Marine mute door structure

A quiet, marine technology, applied in ship lock devices, ship construction, building construction, etc., can solve problems such as metal deformation, affecting user experience, harshness, etc., and achieve the effects of reducing noise, facilitating promotion and use, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

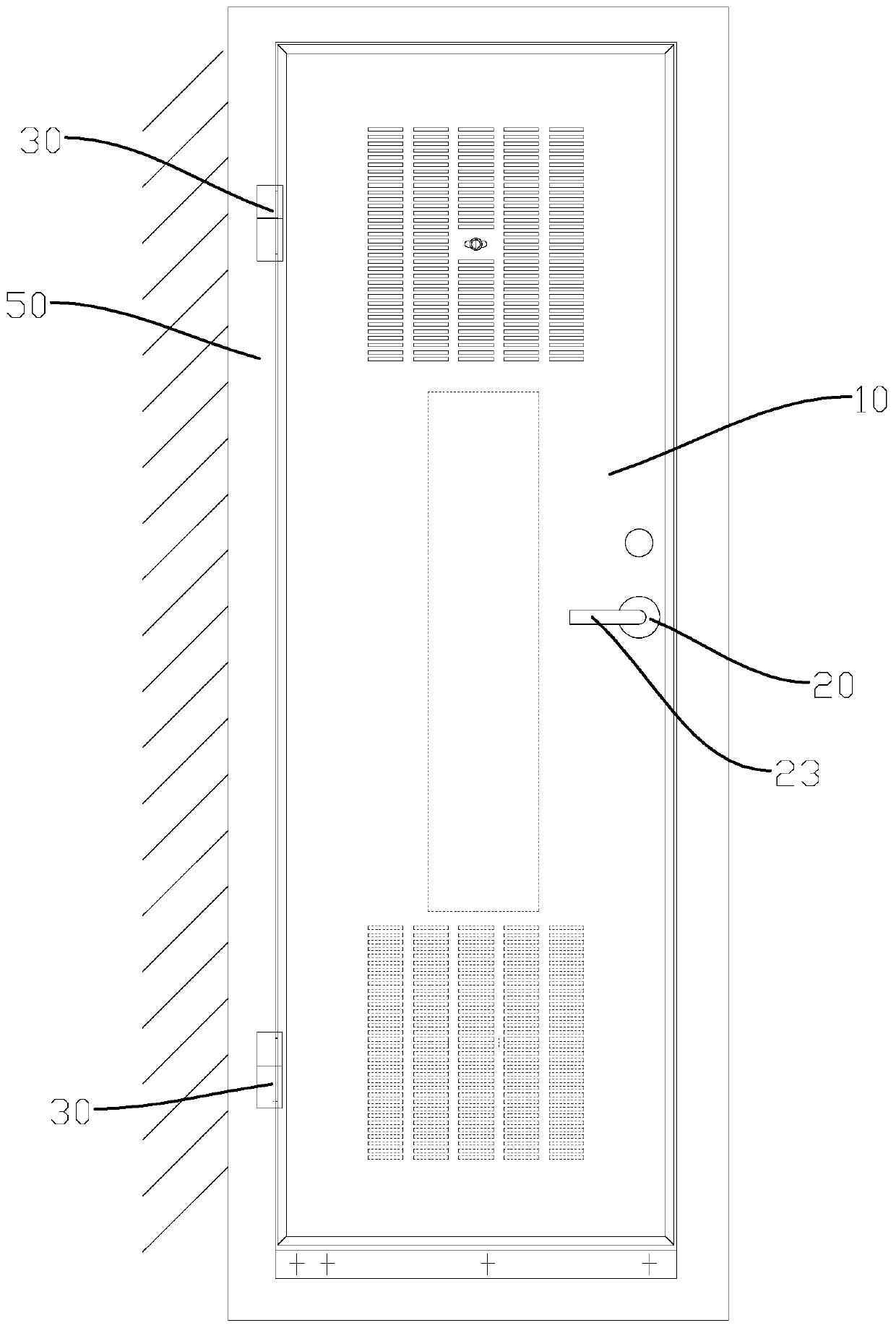

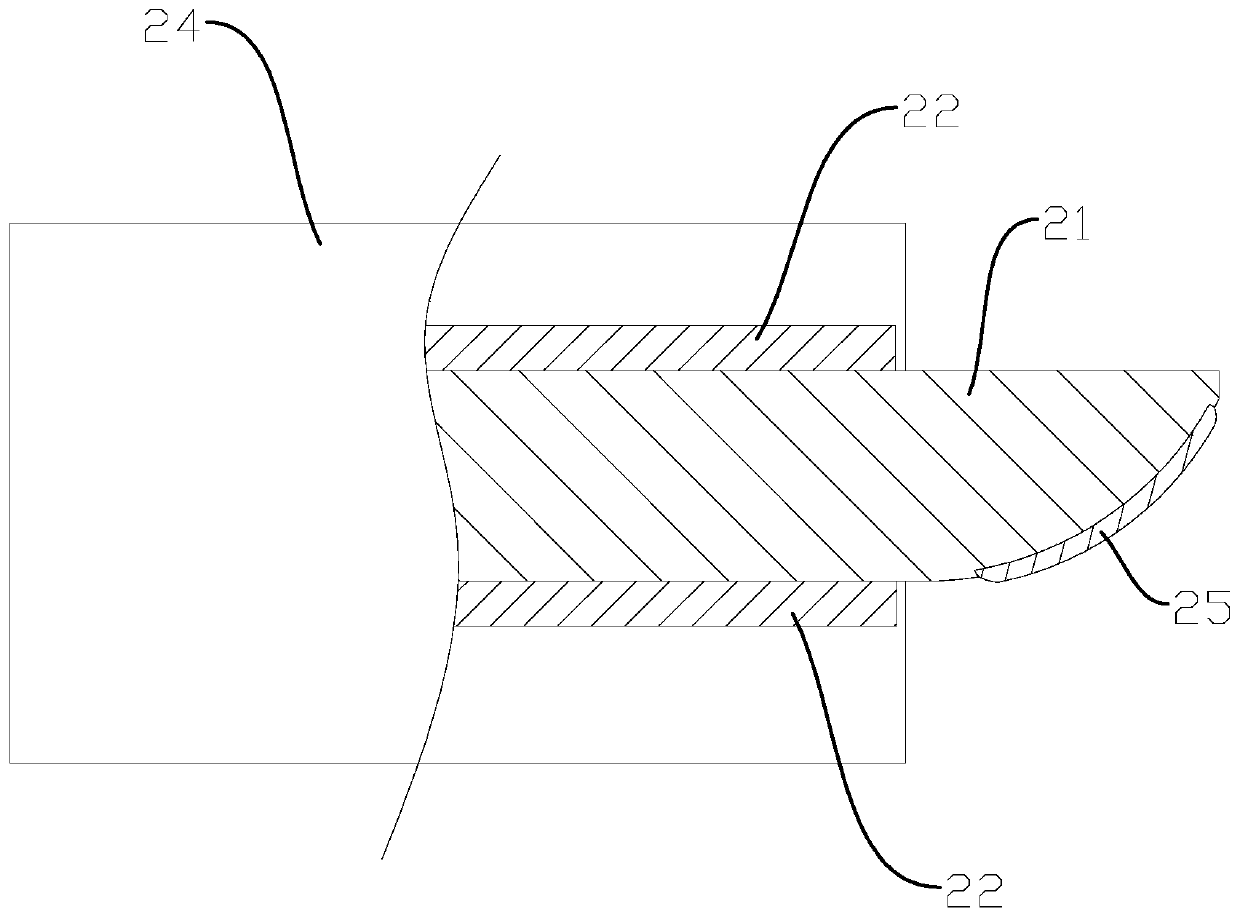

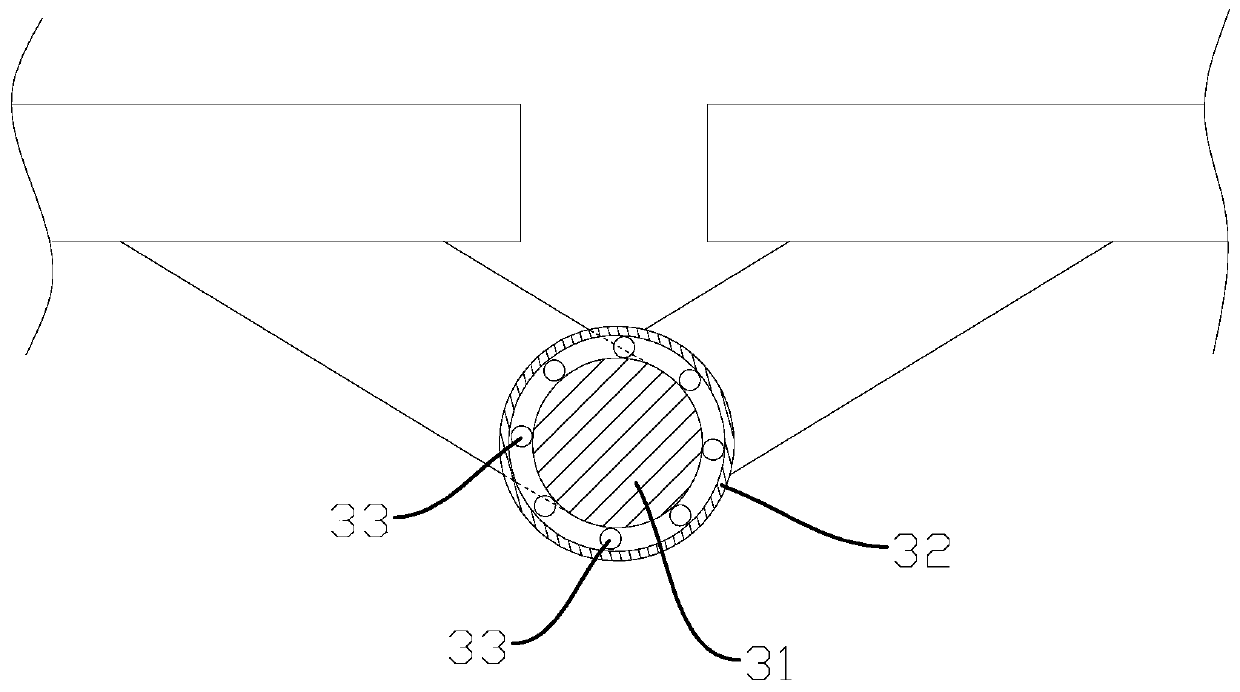

[0021] refer to Figure 1 to Figure 3 , the first embodiment of the present invention, a marine silent door structure, including a door body 10, the door body 10 is provided with a door lock 20, the door lock 20 includes a guide sleeve 22 and a lock slidingly arranged in the guide sleeve 22 The tongue 21, the guide sleeve 22 and / or the lock tongue 21 are provided with a first sound-absorbing portion located on the contact surface between the guide sleeve 22 and the lock tongue 21 or between the guide sleeve 22 and the lock tongue 21, the first sound-absorbing portion For non-metallic material. In the present invention, since the first noise-absorbing part of non-metallic material is set on the contact surface between the lock tongue 21 and the guide sleeve 22 or between the guide sleeve 22 and the lock tongue 21, during the expansion and contraction of the lock tongue 21, it can effectively It avoids harsh noise caused by metal friction, and even in the case of insufficient l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com