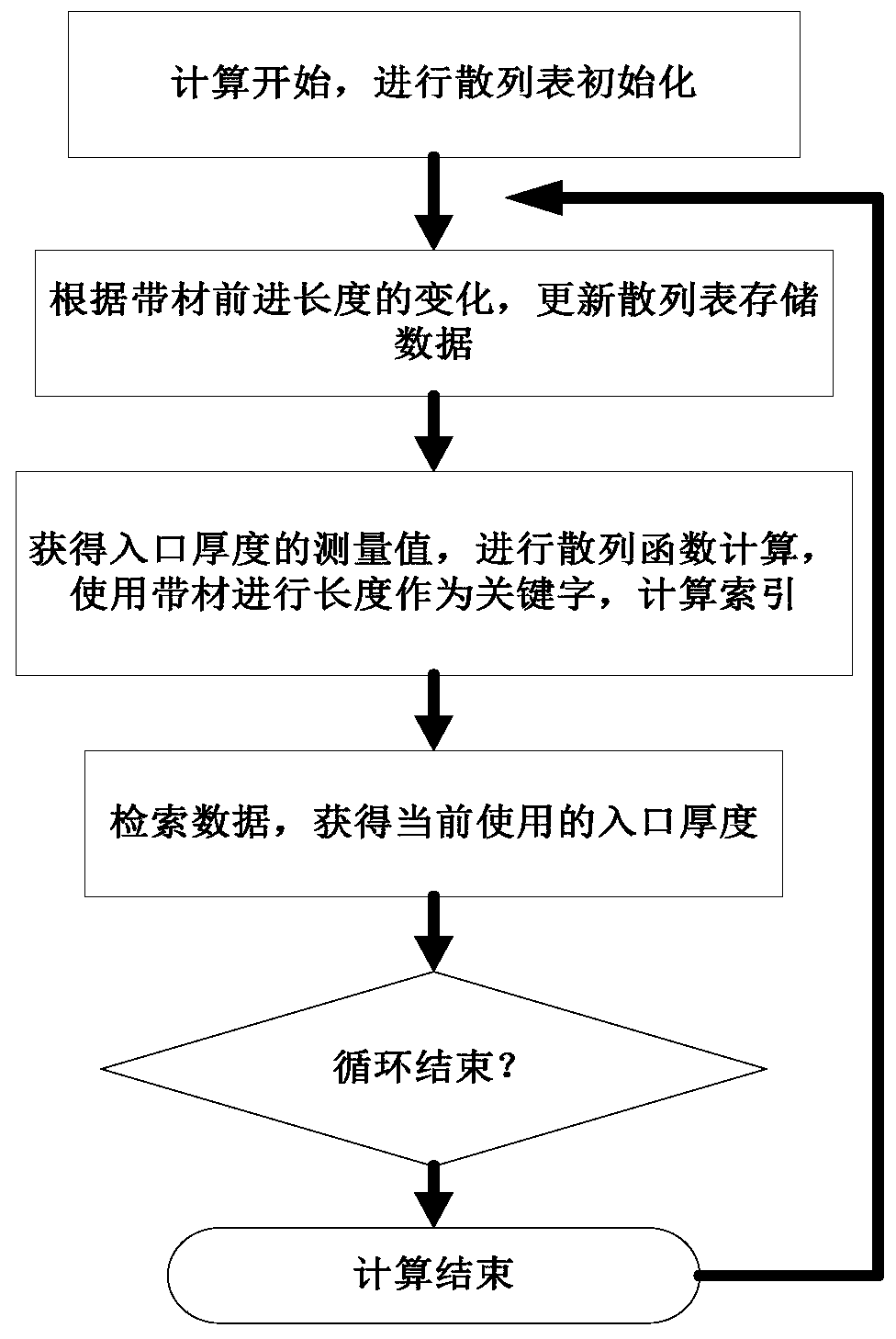

[0044] Such as figure 1 As shown, a hash map storage method of second flow thickness control for metal processing and rolling, including the following steps:

[0045] S1. Initialize the hash table, the entrance thickness measuring device measures the thickness of the strip at the entrance of the roll gap, and stores it in the data structure of the hash table;

[0046] S2. Update the stored data in the hash table according to the change of the advancing length of the strip;

[0047] S3. The entrance thickness measurement device obtains the entrance thickness measurement value H from the roll gap, calculates the index of the new data and inserts it into the hash table;

[0048] S4. Retrieve the data to obtain the current entrance thickness value passing through the roll gap used in the second flow thickness control calculation;

[0049] S5. Repeat S2-S4 until the rolling process of one pass is completed, the second flow controller stops counting, and the cycle ends.

[0050] ...

Embodiment 2

[0065] The second aspect of the present invention discloses a hash map storage system for second flow thickness control: it includes a memory and a processor, the memory includes a hash map storage method program for second flow thickness control; the second flow thickness control When the hash map storage method program is executed by the processor, the following steps are implemented:

[0066] S1. Initialize the hash table, the entrance thickness measuring device measures the thickness of the strip at the entrance of the roll gap, and stores it in the data structure of the hash table;

[0067] S2. Update the stored data in the hash table according to the change of the advancing length of the strip;

[0068] S3. The entrance thickness measurement device obtains the entrance thickness measurement value H from the roll gap, calculates the index of the new data and inserts it into the hash table;

[0069] S4. Retrieve the data to obtain the current entrance thickness value pass...

Embodiment 3

[0072] In this embodiment, the hash map storage method of second flow thickness control is put into practical application, and the computer data length is 32, including the following steps:

[0073] S1. The calculation starts and the hash table is initialized.

[0074] After the calculation starts, a hash table needs to be established and initialized, and the key uses the strip length data. Assume that in a certain rolling pass, the data generated by producing the longest strip is 1000, and the length of the computer data generated by rolling one-third of the coil is 333, and the minimum prime number greater than 333 is 337, and the length of the hash table is taken for 337.

[0075] The distance from the entrance thickness measuring device to the roll gap is given as 27m. Assume that the strip advances at a constant speed, the speed is 1m / s.

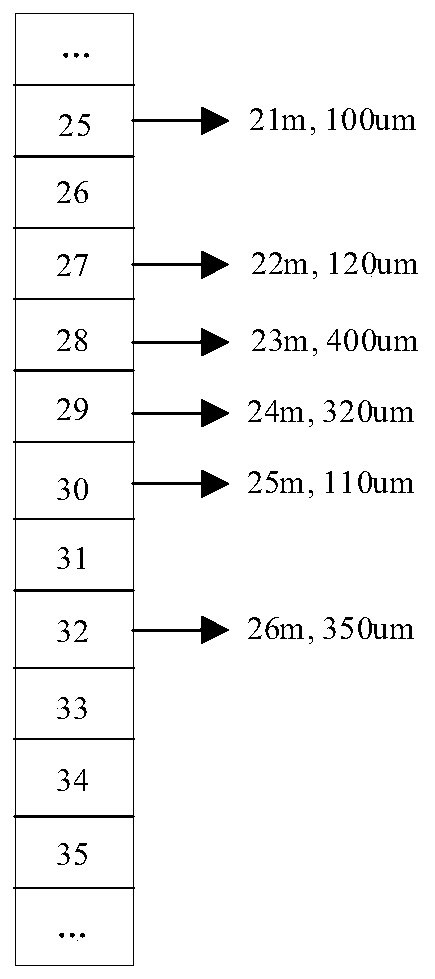

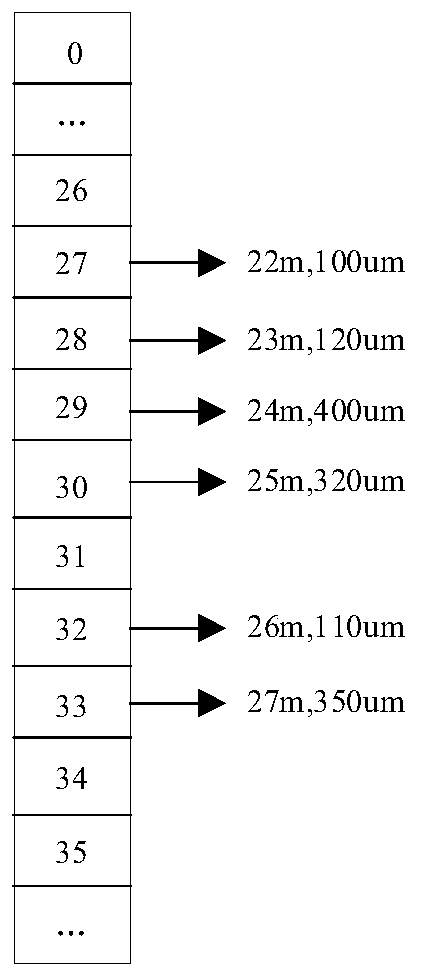

[0076] At a certain N sampling time, the hash table stores data such as figure 2 shown. Among them, the data in the middle colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com