Anti-dandruff shampoo and preparation system and processing method thereof

A preparation system, shampoo technology, applied in the direction of manufacturing tools, pharmaceutical formula, hair care, etc., can solve the problems of not being able to beat the raw materials to produce juice, extract the original solution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

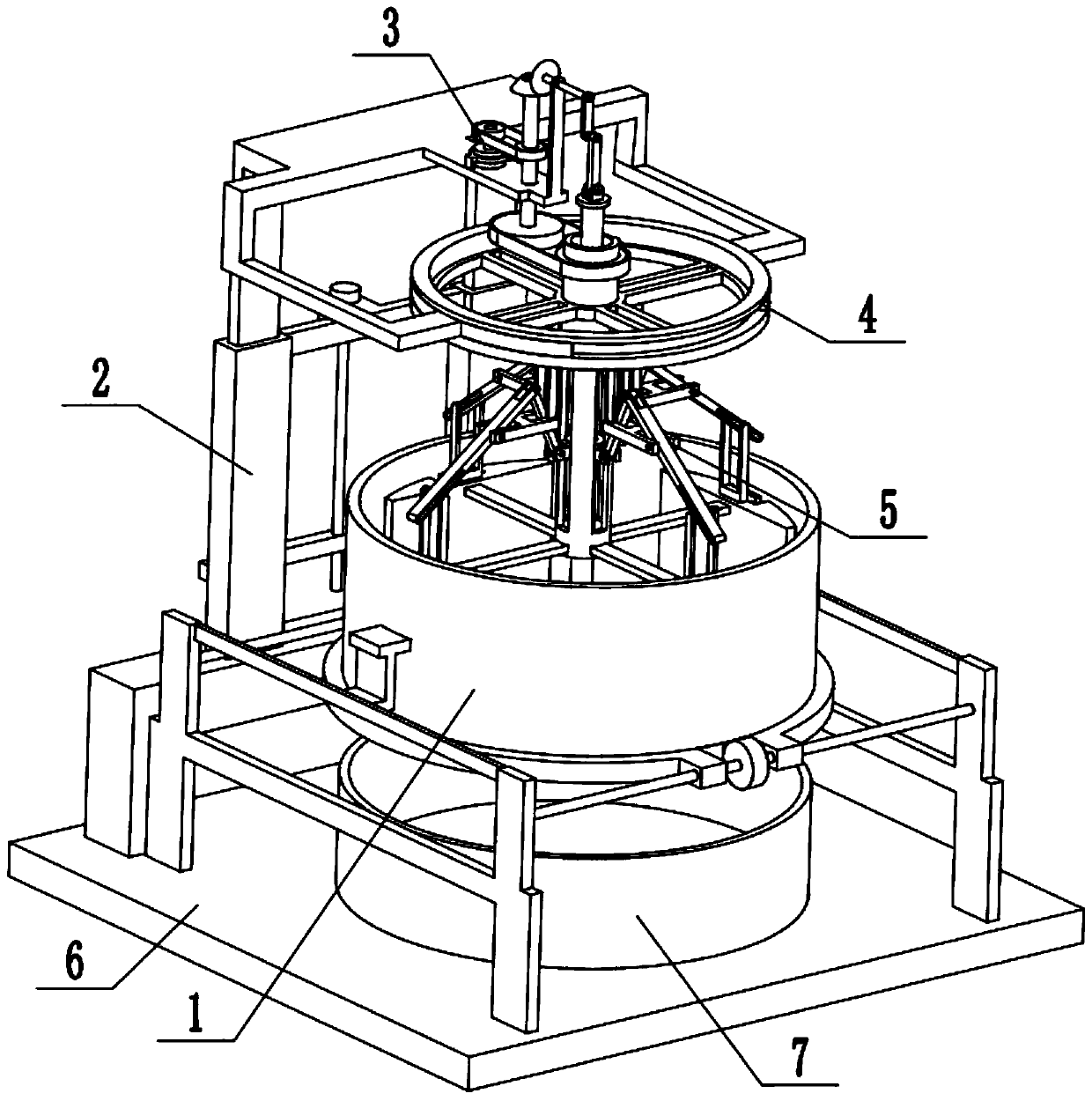

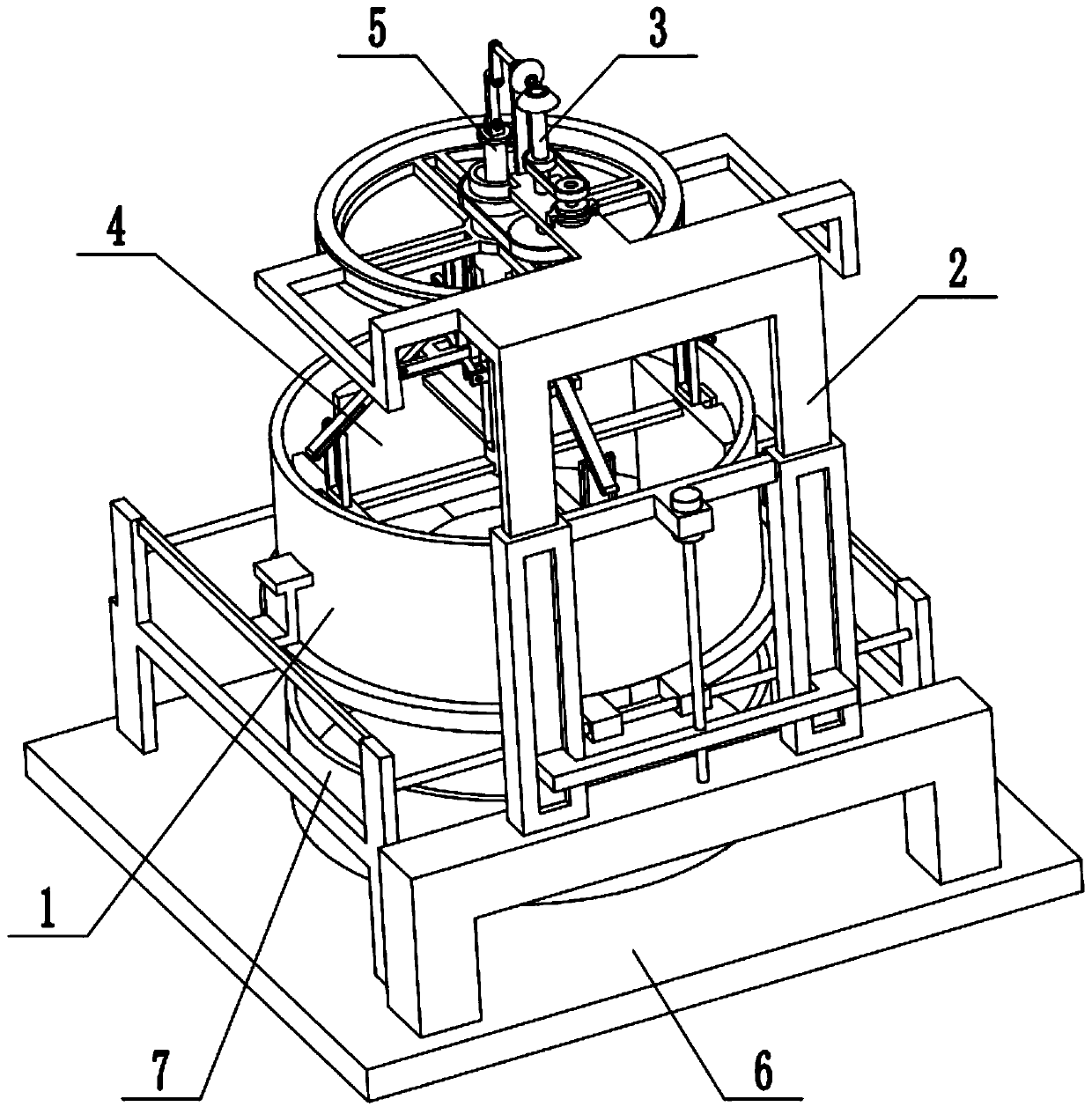

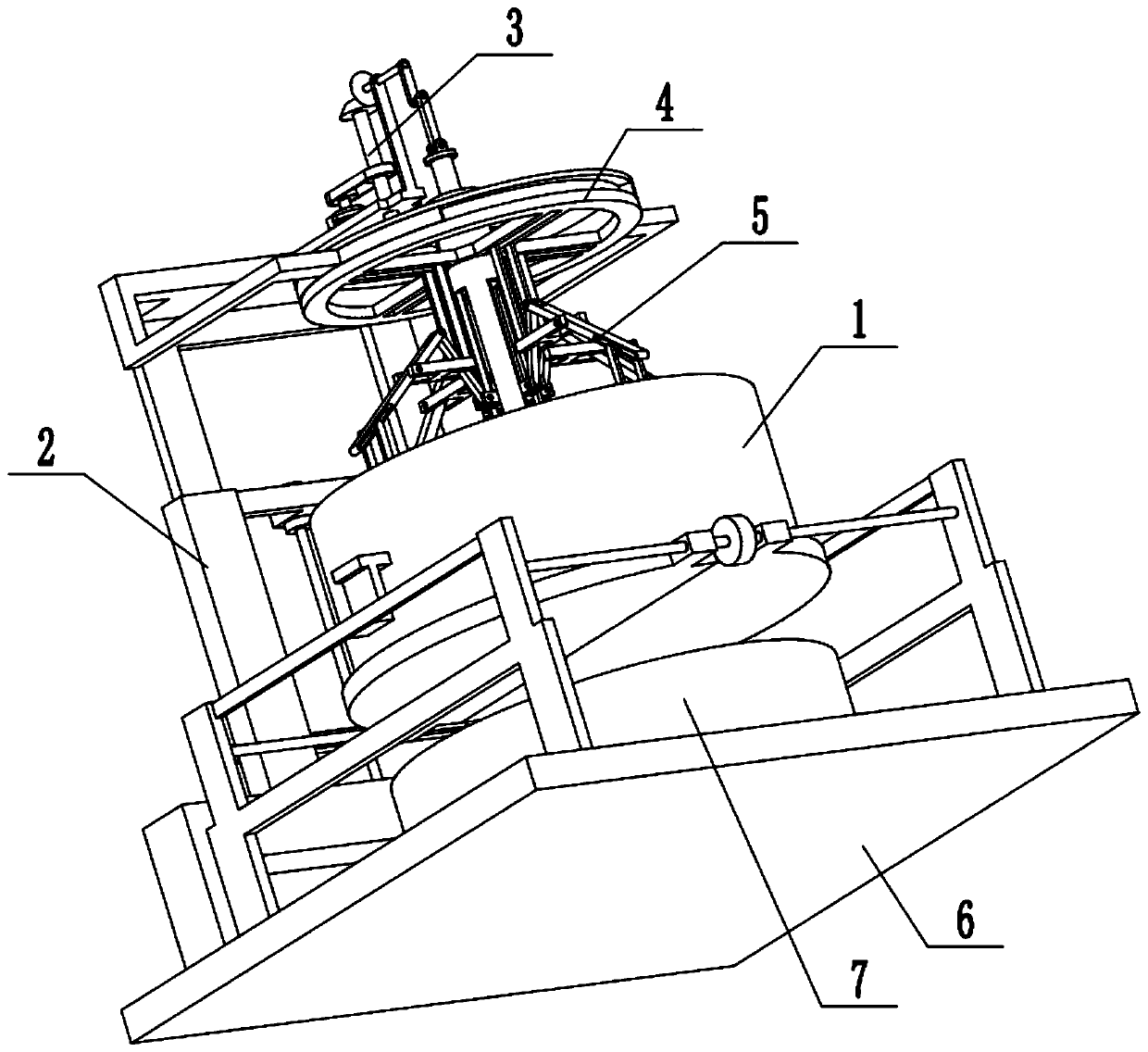

[0033] Combine below Figure 1-10 Describe this embodiment, a preparation system for anti-dandruff shampoo, including a material extrusion cylinder assembly 1, a lifting adjustment mechanism 2, a material rotating extrusion mechanism 3, a power output mechanism 4, an extrusion driving mechanism 5, a base 6 and a material A collection box 7, the material extrusion cylinder assembly 1 is fixedly connected to the base 6, the material collection box 7 is placed on the base 6, the material collection box 7 is located below the material extrusion cylinder assembly 1, and the lifting adjustment mechanism 2 is fixedly connected to Behind the material extrusion cylinder assembly 1, the material rotary extrusion mechanism 3 is arranged on the upper end of the lifting adjustment mechanism 2, the upper end of the power output mechanism 4 is arranged on the lifting adjustment mechanism 2, and the lower end of the power output mechanism 4 is located on the material extrusion cylinder assembl...

specific Embodiment approach 2

[0035] Combine below Figure 1-10 To illustrate this embodiment, the material extrusion cylinder assembly 1 includes a side frame 1-1, a guide rod 1-2, a bidirectional screw 1-3, a bottom plate 1-4, a screw ring 1-5, and a circular cylinder 1 -6 and the fixed frame 1-7; the guide rod 1-2 is fixedly connected to the rear end of the two side frames 1-1, and the two-way screw rod 1-3 is rotated and connected to the front ends of the two side frames 1-1. The rear ends of the two bottom plates 1-4 are symmetrically slidably connected to the guide rod 1-2, and the front ends of the two bottom plates 1-4 are connected to the two ends of the two-way screw rod 1-3 through thread fit, and the screw ring 1-5 is fixedly connected. In the middle of the two-way screw 1-3, the two ends of the circular tube 1-6 are respectively fixedly connected to a fixed frame 1-7, and the two fixed frames 1-7 are respectively fixedly connected to the two side frames 1-1, and the circular The bottom surfac...

specific Embodiment approach 3

[0037] Combine below Figure 1-10 To illustrate this embodiment, the lift adjustment mechanism 2 includes a portal frame 2-1, a rectangular hollow column 2-2, a rectangular through slot 2-3, a slide bar 2-4, a U-shaped plate 2-5, and a drive motor I2 -6, lead screw 2-7, top frame plate 2-8, shift fork 2-9, horizontal shaft frame plate 2-10 and vertical shaft frame plate 2-11; portal frame 2-1 is fixedly connected to base 6 On the top, two rectangular hollow columns 2-2 are fixedly connected to the portal frame 2-1, and the rear ends of the two rectangular hollow columns 2-2 are respectively provided with a rectangular through groove 2-3, and the two ends of the U-shaped plate 2-5 The two ends of the U-shaped plate 2-5 are respectively fixedly connected to a sliding rod 2-4, and the two sliding rods 2-4 are respectively slidingly fitted and connected to the two rectangular hollow slots. In the column 2-2, the driving motor I2-6 is fixedly connected between two rectangular holl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com