Anti-loosing screw rod

An anti-loosening and screw technology, applied in the direction of screws, nuts, bolts, etc., can solve the problems of screw and nut falling off, loosening of fixing parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

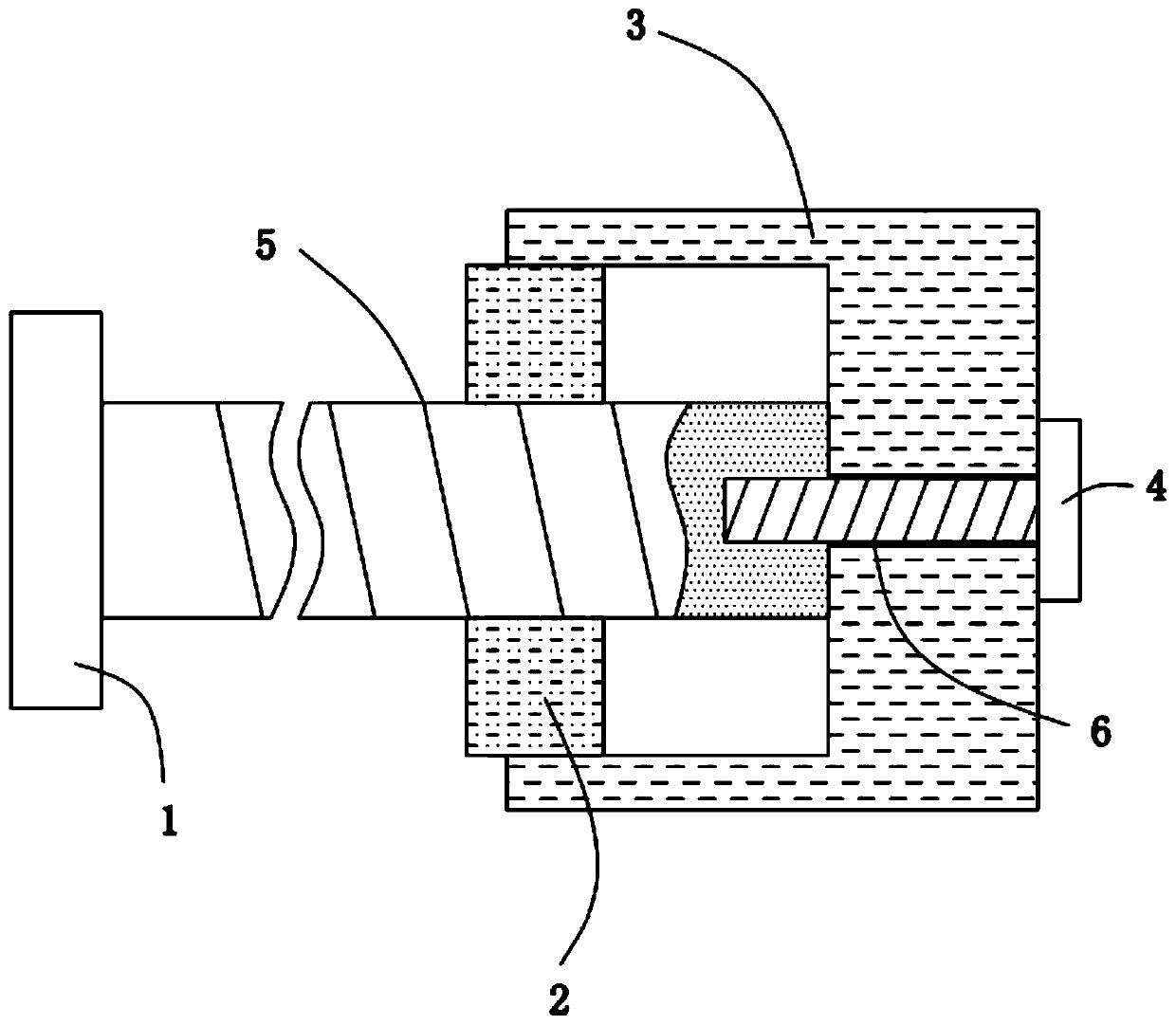

[0021] Please refer to figure 1 , in the first embodiment of the present invention, the anti-loosening screw includes: a hexagonal screw 1; a hexagonal nut 2, the hexagonal nut 2 is threaded on the outside of the hexagonal screw 1, and the hexagonal screw 1 runs through The hexagonal nut 2; the hexagonal nut cover 3, the hexagonal nut cover 3 is set on the outside of the hexagonal nut 2; a plurality of fixed screws 4, a plurality of fixed screw rods 4 run through the hexagonal Nut cover 3, and fixing screw 4 is threadedly connected with described hexagonal screw 1; First thread 5, described first thread 5 is set on the outside of described hexagonal screw 1; A plurality of second threads 6, a plurality of described The second threads 6 are provided on the outer sides of the plurality of fixing screws 4 respectively.

[0022] The hexagonal nut 2 is arranged in a regular hexagonal shape, and one side of the hexagonal nut sleeve 3 is provided with a regular hexagonal groove, and...

no. 2 example

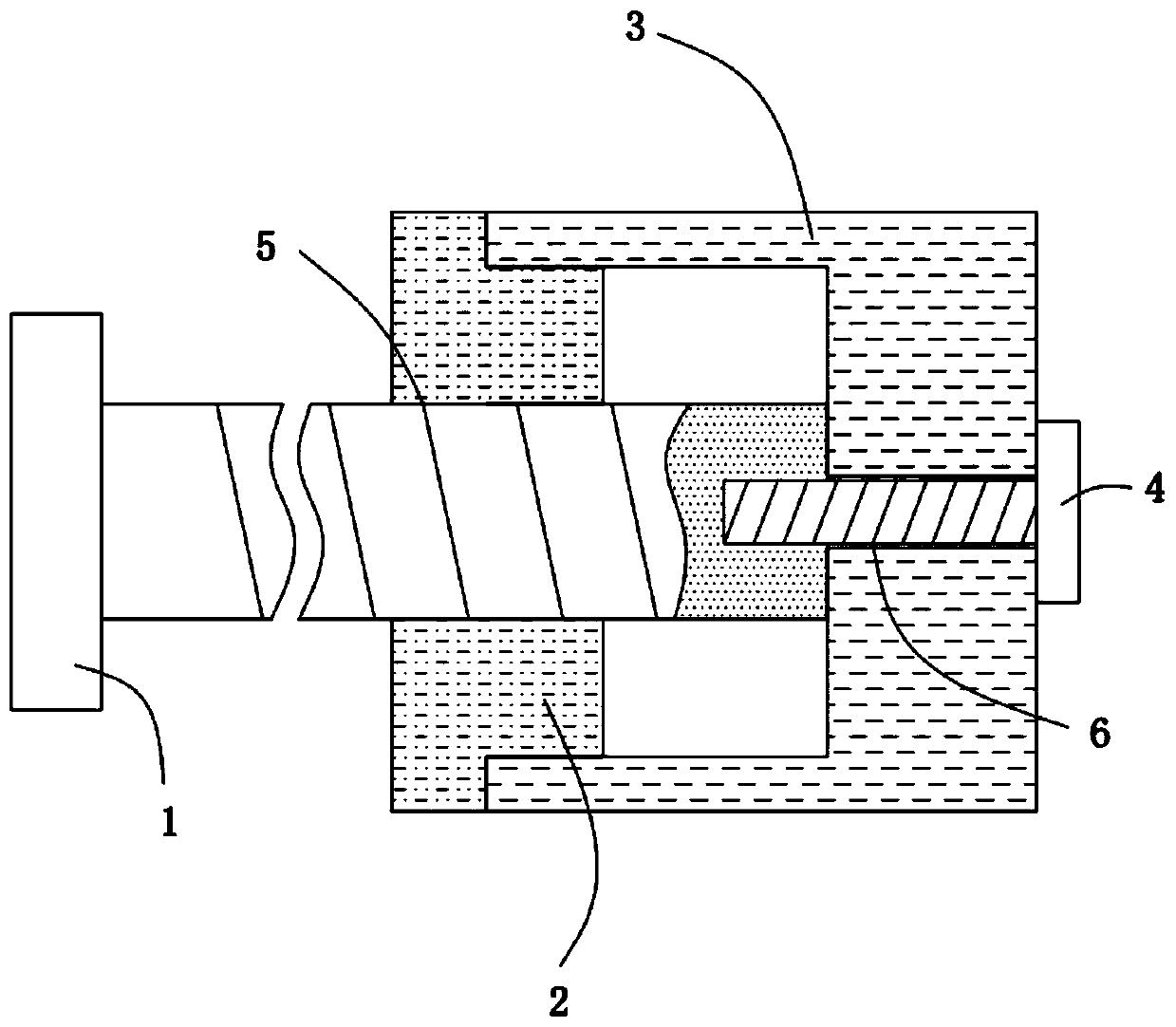

[0030] Based on the anti-loosening screw provided in the first embodiment of the present application, the second embodiment of the present application proposes another anti-loosening screw. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0031] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

[0032] Please refer to figure 2 The anti-loosening screw includes: a hexagonal screw 1; a hexagonal nut 2, the hexagonal nut 2 is threaded on the outside of the hexagonal screw 1, and the hexagonal screw 1 runs through the hexagonal nut 2; the hexagonal nut Cover 3, the hexagonal nut cover 3 is set on the outside of the hexagonal nut 2; a plurality of fixed screws 4, a plurality of fixed screw rods 4 run through the hexagonal nut cover 3, and the fixed...

no. 3 example

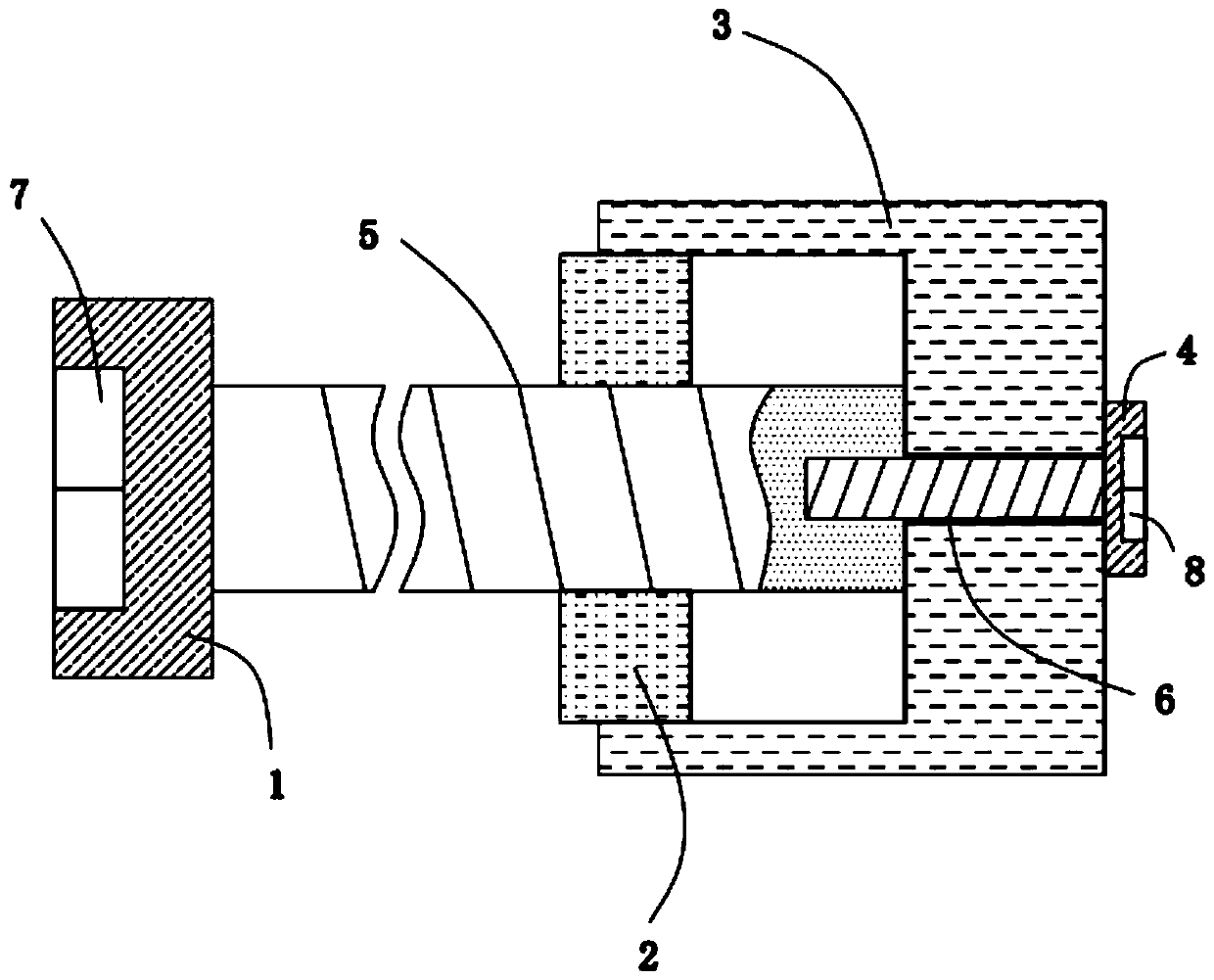

[0037] Based on the anti-loosening screw provided in the first embodiment and the second embodiment of the present application, the third embodiment of the present application proposes another anti-loosening screw. The third embodiment is only a preferred manner of the first embodiment and the second embodiment, and the implementation of the third embodiment will not affect the independent implementation of the first embodiment and the second embodiment.

[0038] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

[0039] Please refer to image 3 The anti-loosening screw rod also includes a first positioning rotation groove 7 provided on the fixed screw rod 1 and a second positioning rotation groove 8 provided on the fixed screw rod 4, the first positioning rotation groove 7 and the second positioning rotation groove 8 The rotating grooves 8 are all regular hexagonal settings.

[0040] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com