A method for robot to return to initial position at any position at any position

A technology of initial position and arbitrary position, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as low equipment efficiency and manual error-prone, and achieve the effect of avoiding manual operation errors and ensuring portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for a robot to return to an initial position at any position at any position, comprising:

[0031] 1. Planning key points and paths:

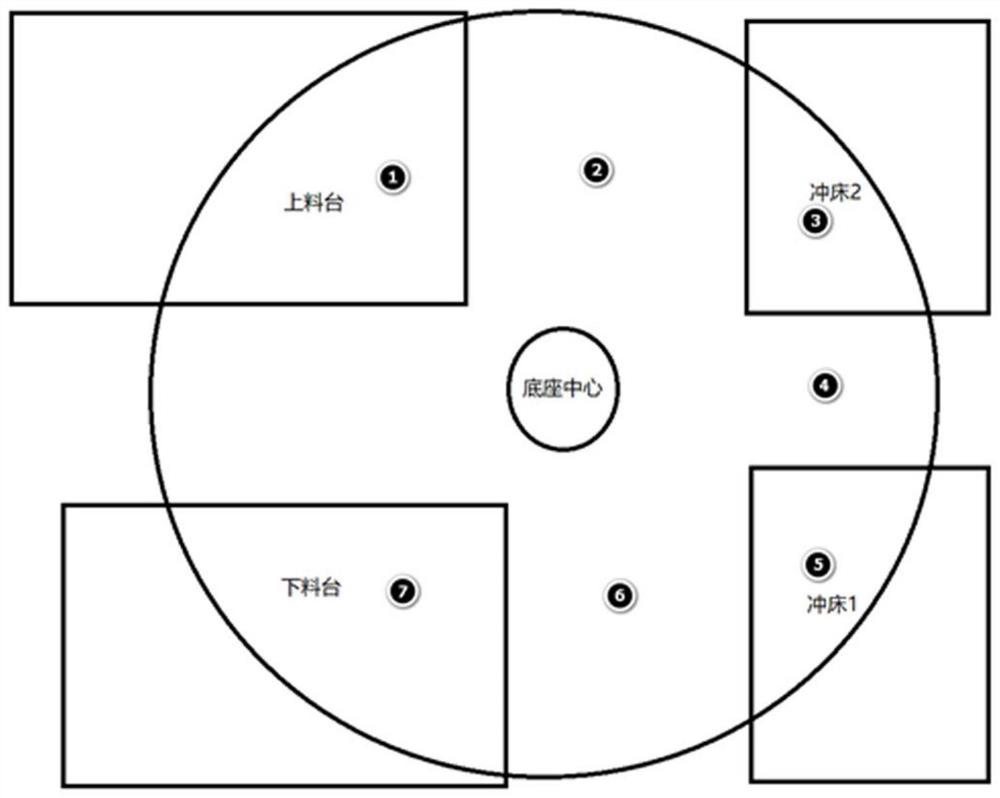

[0032] 1) Equipment running path, as attached Figure 4 , according to the reverse order of the path, formulate the path for the device to return to the initial position;

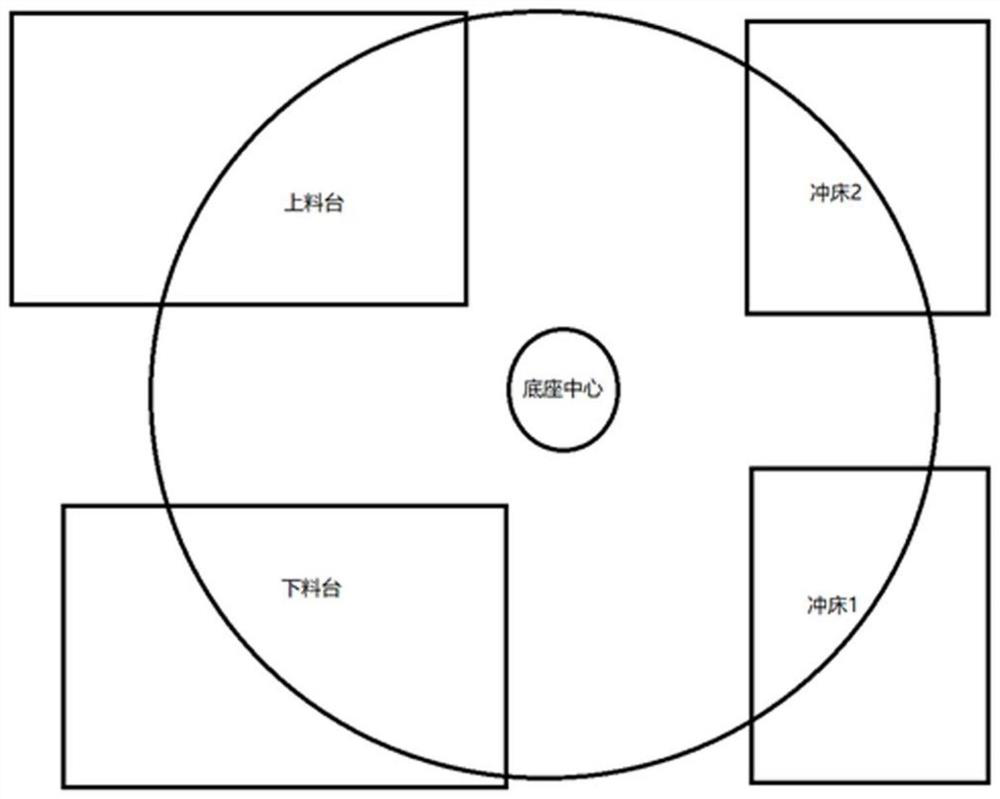

[0033] 2) Analyze the layout of peripheral equipment and list the existence of all equipment, as attached figure 1 ;

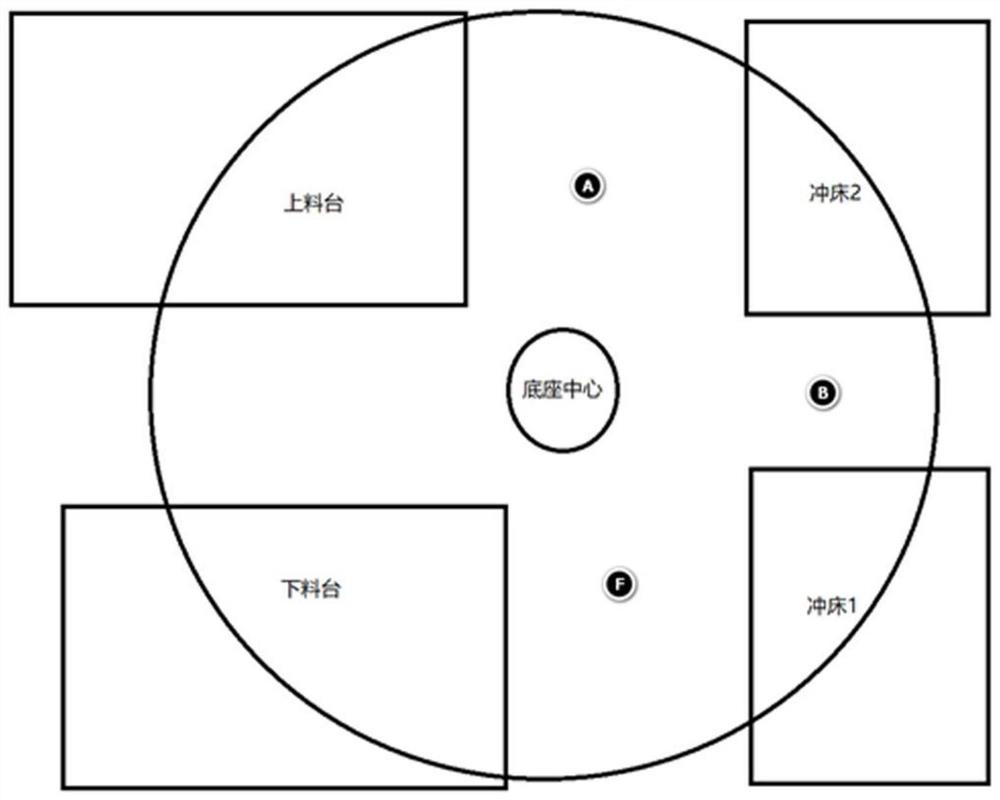

[0034] 3) According to the interference of peripheral equipment, set a first-level key point in the nearest non-interference area close to each equipment, as shown in the attached figure 2 , and make the path of returning to the initial position of the equipment formulated according to the reverse order of the operating path of the equipment in 1) coincide with the first-level key point, forming a safe return to the initial position path passing through the first-level key point;

[0035] 4) Take the first-level key point as the center, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com