Flame stabilizing structure of combustion chamber

A flame stabilization structure and flame stabilization technology are applied in the field of combustion structure device and combustion structure structure, which can solve the problems of difficulty in meeting the requirements of flow resistance and combustion efficiency, so as to enhance flame stability, reduce flow loss, and reduce airflow loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

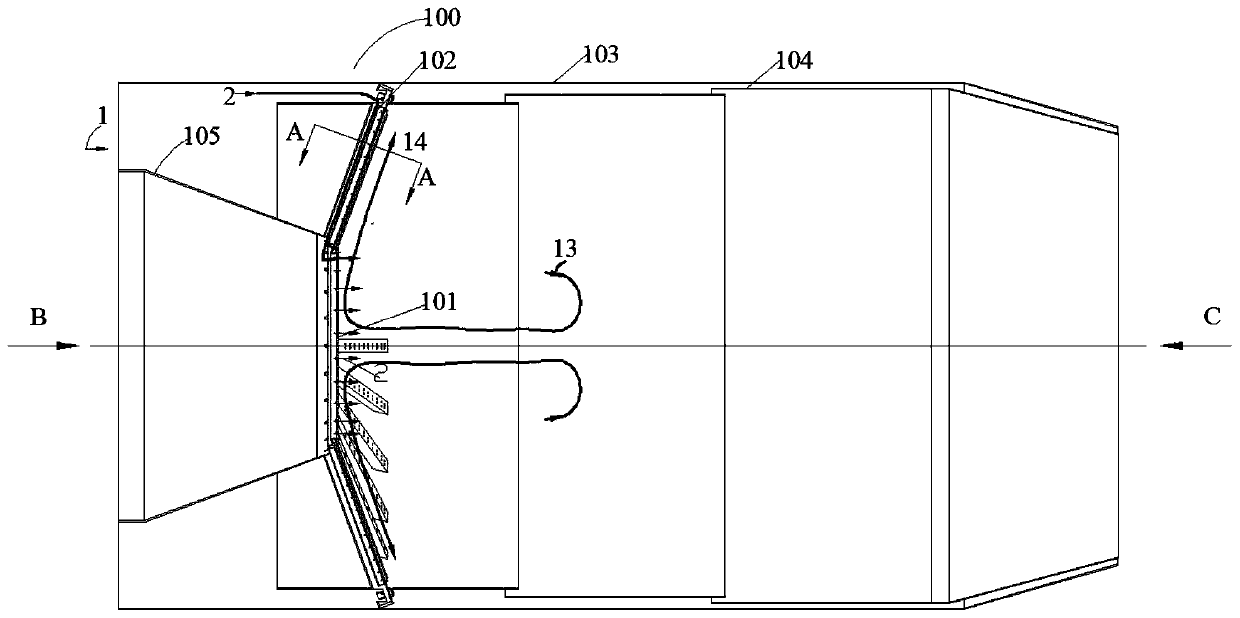

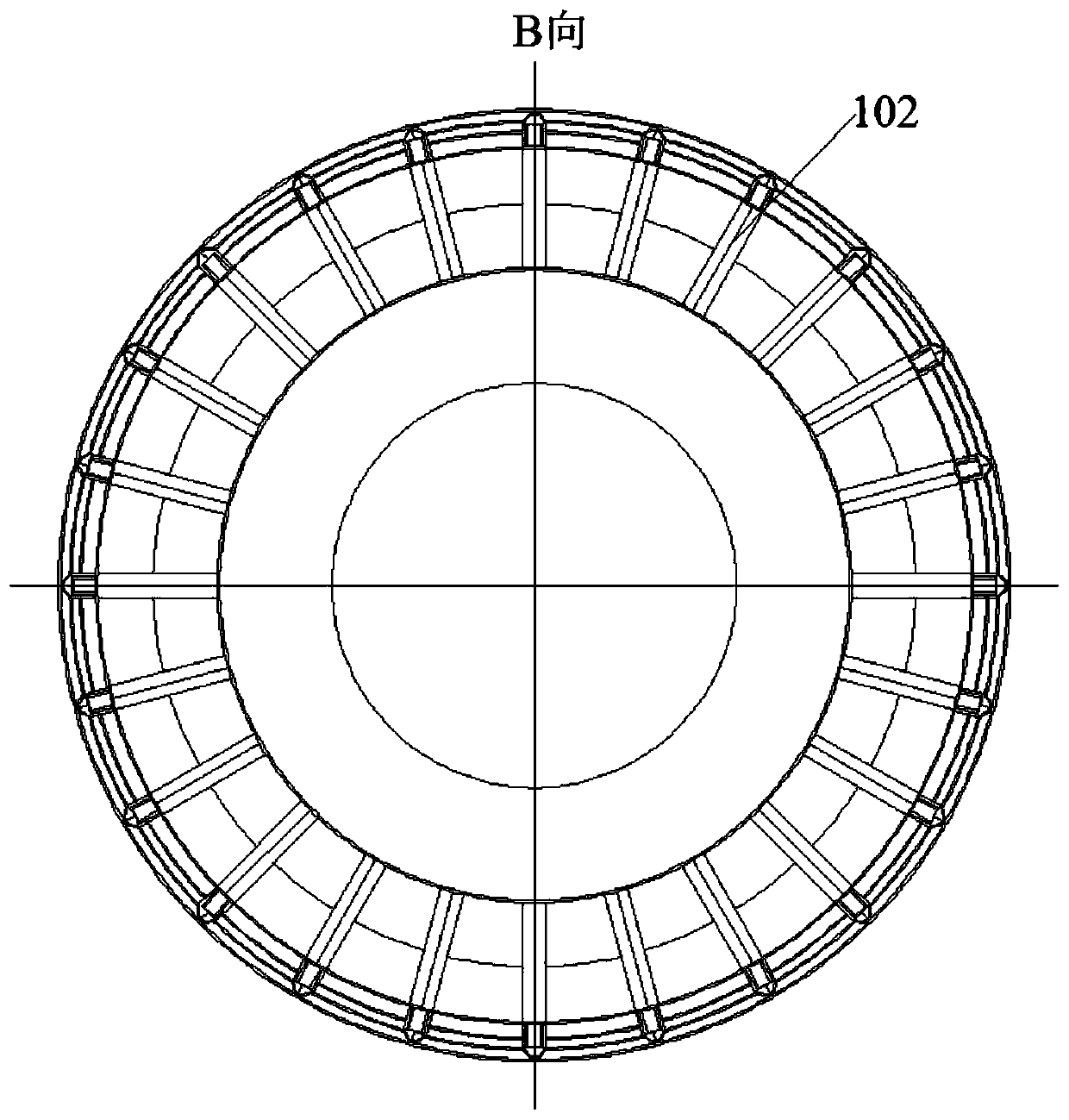

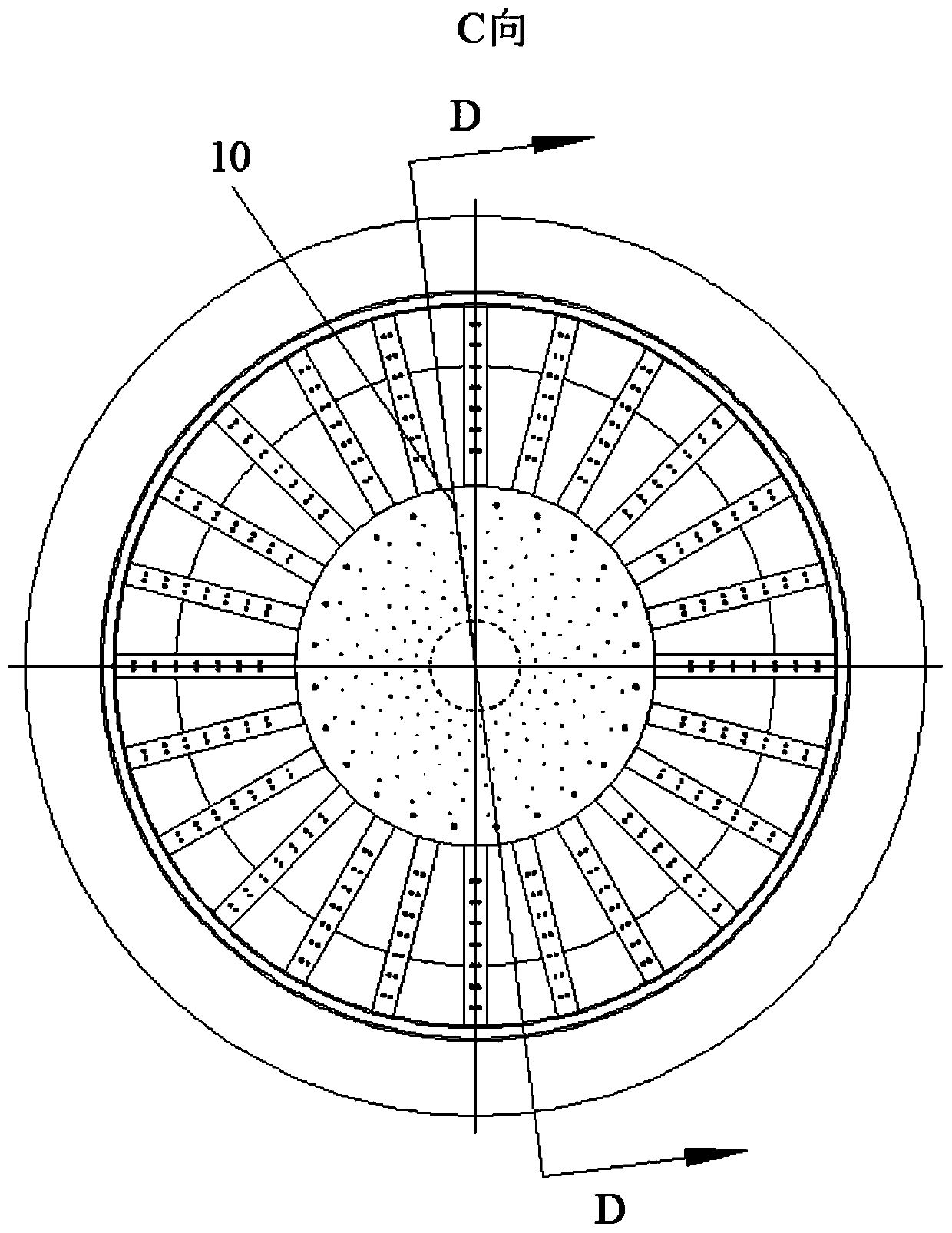

[0029] The combustion chamber flame stabilization structure with enhanced flame stability and reduced losses of the present invention can be widely used in afterburner combustion chambers of turbojet engines with wide speed range and high thrust-to-weight ratio, ramjet combustion chambers or super combustion chambers of turbine-based combined cycle engines. To enhance flame stability and reduce flow loss under high-speed incoming flow conditions. Figure 1~3Shown is the flame stabilization structure of the combustion chamber of the present invention, which is applied to the situation in the afterburner of a turbojet engine with a wide speed range and high thrust-to-weight ratio.

[0030] Such as Figure 1~3 As shown, the afterburner 100 is located behi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com