Non-woven fabric PE hand bag and manufacturing method thereof

A technology of non-woven fabrics and handbags, applied in textile/flexible product manufacturing, bags, sacks, etc., can solve the problems of resource waste, unsightly, thin materials, etc., and achieve waterproof and firm, wide application range, and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

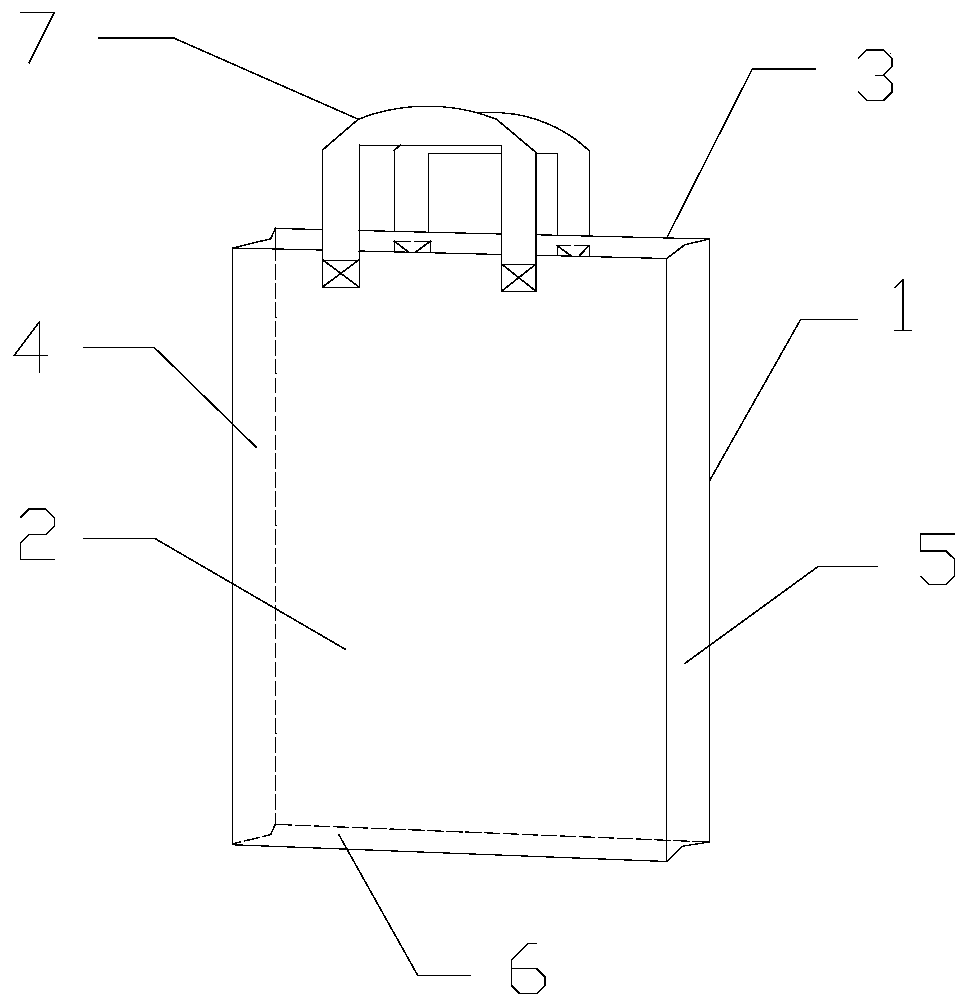

[0023] A non-woven fabric coated handbag, comprising a rectangular bag body, the rectangular bag body is provided with folding indentations, the rectangular bag body is stretched along the folding indentations to form front and rear side walls, left and right side walls and bottom side walls, the rectangular bag body The two corners of the lower end of the bag are turned inward and connected to the inside of the left and right side walls by hot pressing, and a handle is provided at the opening of the rectangular bag body, and the handle is fixedly connected to the rectangular bag body by hot pressing or sewing; Both the rectangular bag body and the handle are made of a composite film, and the composite film includes a non-woven fabric layer, a PP coating layer and a BOPP film layer arranged in sequence.

[0024] Its preparation method comprises the following steps:

[0025] 1) Using PP as the raw material, the film is coated on the surface of the non-woven fabric through the l...

Embodiment 2

[0031] A non-woven fabric coated handbag, comprising a rectangular bag body, the rectangular bag body is provided with folding indentations, the rectangular bag body is stretched along the folding indentations to form front and rear side walls, left and right side walls and bottom side walls, the rectangular bag body The two corners of the lower end of the bag are turned inward and connected to the inside of the left and right side walls by hot pressing, and a handle is provided at the opening of the rectangular bag body, and the handle is fixedly connected to the rectangular bag body by hot pressing or sewing; Both the rectangular bag body and the handle are made of a composite film, and the composite film includes a PP non-woven fabric layer, a PE material coating layer and a BOPP film layer arranged in sequence.

[0032] Its preparation method comprises the following steps:

[0033] 1) Using PE as the raw material, the surface of the PP non-woven fabric is coated by a lamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com