Production system and assembling method for core part of smoke alarm

A smoke alarm, the core part of the technology, used in fire alarms, assembly machines, metal processing equipment and other directions that rely on smoke/gas effects, can solve problems such as low production efficiency, and achieve improved efficiency, uniform speed, and top cover. location-accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

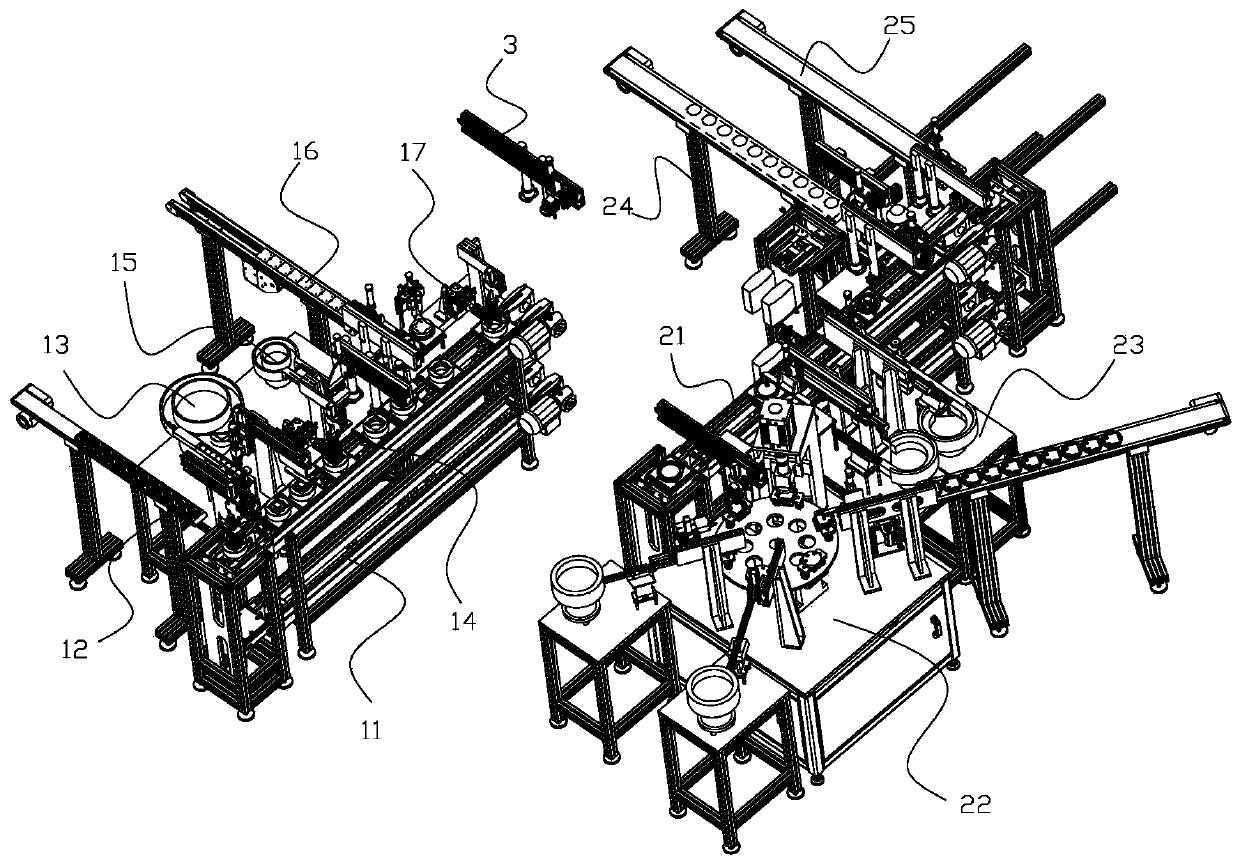

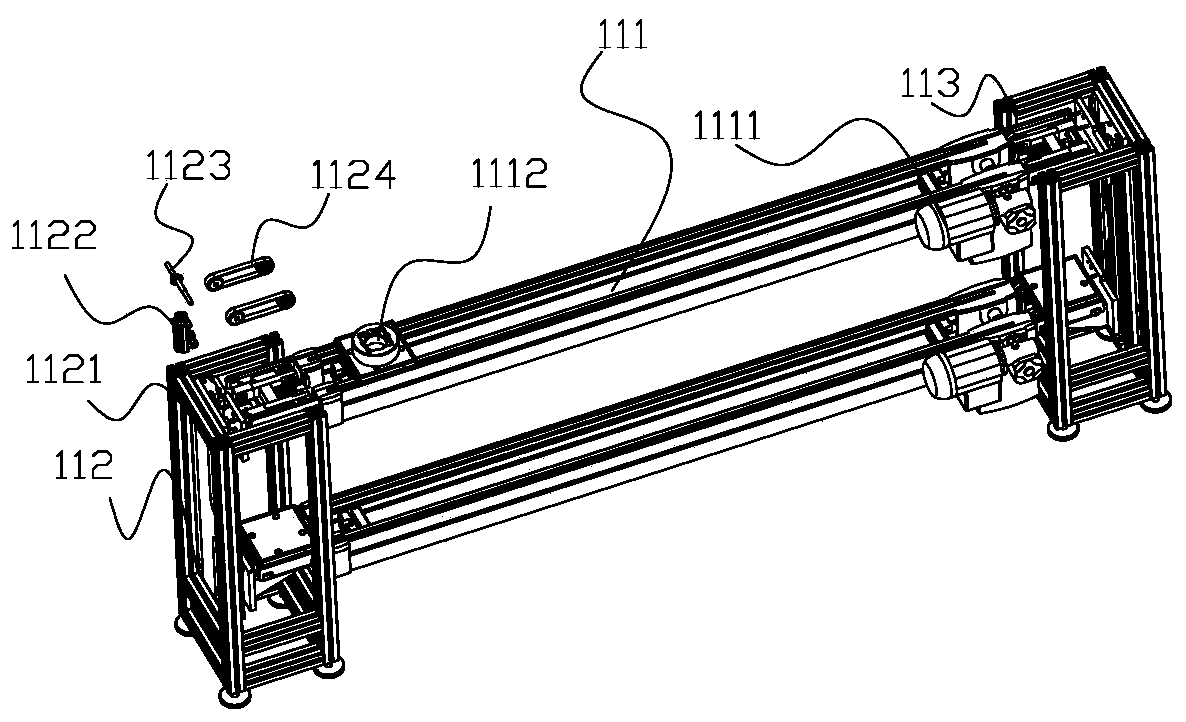

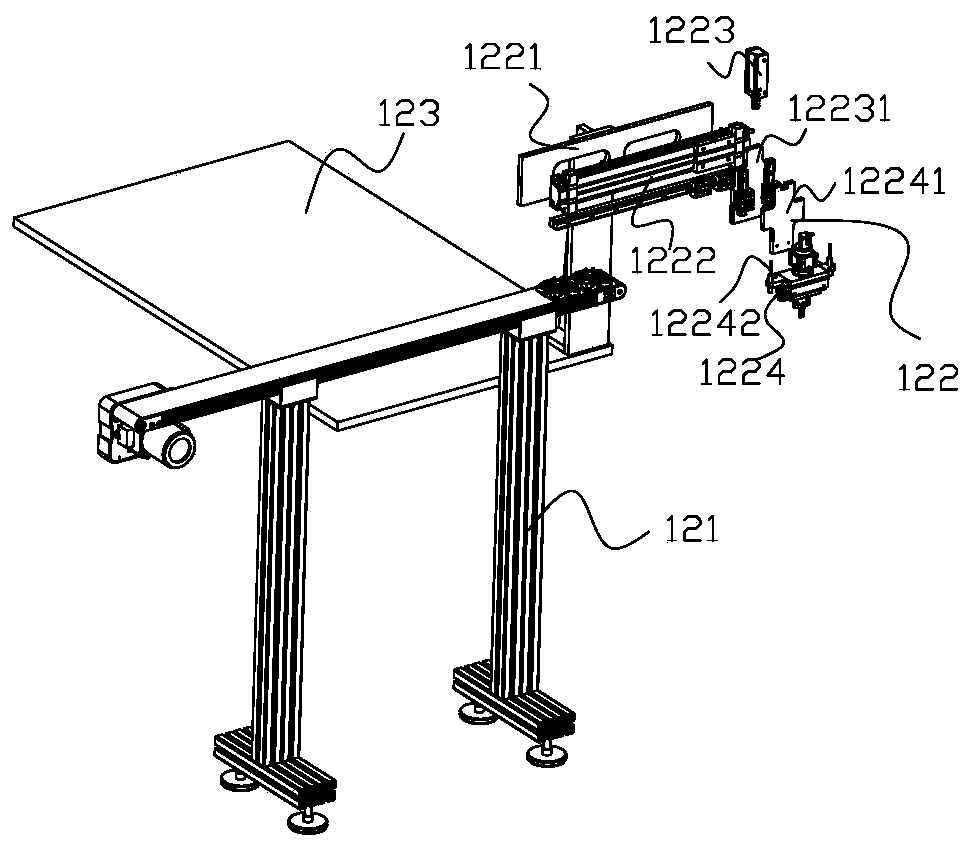

[0040] like figure 1 As shown, a smoke alarm production system includes the production system 1 of the core part of the smoke alarm and the production system 2 of the casing. The production system 1 of the core part of the smoke alarm is used to assemble the core part of the smoke alarm. The core part of the smoke alarm includes the outer shell, the labyrinth, the light guide column and the circuit board. The production system 1 of the core part of the smoke alarm includes the first conveyor Equipment 11 , outer casing feeding device 12 , labyrinth feeding device 13 , first turning device 14 , light guide column feeding device 15 , circuit board feeding device 16 and second turning device 17 . The outer casing feeding device 12 , the labyrinth feeding device 13 , the first turning device 14 , the light guide column feeding device 15 , the circuit board feeding device 16 and the second turning device 17 are sequentially connected to the first conveying device 11 . The shell pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com