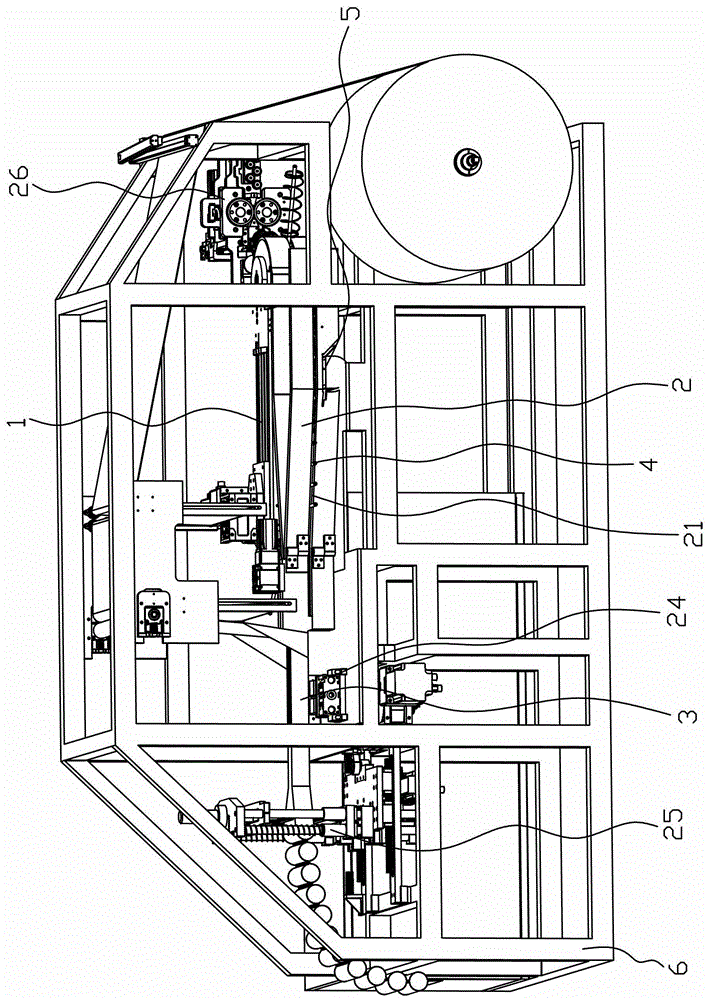

Liquid-cooled mattress spring processing plant with new conveyor system

A liquid cooling and conveying system technology, applied in conveyors, conveyor objects, household appliances, etc., can solve the problems of slow spring cooling, large spring wear, long time consumption, etc., to improve work efficiency, protect operators, avoid The effect of harsh noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

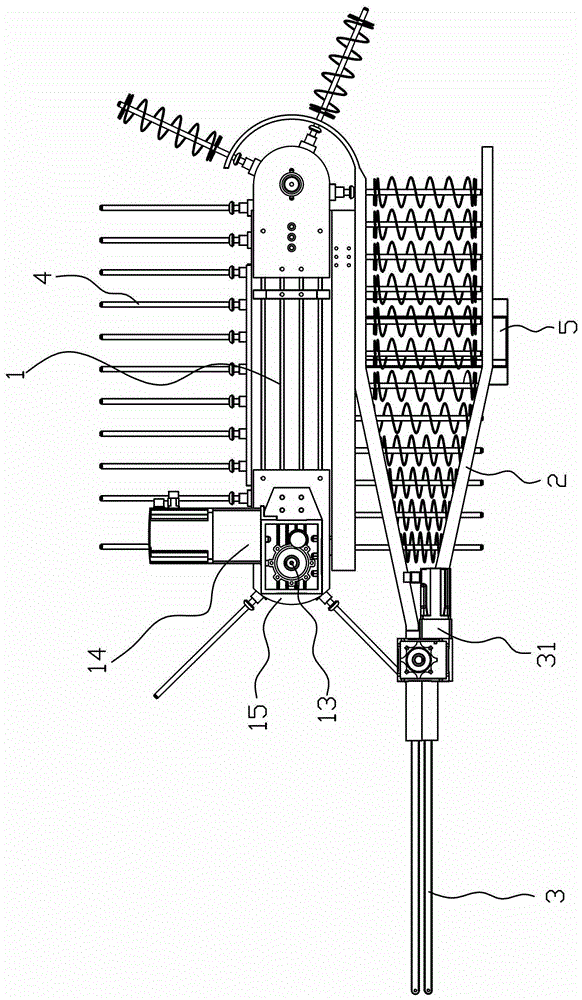

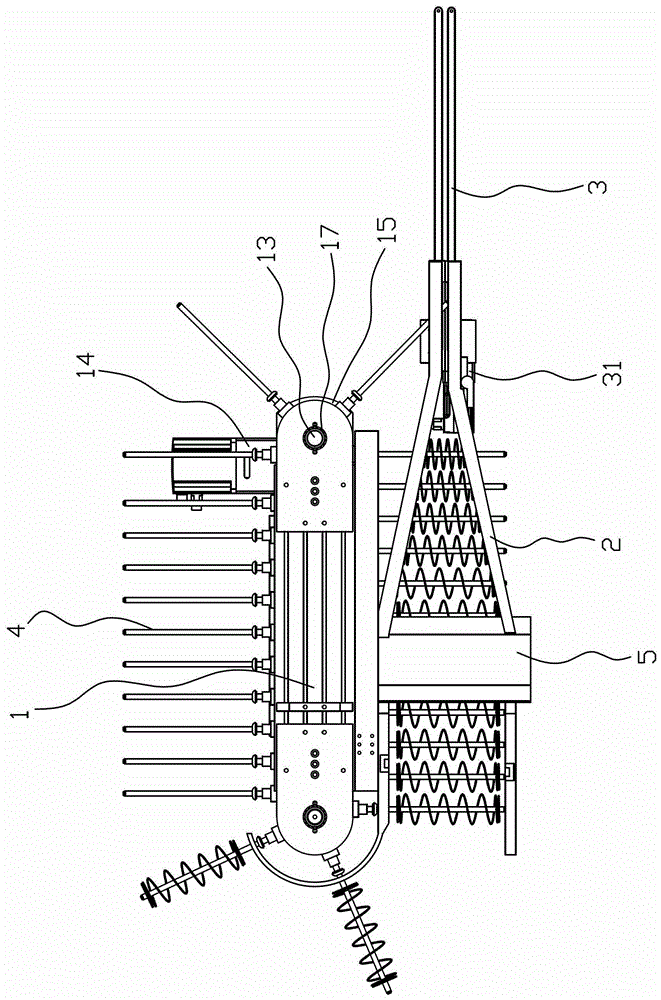

[0020] refer to Figure 1-6 , a mattress spring processing equipment with a new type of conveying system and capable of liquid cooling, including a frame 6, which is a frame-type frame body, and a spring winding machine 26 and a crawler belt conveyor are installed on the frame 6 1. The crawler belt conveying device 1 is provided with an endless crawler belt 11, and the spring conveying rod 4 extending outward is arranged on the circumferential direction of the circular crawler belt 11. The crawler belt conveying device 1 includes a crawler belt guide rail 12, and the Crawler belt shafts 13 are installed at both ends of the track guide rail 12, and the annular crawler belt 11 is paved in the track of the above-mentioned crawler track guide rail 12 after bypassing the two crawler belt rotation shafts 13. The crawler belt rotation shaft 13 is connected with an annular crawler belt drive motor 14, The endless track driving motor 14 drives the track rotating shaft 13 to rotate and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com