Synchronous drive type stern tube bearing dismounting device

A bearing dismounting device and synchronous driving technology, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of surface wear of the stern shaft hole and the inability to ensure the integrity of the bearing, and achieve the effects of convenient use, ingenious structural design and ingenious structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

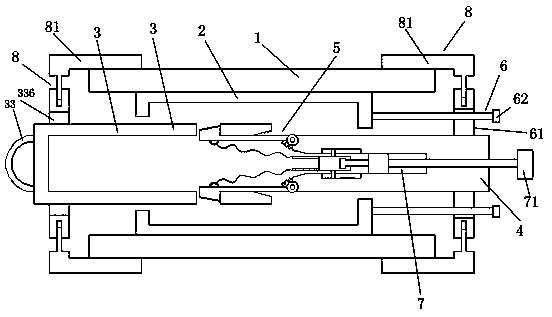

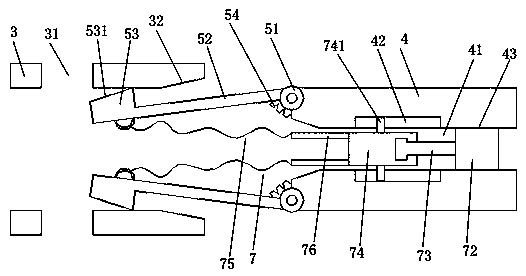

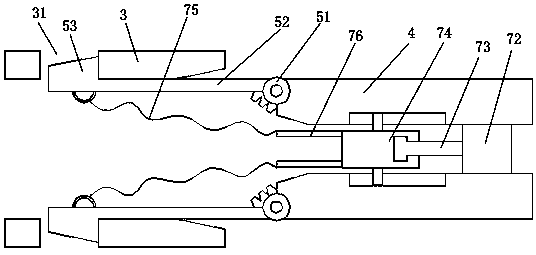

[0021] Such as Figures 1 to 5 As shown, a synchronously driven stern tube bearing removal device includes a stern tube 1, a bearing 2, a pull ring sleeve 3, a plug post 4, a buckle mechanism 5, a limit mechanism 6, and a synchronous clamping mechanism 8; The bearing 2 described above is installed inside the stern tube 1; the inner end of the insert ring sleeve 3 is inserted into the bearing 2 from one end of the bearing 2; the inner end of the insert post 4 is inserted into the bearing 2 from the other end of the bearing 2 Inside; the upper and lower sides of the inner end of the pull ring sleeve 3 are respectively provided with a buckle groove 31; the buckle mechanism 5 includes a buckle block 53, a buckle rod 52, a rotating shaft 51, and an elastic body 54; A rotating shaft 51 is respectively installed on the upper and lower sides of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com