Wall-mounted clothes treatment appliance

A kind of clothes processing equipment and wall-mounted technology, which is applied in other washing machines, textiles and papermaking, household appliances, etc., can solve the problems of bruising users, loss of widening function outside the equipment, and difficulty in removing and cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

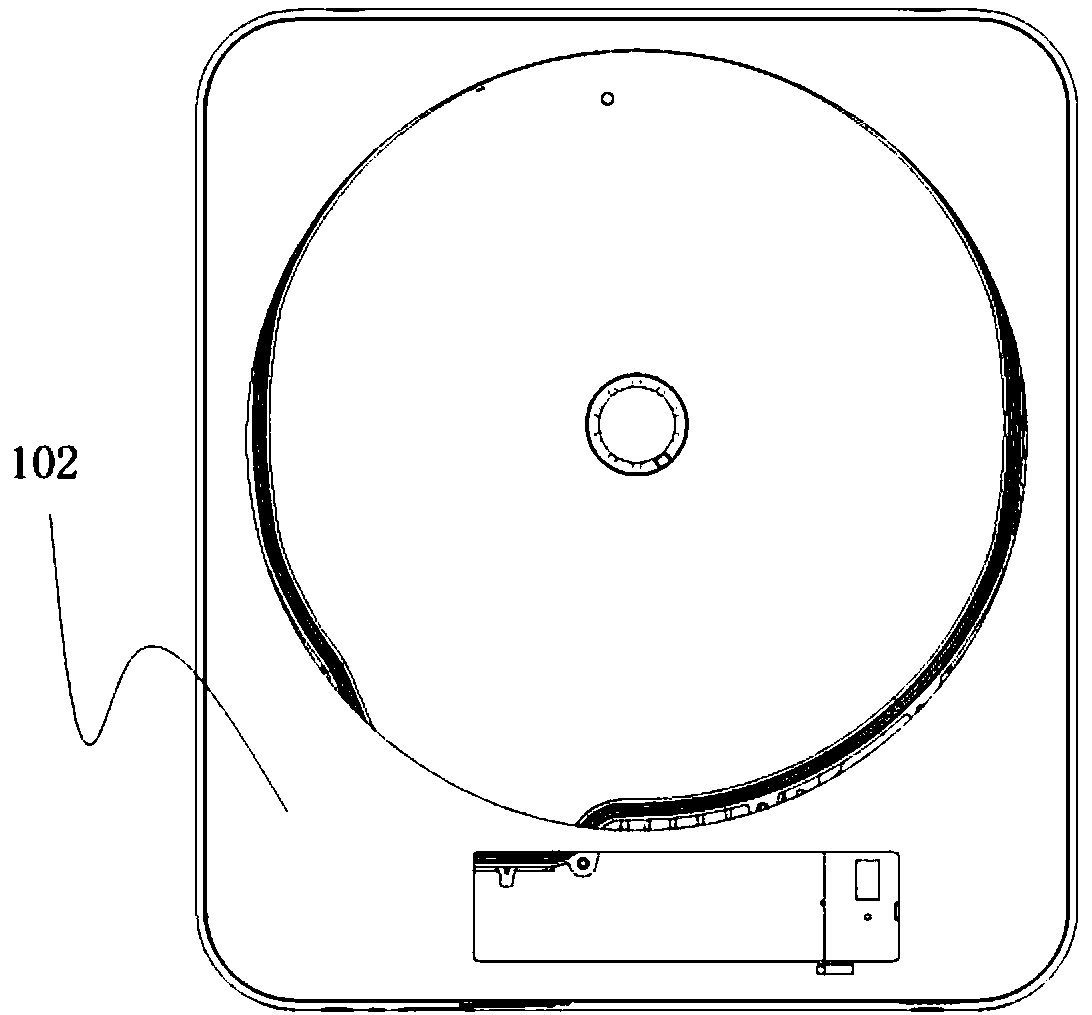

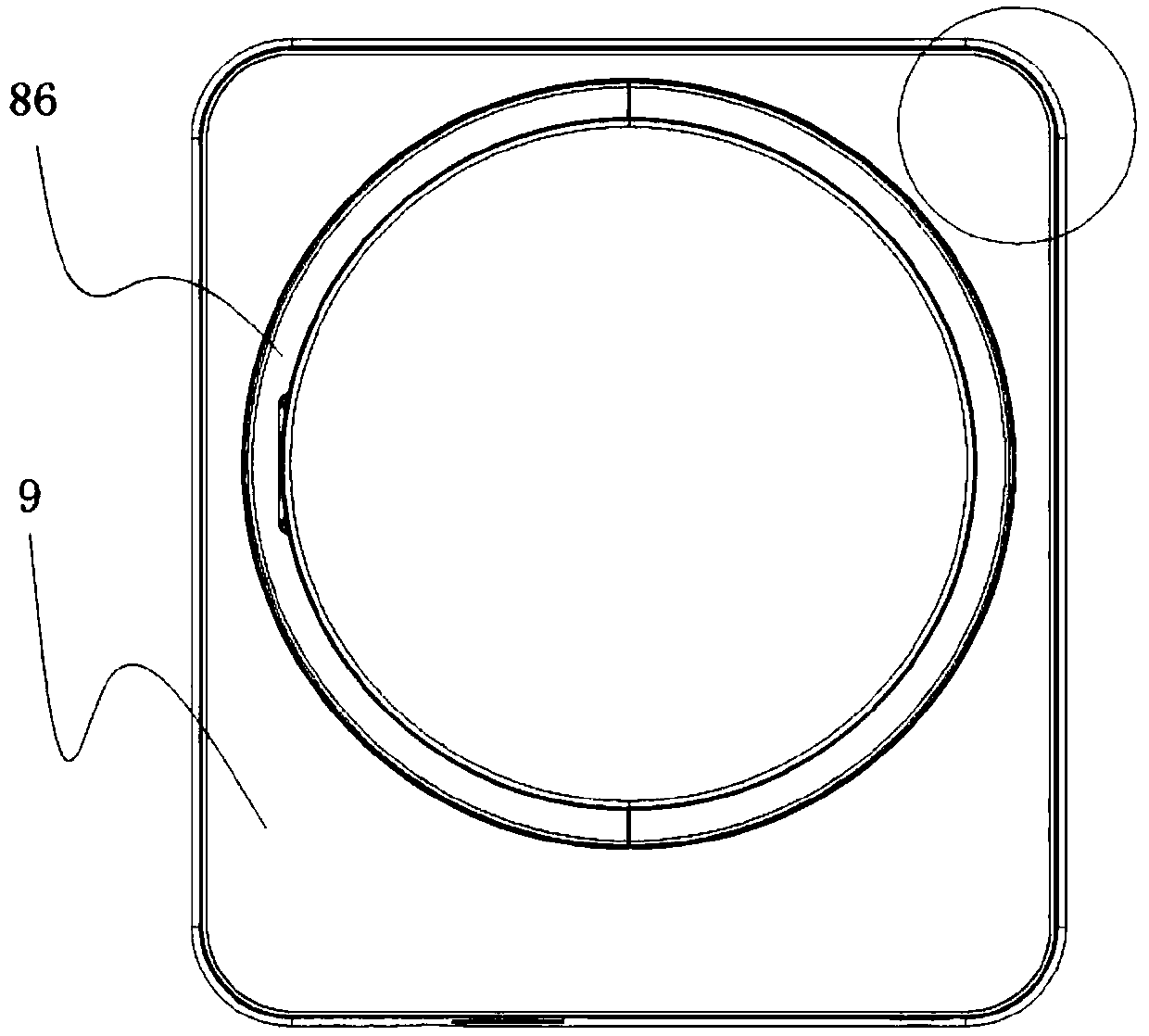

[0132] Such as Figure 1 to Figure 6 As shown, in the wall-mounted laundry processing device described in this embodiment, the front trim panel 9 is a straight flat plate structure, which completely covers the side of the housing 10 corresponding to the laundry inlet. The flat plate-shaped structure can achieve a greater degree of shaping and shape retention on the front side of the wall-mounted laundry processing equipment, and reduce the space occupied by the equipment. The structure is also easy to process. Moreover, the flat plate structure is also easy to realize the user's personalized function expansion at this position. For example, set the front trim as a mirror structure, or set other easily removable structures on the front trim, such as hooks.

Embodiment 2

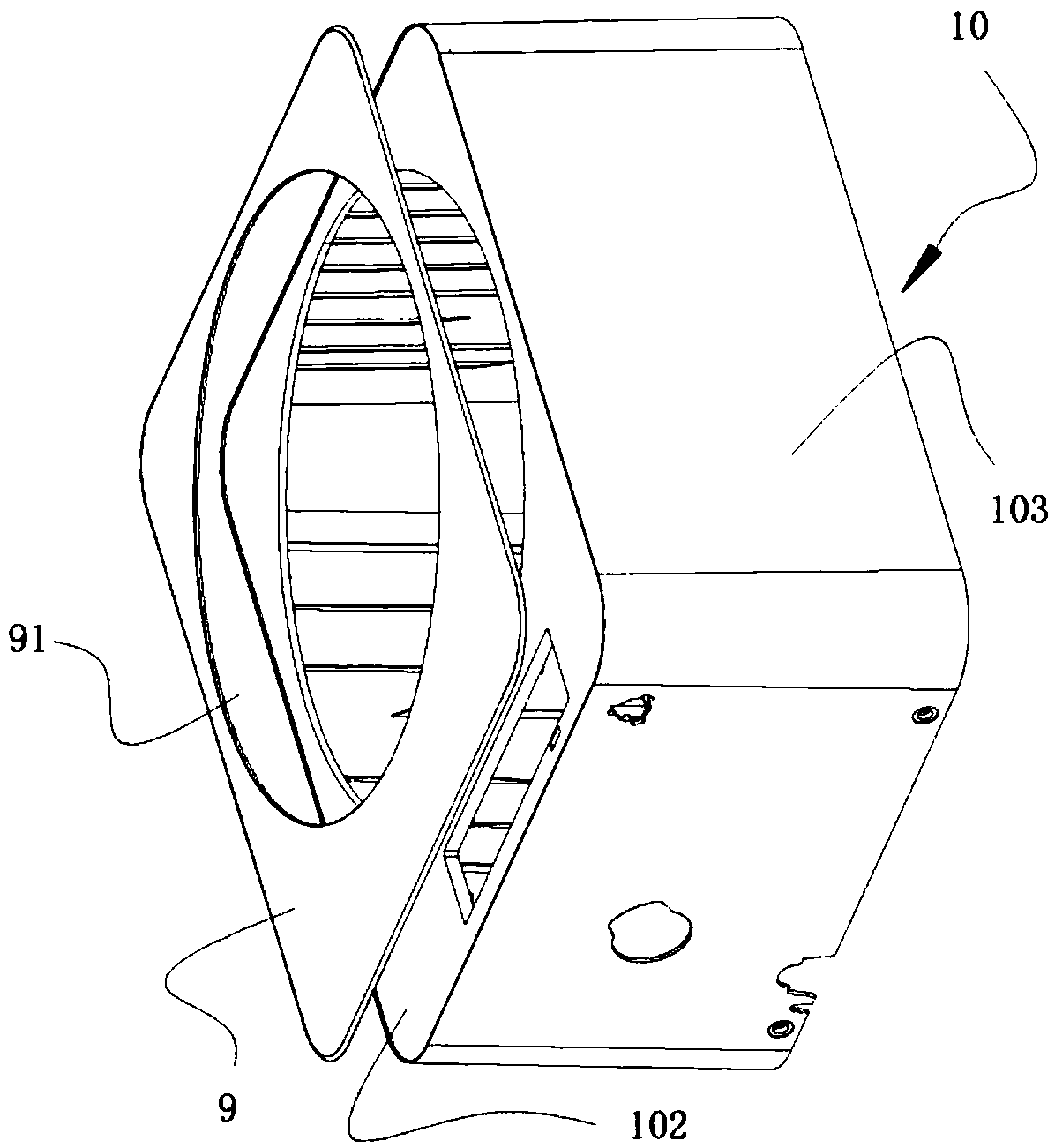

[0134] Such as Figure 1 to Figure 6 As shown, the difference between the wall-mounted laundry processing equipment in this embodiment and the above-mentioned embodiments is that: the housing 10 includes a front housing 102 on the side corresponding to the clothes insertion port, and the front housing 102 has a A side plate 103 constituting at least part of the profile of the device, the front housing 102 is connected with the side plate 103 to form a box-like structure. Preferably, the front housing 102 and the side panel 103 are integrally formed, and both are integrally formed. Further preferably, at least part of the side plate 103 is a barrel-shaped structure, forming a ring structure around the device when the device is in use. The front shell 102 constitutes at least part of the outline of the clothes inlet, and the front trim 9 completely covers the side of the front shell 102 facing the outside of the device. Since the front housing 102 will be provided with functio...

Embodiment 3

[0137] Such as Figure 1 to Figure 6 As shown, the difference between the wall-mounted laundry treatment equipment described in this embodiment and the above-mentioned embodiments is that: at least part of the front panel 9 is embedded in the housing 10, and the housing 10 wraps in at least two directions. At least part of the front trim 9 increases the connection performance between the front trim 9 and the casing 10, reduces the exposure of the front trim edge, and increases the integrity of the front trim and the casing, even if the front trim is subjected to external force The effect will not be separated or deformed.

[0138] Further, in this embodiment, the end of the side plate 103 adjacent to the clothes inlet protrudes from the front housing 102, and the side of the front housing 102 facing the outside of the device forms a groove shape with the side plate 103. structure. The groove-shaped structure is equivalent to the position of the clothes insertion port as a va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com