Water spraying dust removal device for green building construction

A technology of dust removal equipment and green building, applied in the directions of using liquid separation agent, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as environmental pollution, no dust removal equipment, etc., and achieve the effect of preventing emission and complete dust removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

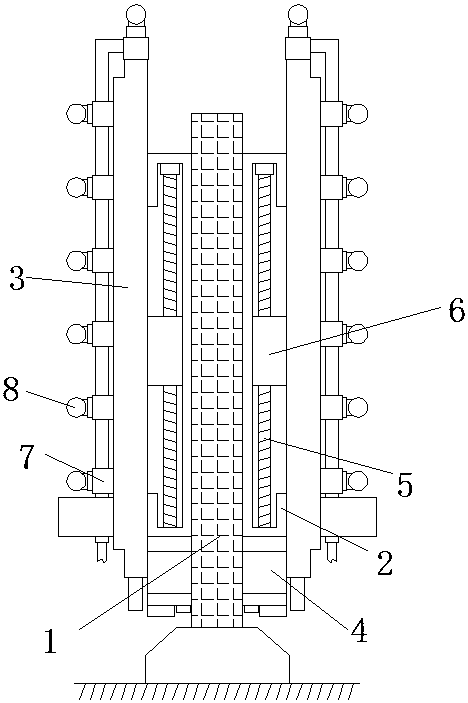

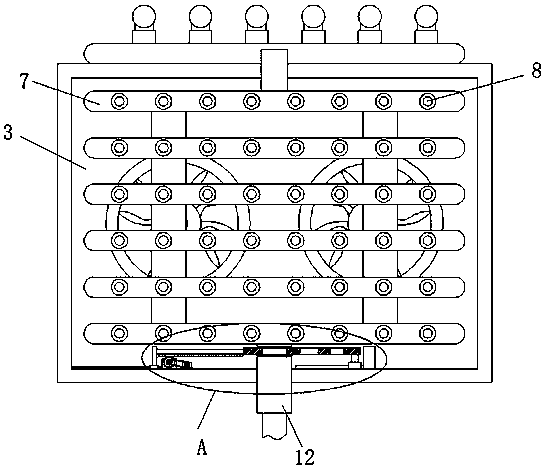

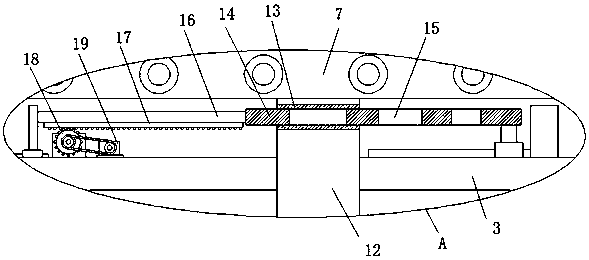

[0024] refer to Figure 1-5 , a water spray dust removal equipment for green building construction, comprising detachable mounting base 2 fixedly installed on both sides of the wall 1, both sides of the mounting base 2 are slidably connected with a dust removal base 3, and the mounting base 2 is fixedly connected with a lifting component, and the lifting component is fixedly connected to one side of the dust removal seat 3, the dust removal seat 3 is provided with a dust suction assembly, the dust removal seat 3 is provided with a water delivery pipe network 7, and the water delivery pipe network 7 is provided with multiple spraying angles Different water spray heads 8 are provided with connected water inlet pipes 12 on the water delivery pipe network 7, and the water inlet pipes 12 are provided with adjustment components for adjusting the flow rate.

[0025] The detachable fixed connection structure of the mounting base 2 and the wall 1 in this embodiment can be a fixed struc...

Embodiment 2

[0027] Further improved on the basis of Embodiment 1: the lifting assembly includes a driving motor 4 fixedly installed at the bottom of the mounting base 2, a sliding groove is opened on one side of the mounting base 2, and the output shaft of the driving motor 4 extends into the sliding groove and is fixed A screw 5 is installed, and one side of the dust removal seat 3 is fixedly equipped with a threaded seat 6, and one end of the threaded seat 6 extends into the sliding groove and is slidably connected with the side wall of the sliding groove, and the screw 5 passes through the threaded seat 6 and is connected to the threaded seat 6 Threaded connection, the screw rod 5 can be driven to rotate by starting the drive motor 4, and the screw rod 5 and the threaded seat 6 are threaded, so the dust removal seat 3 can be raised, and then the water spray coverage area of the water spray head 8 can be increased; dust suction The assembly includes a dust suction cavity 20 set on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com