High-pressure sealing ring testing device and testing method

A high-pressure sealing ring and testing device technology, which is applied in the direction of machine sealing ring testing, fluid tightness testing, and measuring devices, can solve problems such as high cost and product leakage, and achieve simple assembly, guaranteed fidelity performance, and performance evaluation Perfect and comprehensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

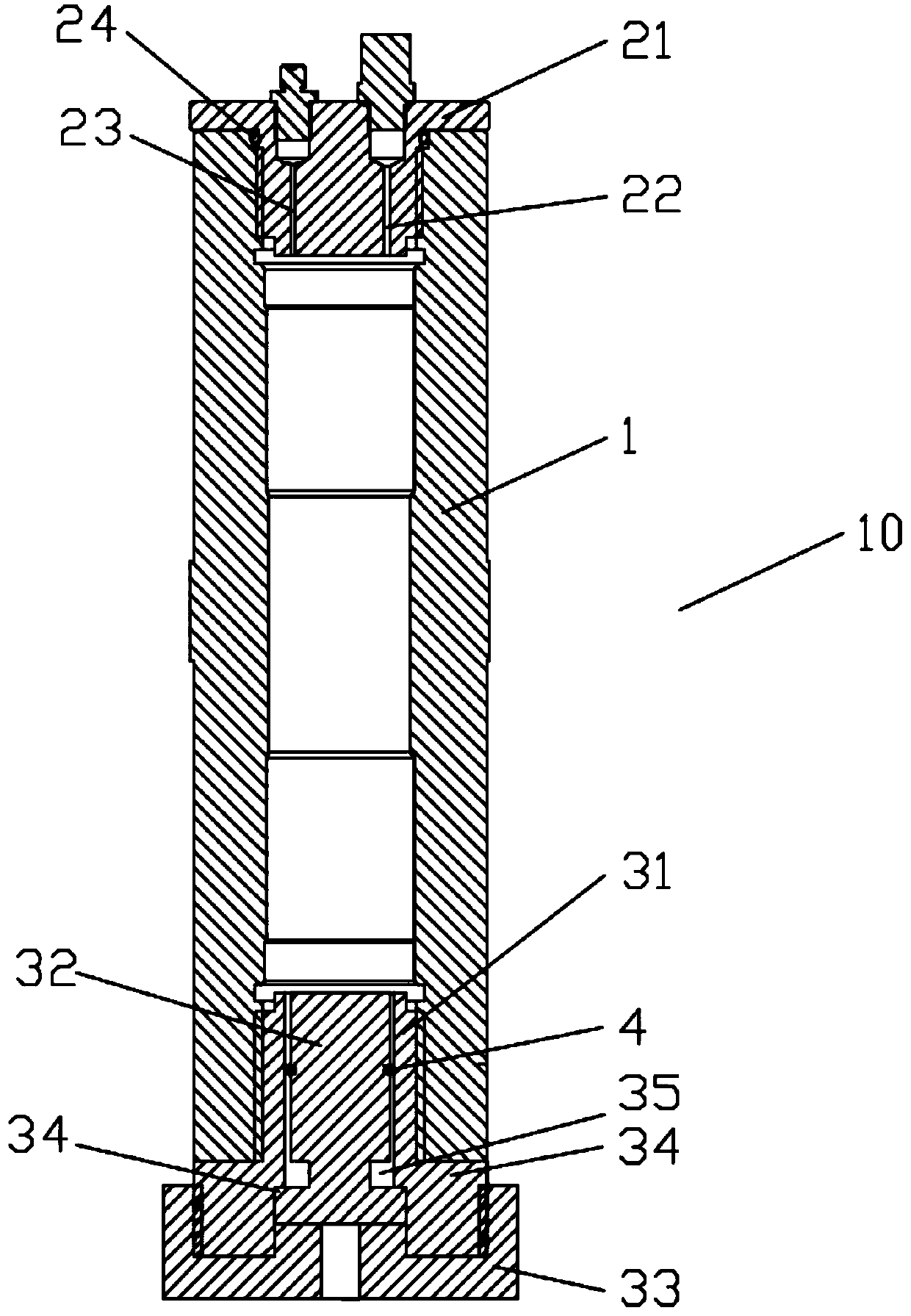

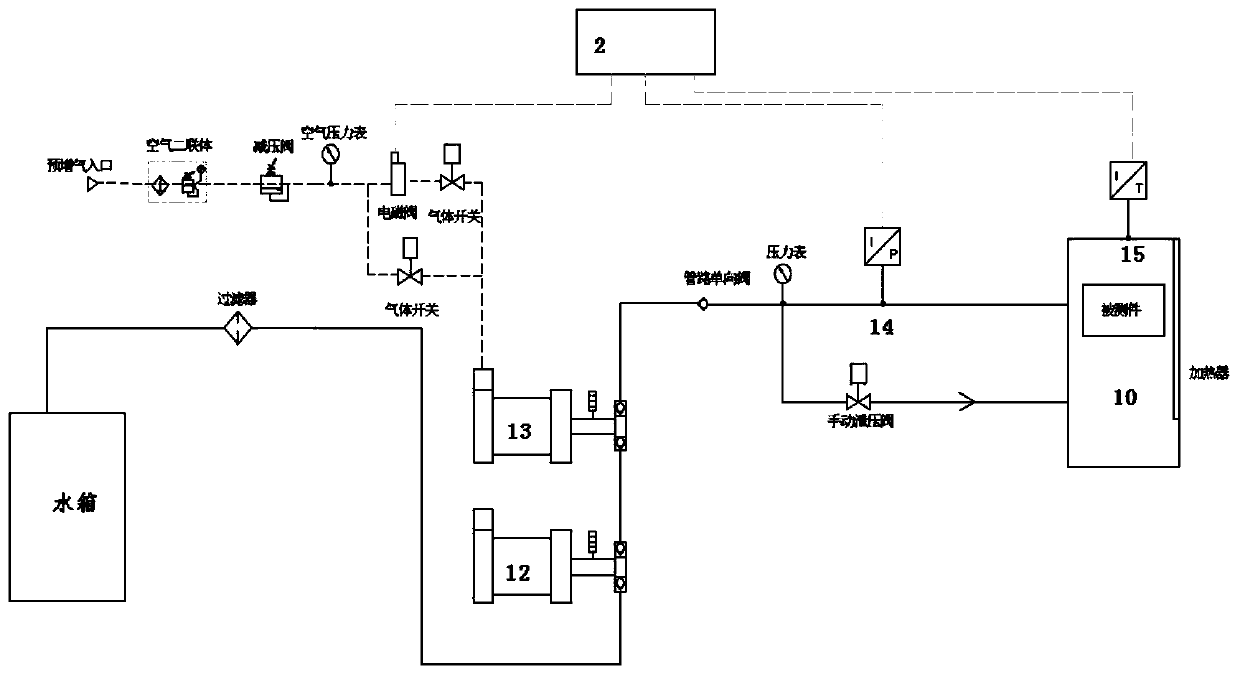

[0029] Such as figure 1 As shown, the high-pressure sealing ring testing device disclosed in the present invention includes a pressure chamber 10, and the pressure chamber 10 includes a cylinder body 1 and a test piece installation structure.

[0030] Both ends of the cylinder body 1 have coaxial threaded holes, and the threaded holes communicate with the interior of the cylinder body 1 . A plug 21 is housed in the threaded hole at one end, and the plug 21 is threadedly connected with the cylindrical body 1 . The plug 21 is provided with a medium channel 22 and a pressure sensor interface 23, the medium channel 22 and the pressure sensor interface 23 axially penetrate the plug 21, and the medium channel 22 serves as an injection port to connect with a hydraulic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com