Reverse-blowing type cloth bag multistage dedusting equipment

A kind of dust removal equipment and back-blowing technology, which is applied to the separation of dispersed particles, chemical instruments and methods, and the filtration of dispersed particles. good effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

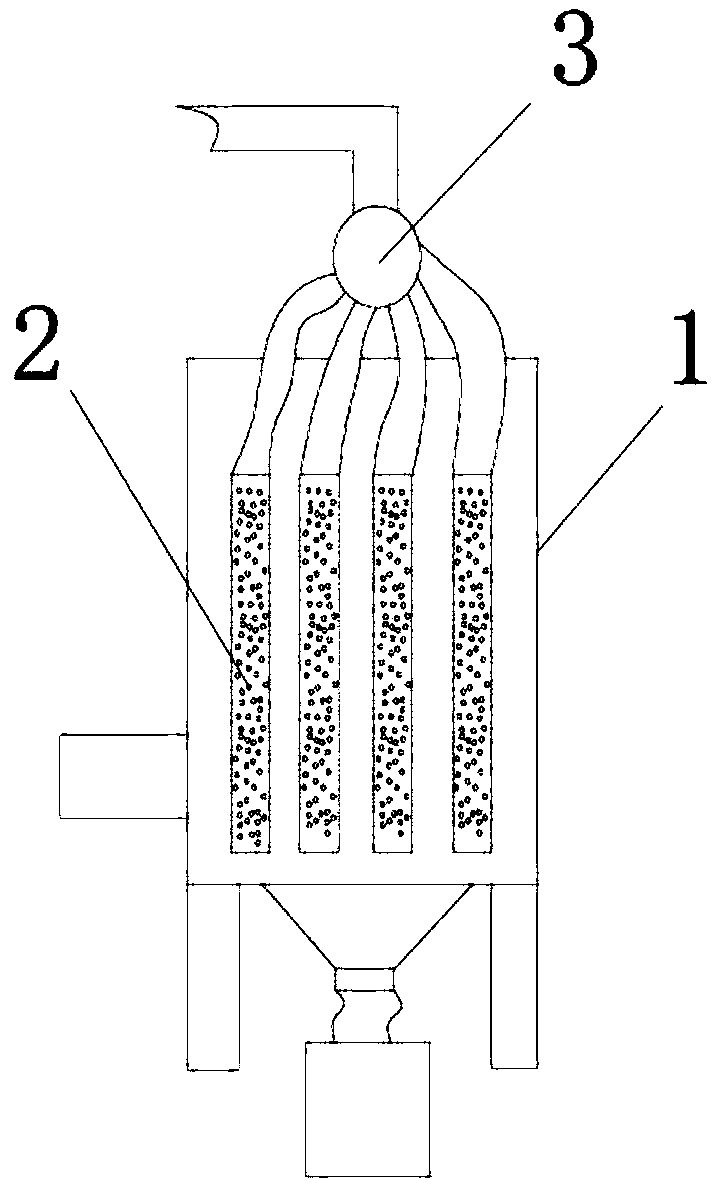

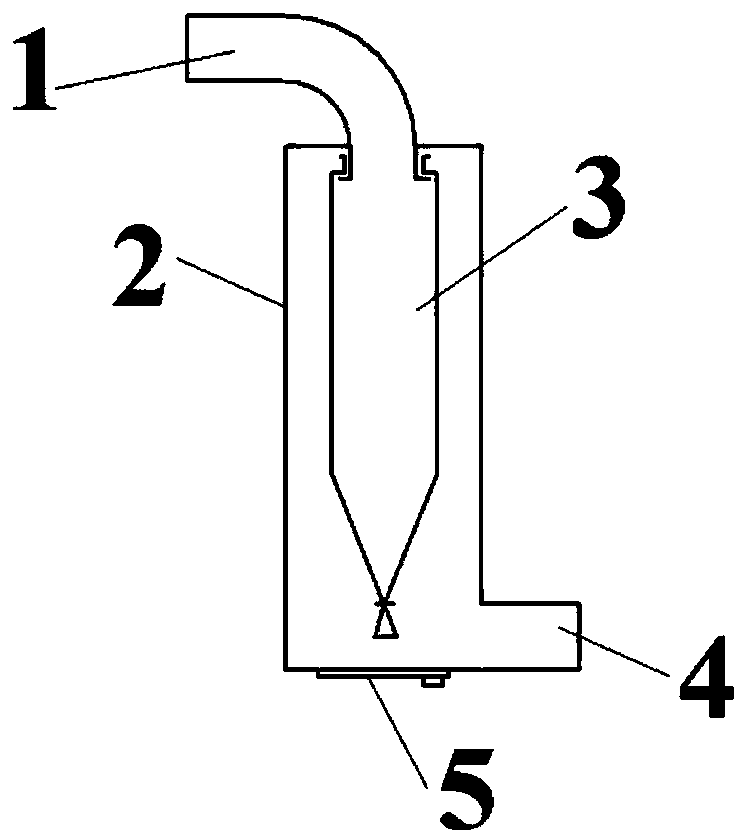

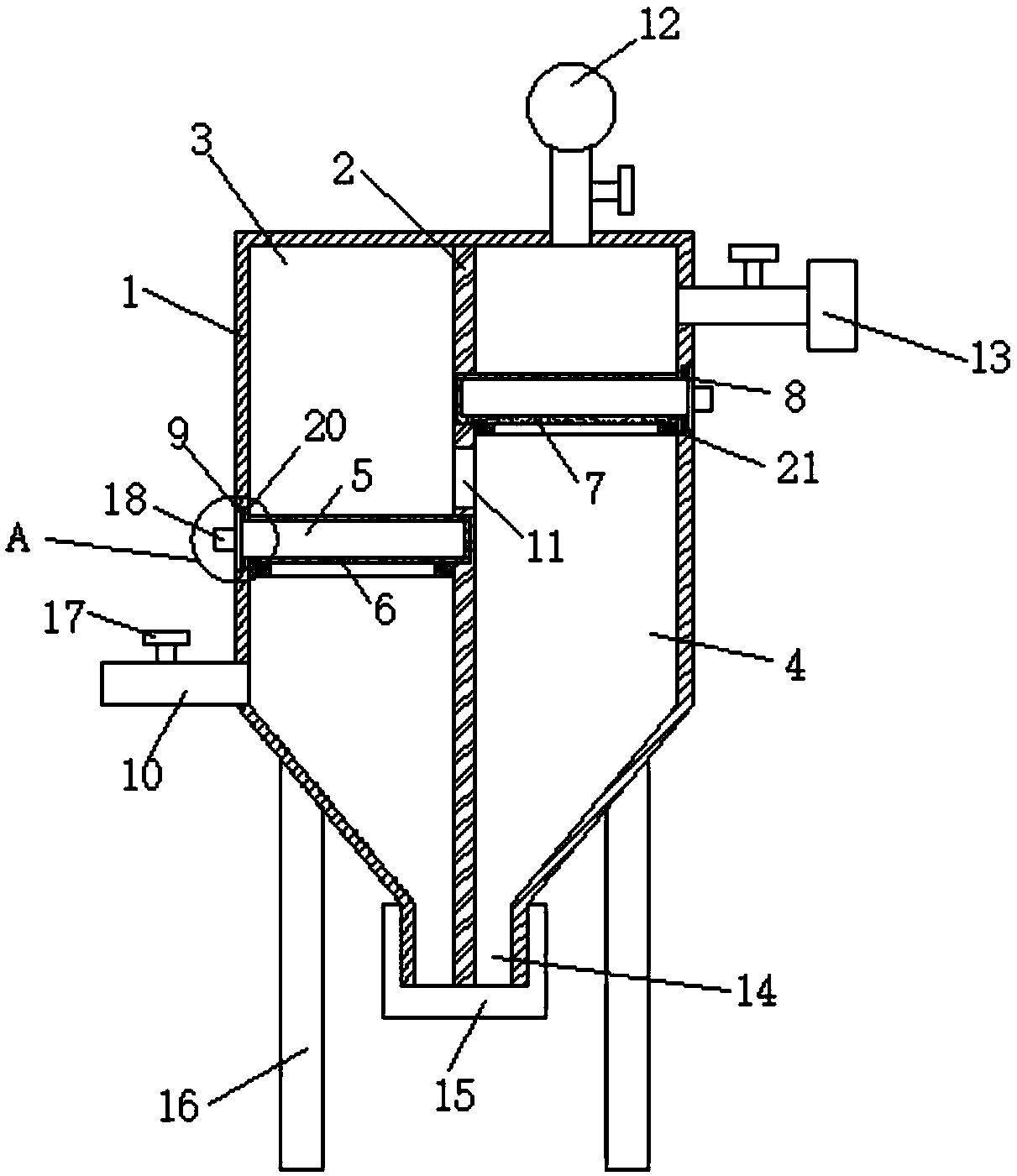

[0041] see Figure 3-6 , a kind of reverse blowing bag multi-stage dedusting equipment, comprising an air intake box 1, a partition 2, a first clean air box 3 and a second clean air box 4, the inside of the air intake box 1 passes through the partition 2 The gas box 1 is divided into a first clean gas box 3 and a second clean gas box 4, and the inner walls of the first clean gas box 3 and the second clean gas box 4 are welded with a convex edge 21, and the convex edge 21 A socket frame 5 is plugged into the top surface, the surface of the socket frame 5 is respectively socketed with a first cloth bag 6 and a second cloth bag 7, and the end of the socket frame 5 is welded with a fixing plate 8. The width of the fixed plate 8 is greater than the width of the sleeve frame 5, the inner side of the fixed plate 8 is pasted with a first magnetic sealing strip 9, one side of the first clean air box 3 is equipped with an intake pipe 10, and the partition The inside of the plate 2 is l...

Embodiment 2

[0050] A reverse blowing bag multi-stage dust removal equipment, including an air intake box 1, a partition 2, a first clean air box 3 and a second clean air box 4, and the inside of the air intake box 1 passes the air intake through the partition 2 The box 1 is divided into a first clean gas box 3 and a second clean gas box 4, the inner walls of the first clean gas box 3 and the second clean gas box 4 are welded with a convex edge 21, and the top of the convex edge 21 A socket frame 5 is plugged on the surface, and the surface of the socket frame 5 is respectively socketed with a first cloth bag 6 and a second cloth bag 7. The end of the socket frame 5 is welded with a fixing plate 8, and the fixed The inner side of the plate 8 is pasted with a first magnetic sealing strip 9, and an air intake pipe 10 is installed on one side of the first clean air box 3, and a vent hole 11 is opened inside the partition plate 2 between the sleeve frames 5 , one side of the second clean air b...

Embodiment 3

[0062] A reverse blowing bag multi-stage dust removal equipment, including an air intake box 1, a partition 2, a first clean air box 3 and a second clean air box 4, and the inside of the air intake box 1 passes the air intake through the partition 2 The box 1 is divided into a first clean gas box 3 and a second clean gas box 4, the inner walls of the first clean gas box 3 and the second clean gas box 4 are welded with a convex edge 21, and the top of the convex edge 21 A socket frame 5 is plugged on the surface, and the surface of the socket frame 5 is respectively socketed with a first cloth bag 6 and a second cloth bag 7. The end of the socket frame 5 is welded with a fixing plate 8, and the fixed The width of the plate 8 is greater than the width of the sleeve frame 5, the inner side of the fixed plate 8 is pasted with a first magnetic sealing strip 9, one side of the first clean air box 3 is equipped with an intake pipe 10, and the partition plate The inside of 2 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com