Coaming mounting structure and method for fabricated building

An installation structure and prefabricated technology, which is applied in the direction of building structure, construction, covering/lining, etc., can solve the problems of low installation efficiency and inconvenient operation, and achieve the effect of convenient operation and improved installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

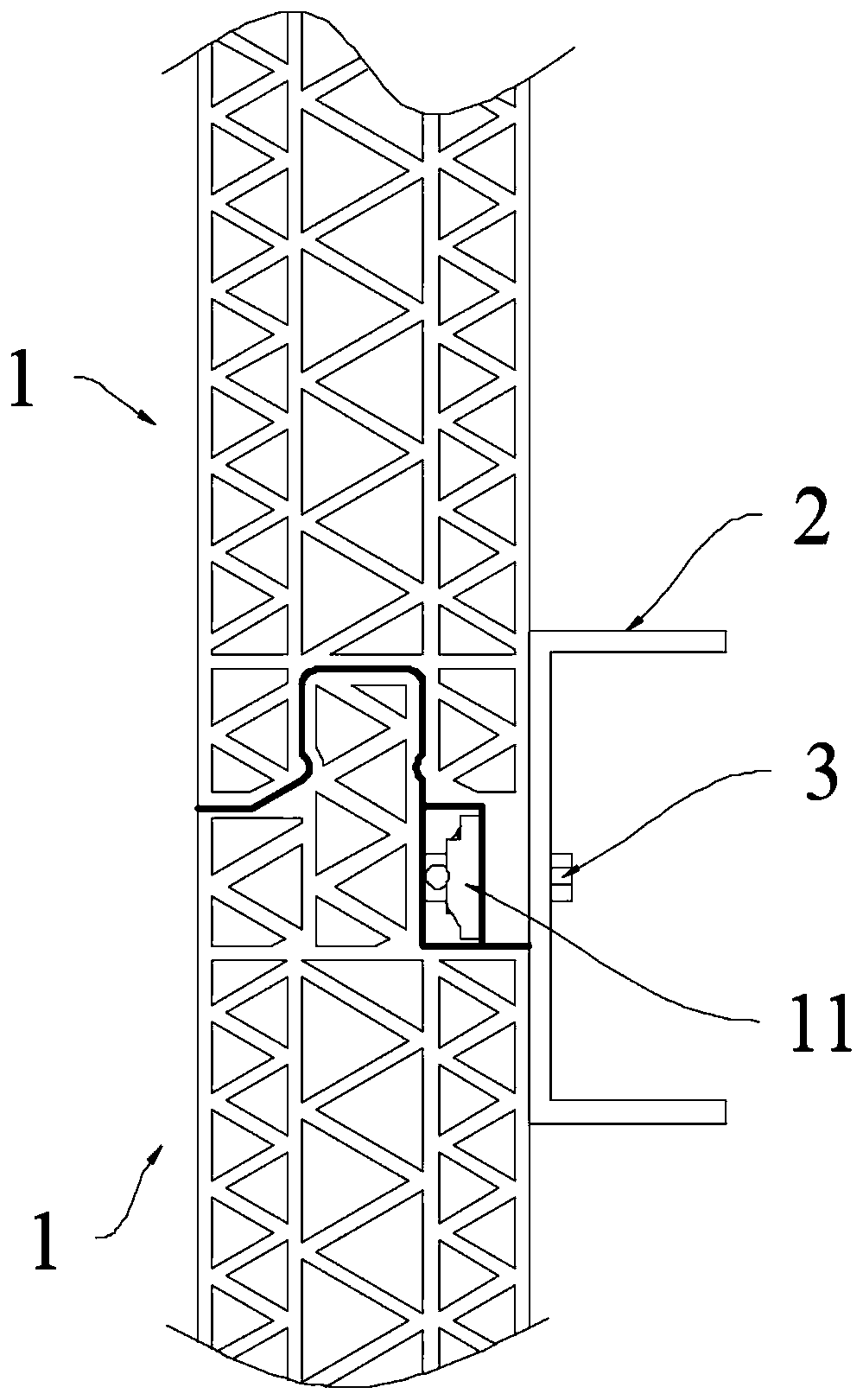

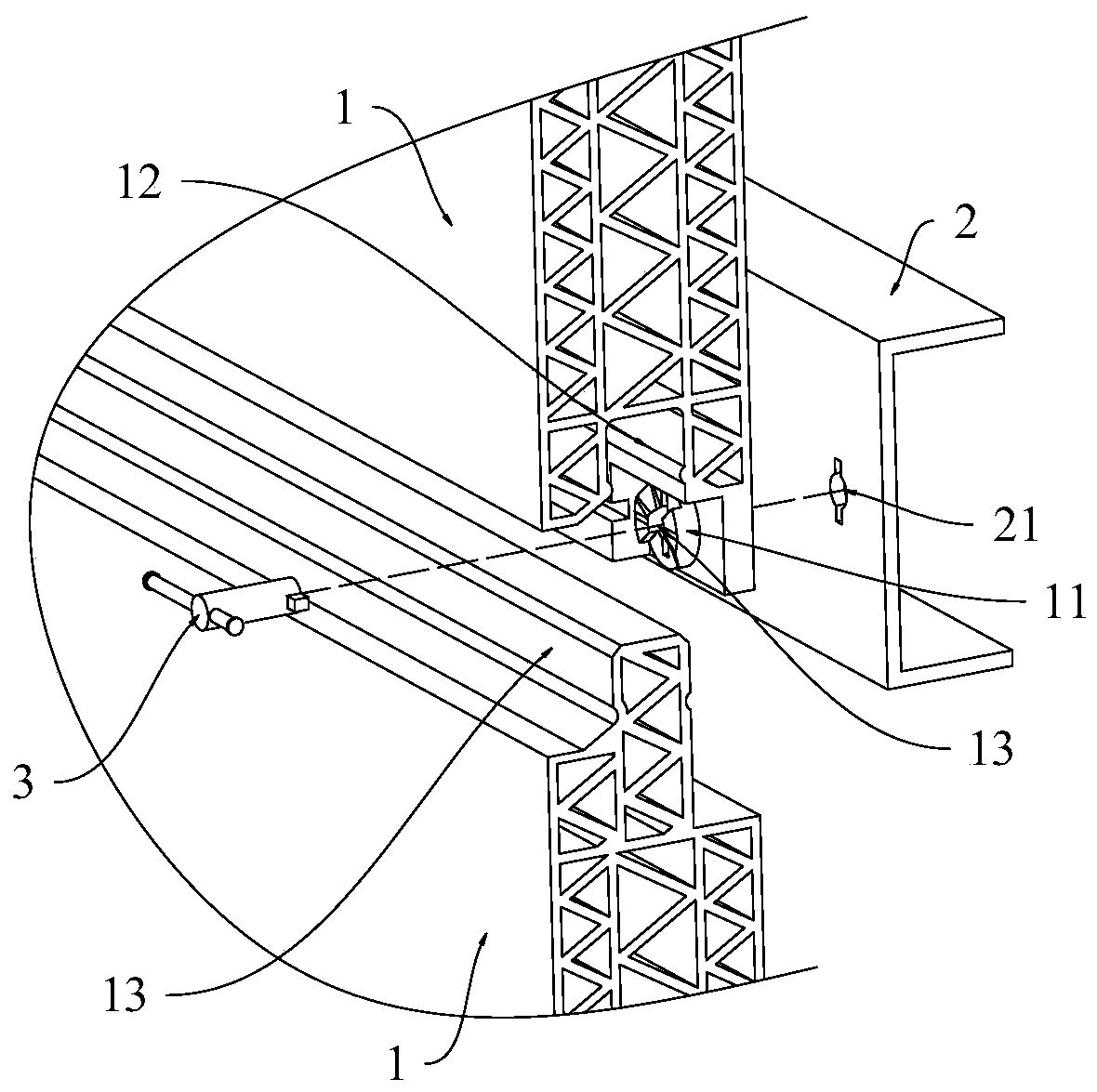

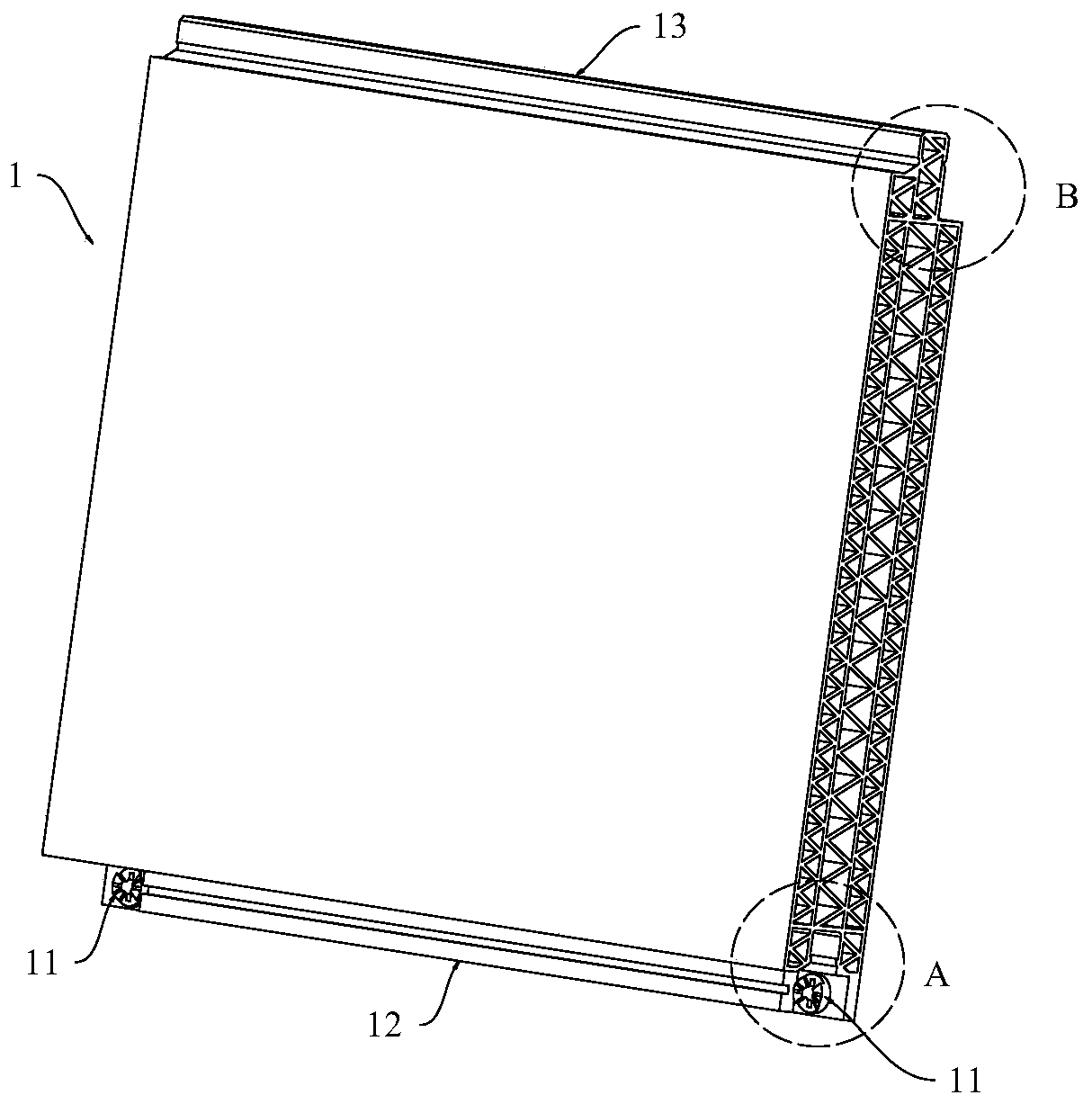

[0029] as attached Figure 1-2 The hoarding installation structure of the prefabricated building shown includes a hoarding 1 , a skeleton 2 and a fastener 3 ; the fastener 3 fixes the hoarding 1 to the skeleton 2 .

[0030] Specifically, as attached Figure 6 As shown, the fastener 3 includes a round bar portion 31; the tail end of the round bar portion 31 is fixedly provided with a locking portion 32, and when viewed from the axial direction of the round bar portion 31, the locking portion At least one side of 32 is exposed outside the round bar portion 31 (in this embodiment, both sides of the locking portion 32 are exposed outside the round bar portion 31), and the thickness of the locking portion 32 is smaller than the round bar portion 31. The diameter of the rod part 31; the head of the round rod part 31 is equipped with a rotating rod 33, and the rotating rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com