Smoke dust removal structure, mixer adopting smoke dust removal structure and smoke dust removal method of mixer

A technology of mixing machine and soot, applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., can solve the problems of dust damage to the environment and other problems, and achieve the effects of good smoke removal effect, convenient operation and thorough dust removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

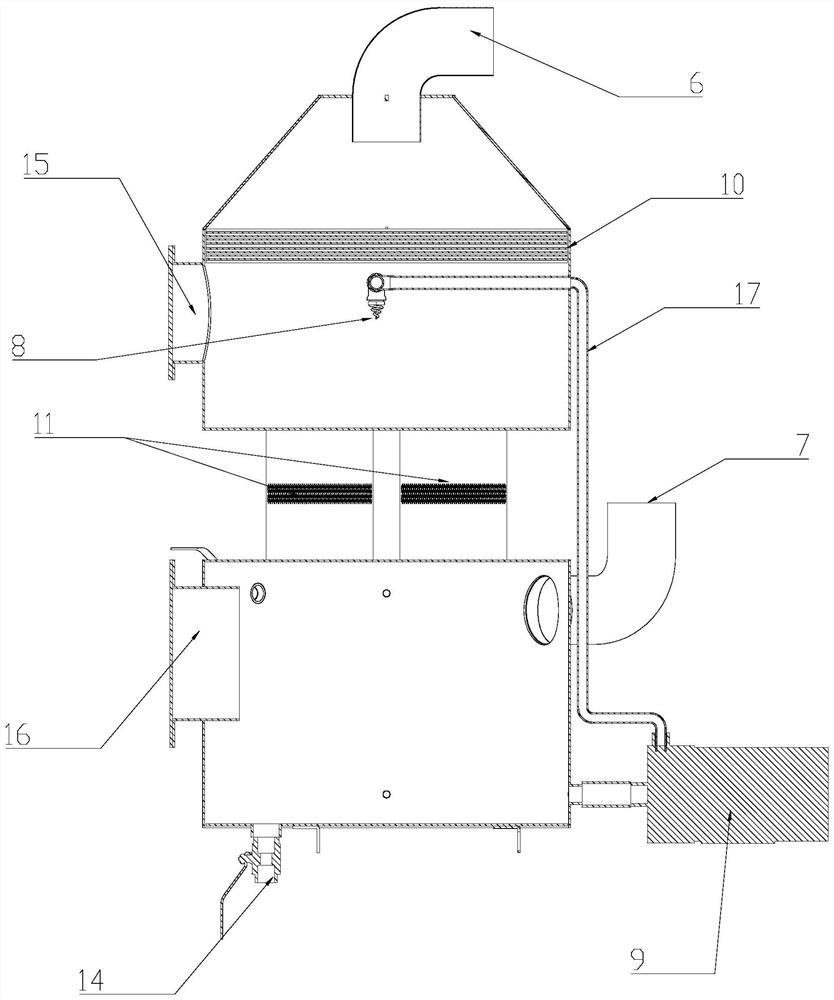

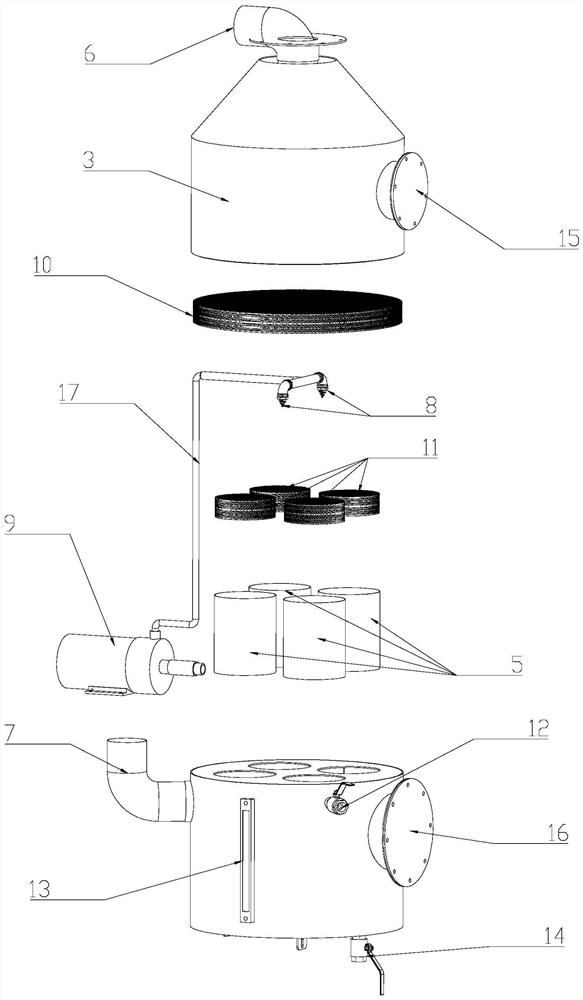

[0035] The technical features of the present invention will be described in further detail below in conjunction with the accompanying drawings so that those skilled in the art can understand.

[0036] The present invention only protects the mechanical structure, and the circuit structure is common knowledge.

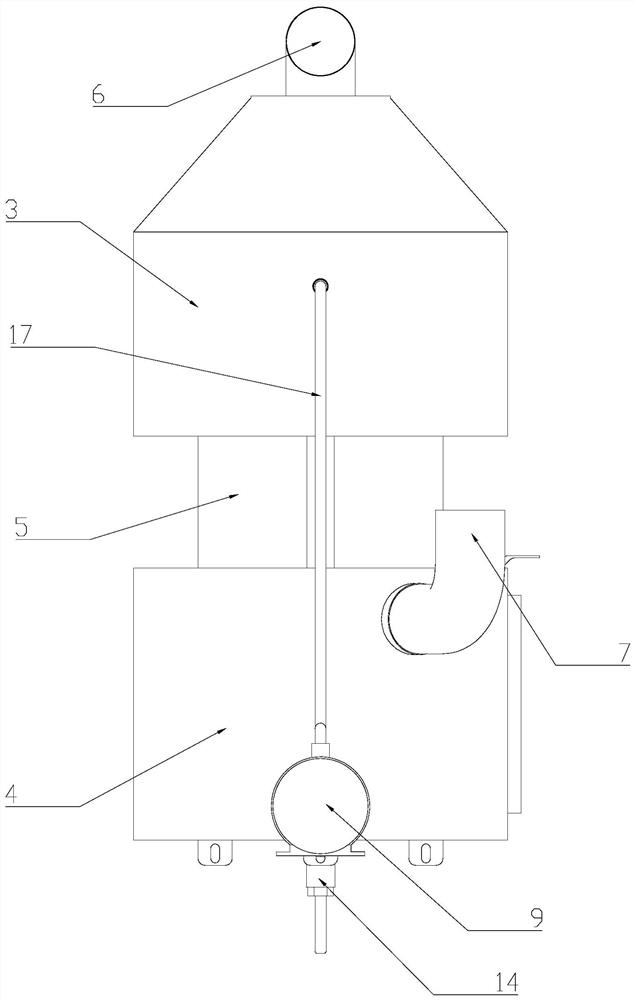

[0037] A smoke and dust removal structure, such as Figure 1 to Figure 9 As shown, it includes: a spray tower 1 for dedusting, on which a smoke input pipe 18 is installed, and the spray tower 1 is connected with a blower fan 2 that promotes the flow of smoke through a smoke outlet pipe 19, The blower 2 is connected with a high-voltage electrostatic smoke removal device 21 through a smoke inlet pipe 27 for further smoke removal after dust removal.

[0038] Specifically, the spray tower 1 includes an upper barrel 3 for water spraying and dust removal and a lower barrel 4 for water storage. The top of the upper barrel 3 is provided with an air outlet 6 connected to the fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com