Rice brushing machine for flexibly removing rice bran

A rice brushing machine and rice bran technology, which is applied in the fields of grain pod removal, grain germ removal, and grain processing, can solve the problems of rice nutrient loss and waste, prevent excessive polishing of brown rice, reduce the rate of broken rice, and reduce growth. broken effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

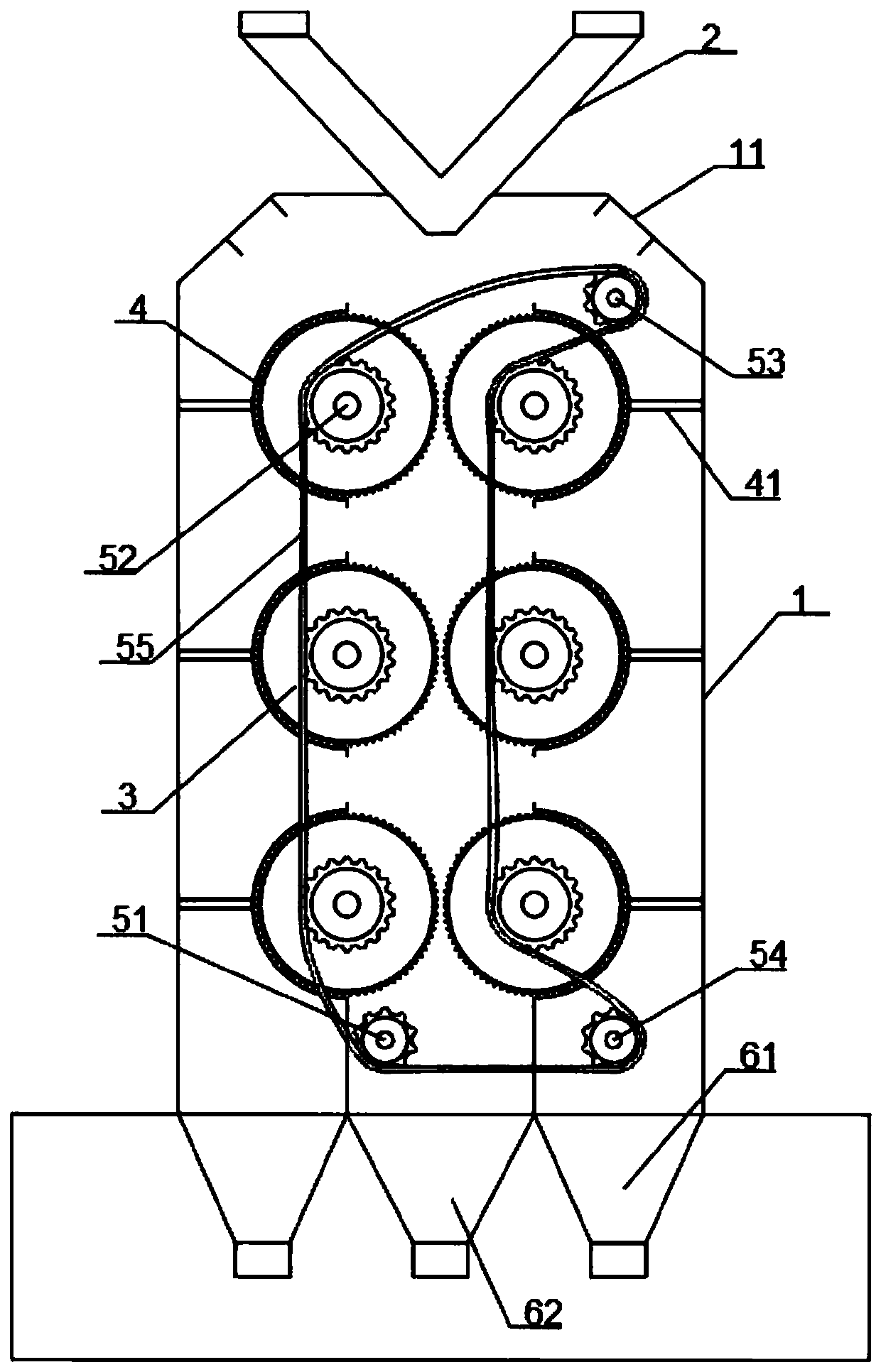

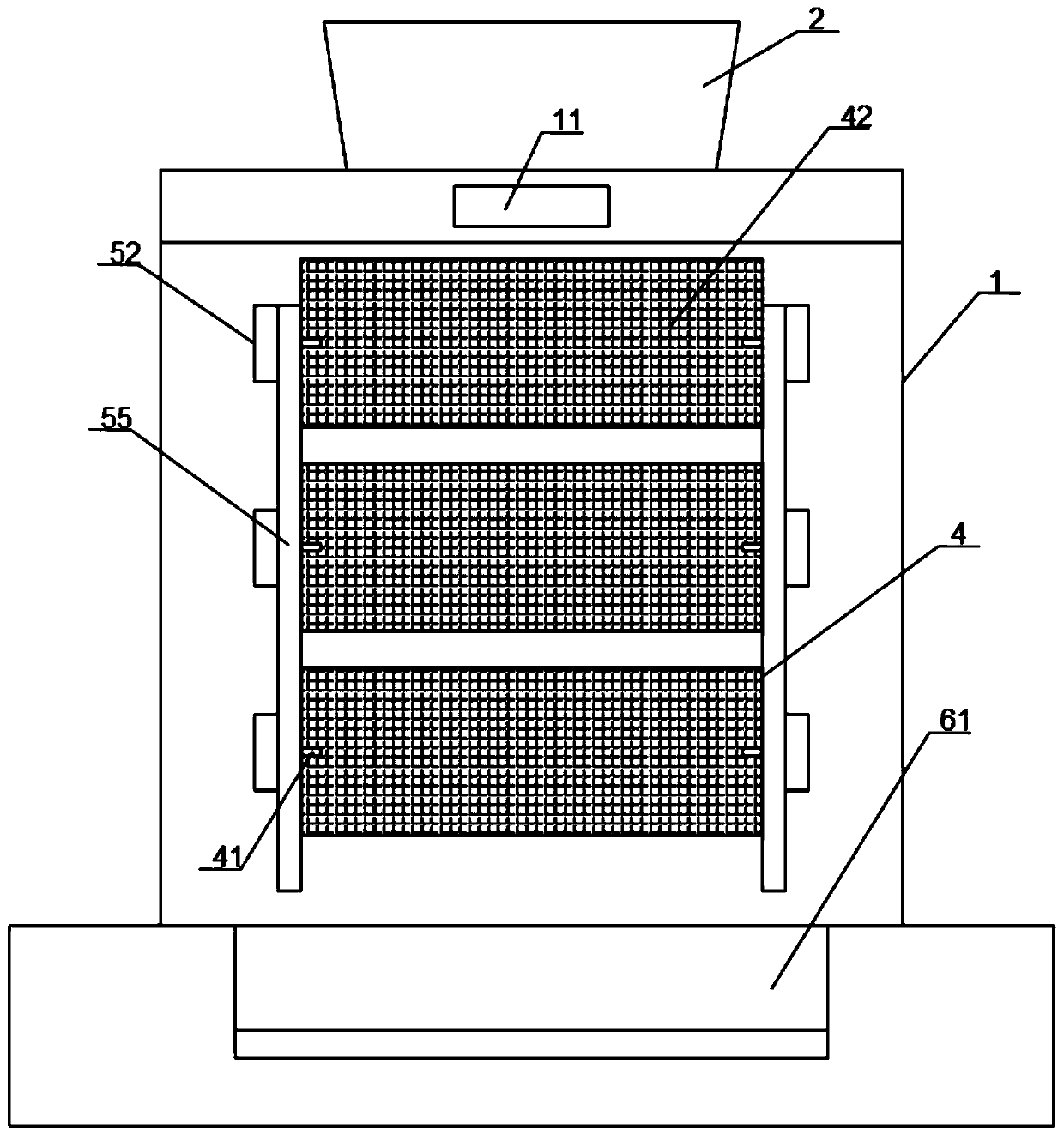

[0026] see Figure 1 to Figure 2 , the present invention provides a rice brushing machine for flexibly removing rice bran, comprising a chassis 1, a hopper 2 arranged on the chassis 1, and a brush roller 3, which includes an axially rotating roller and a brush covering the outer periphery of the roller The brush rollers 3 are arranged side by side in pairs, and the brushes on the two brush rollers 3 arranged side by side are attached to each other; multiple groups of brush rollers 3 arranged side by side are arranged longitudinally and parallel in the cabinet 1; the rice bran powder sieve 4, It is socketed on the outer periphery of the brush roller 3, and the two ends of the rice bran powder sieve 4 are fixedly connected on the inner wall of the cabinet 1 through the connecting rod 41; the transmission wheel set includes a driving wheel 51, a driven wheel 52, a steering wheel 53 and Tensioning pulley 54 also comprises the transmission belt 55 that is closed and tensioned on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com