Two-stage sleeved rotary wet type dust removal gas washer

A wet dust removal and gas washing technology, applied in the field of gas scrubbers, can solve the problems of lack of wet dust removal and gas scrubbers, the purification effect needs to be improved, and achieve the effect of thorough purification and high wind pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

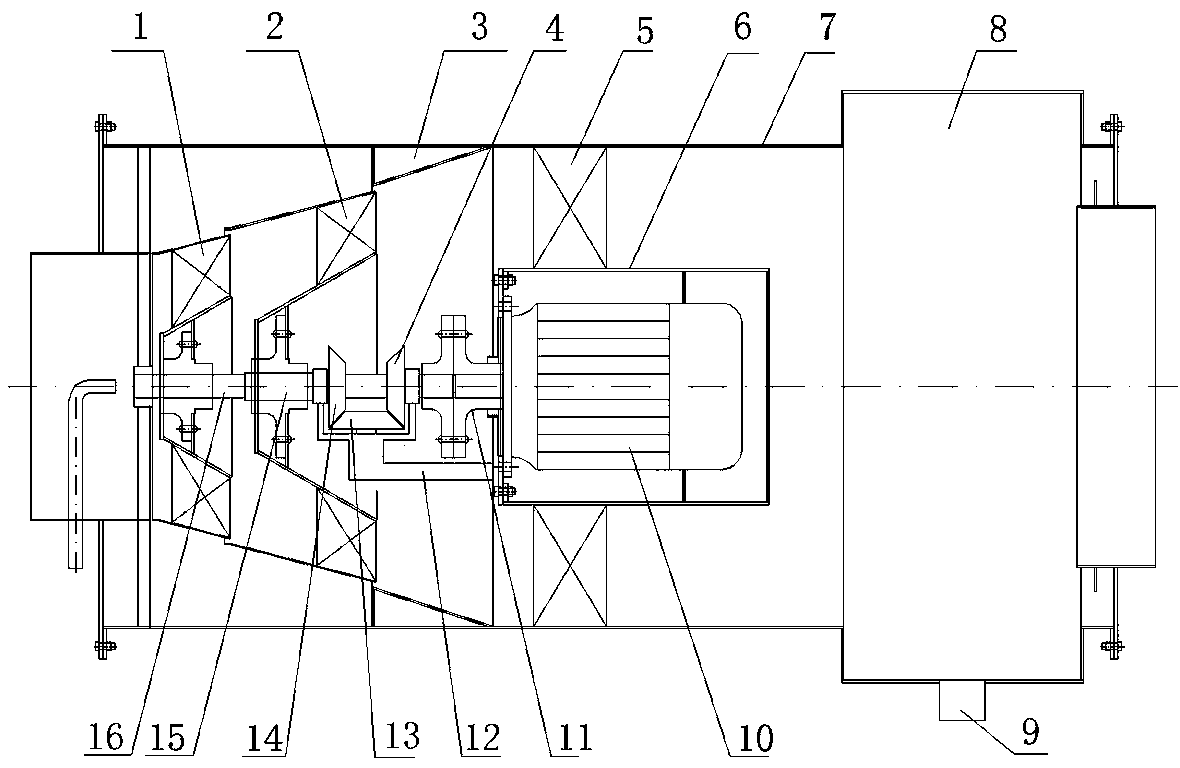

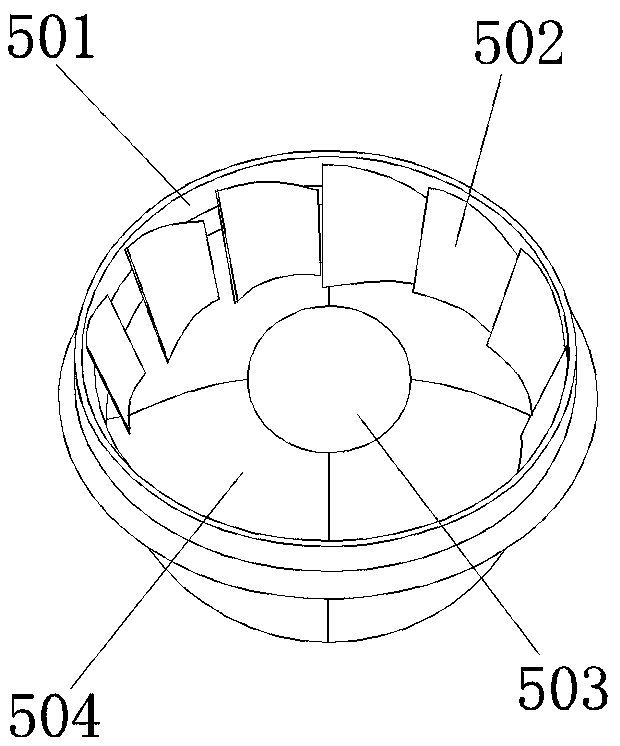

[0021] A two-stage whirling type dust-removing and scrubbing machine includes a casing 7, a motor is fixed in the casing 7, and a first impeller 1 and a second impeller 2 driven by the motor. The first impeller 1 and the second impeller The direction of rotation of the impeller 2 is opposite and the flow is directed towards the air outlet of the casing, such as figure 1 As shown, both the first impeller 1 and the second impeller 2 have the air inlet facing forward and the air outlet facing rearward. It also includes a drive shaft 16, a sleeve 15, a bevel gear A14, a bevel gear B4, a bevel gear C13, and a bevel gear support frame 12. The rear end of the drive shaft 16 is connected to the output shaft of the motor through a coupling 11, and the drive shaft The front end of 16 can be rotatably fixed in the housing through a bearing seat fixed in the housing by welding, the bevel gear A14 is welded and fixed to the rear end of the sleeve 15, and the sleeve 15 is rotatably fixed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com