Elavator main rope replacement device and method

A main rope and rope technology is applied in the field of main rope replacement devices to achieve the effect of easy replacement operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

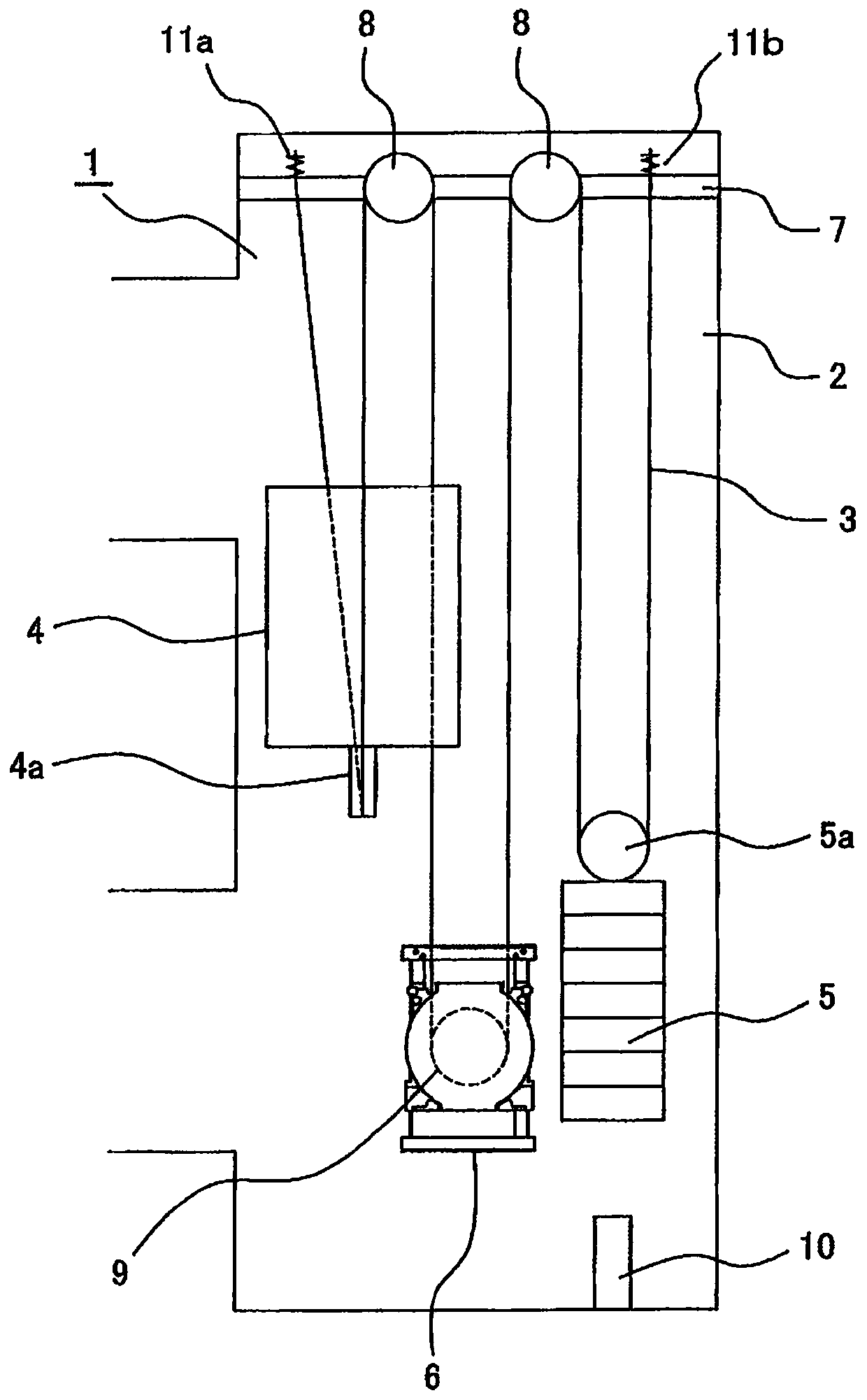

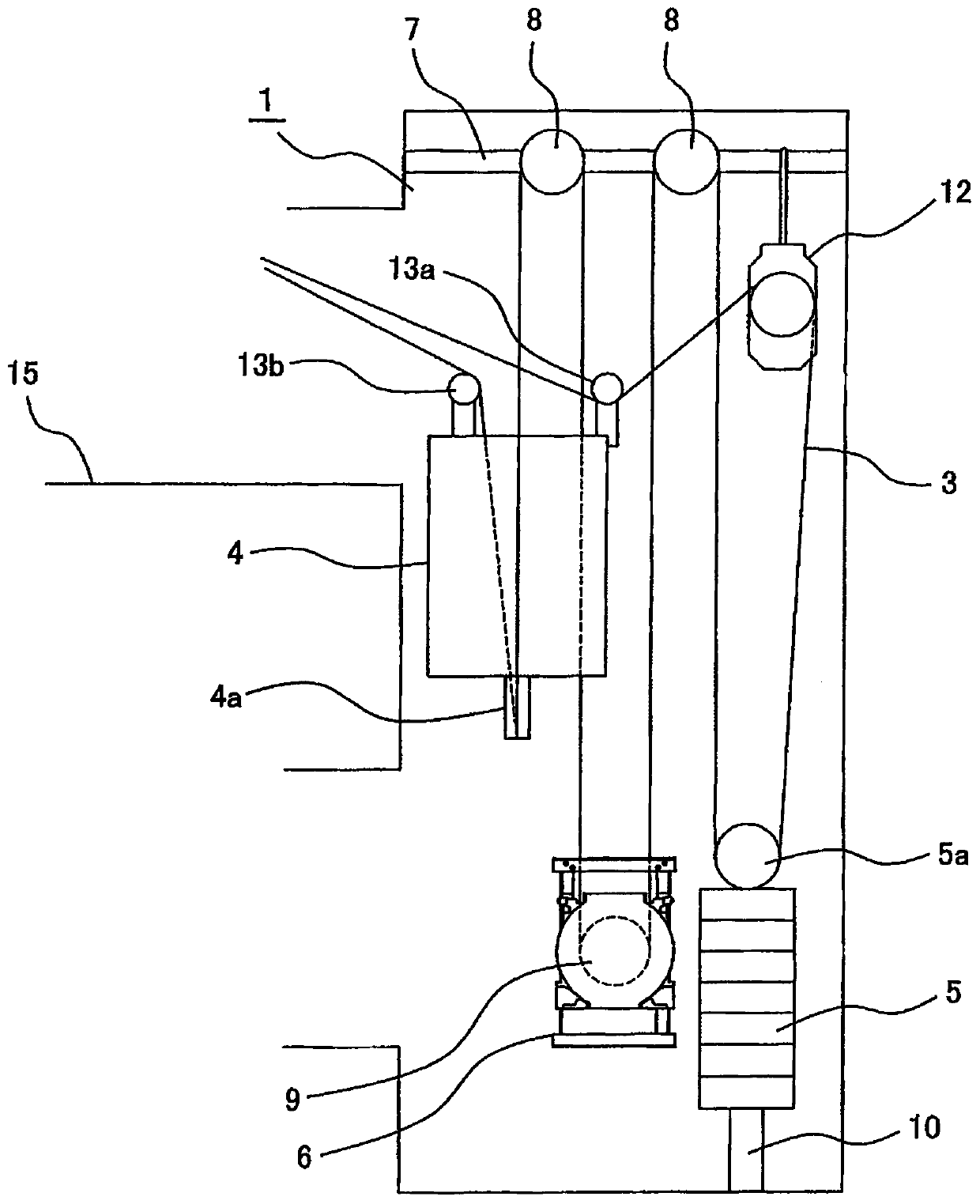

[0027] Embodiments of the present invention will be described with reference to the drawings. figure 1 It is a schematic configuration diagram showing main parts of an elevator to which the main rope replacement device according to the embodiment of the present invention is applied.

[0028] figure 1 The illustrated machine-room-less elevator 1 is an elevator in which a car 4 and a counterweight 5 connected via main ropes 3 are moved up and down by the driving force of a hoist 6 in a hoistway 2 installed in a building. A top beam 7 is arranged on the top in the hoistway 2, and two top pulleys 8 are installed on the top beam 7. The hoist 6 is provided at a lower position in the hoistway 2, and has a hoist sheave 9 that rotates with a motor (not shown) as a drive source. The balance weight 5 is vertically guided along two guide rails (not shown), and a buffer 10 is provided at the inner bottom of the hoistway 2 to face the lower surface of the balance weight 5 .

[0029] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com