Outer lead wire device for fixedly assembling electric power instrument box

A power meter and lead wire technology is applied in the field of fixed and assembled external lead wiring devices for power meter boxes, and can solve problems such as poor contact, breakage, and crushed housing of inner wires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

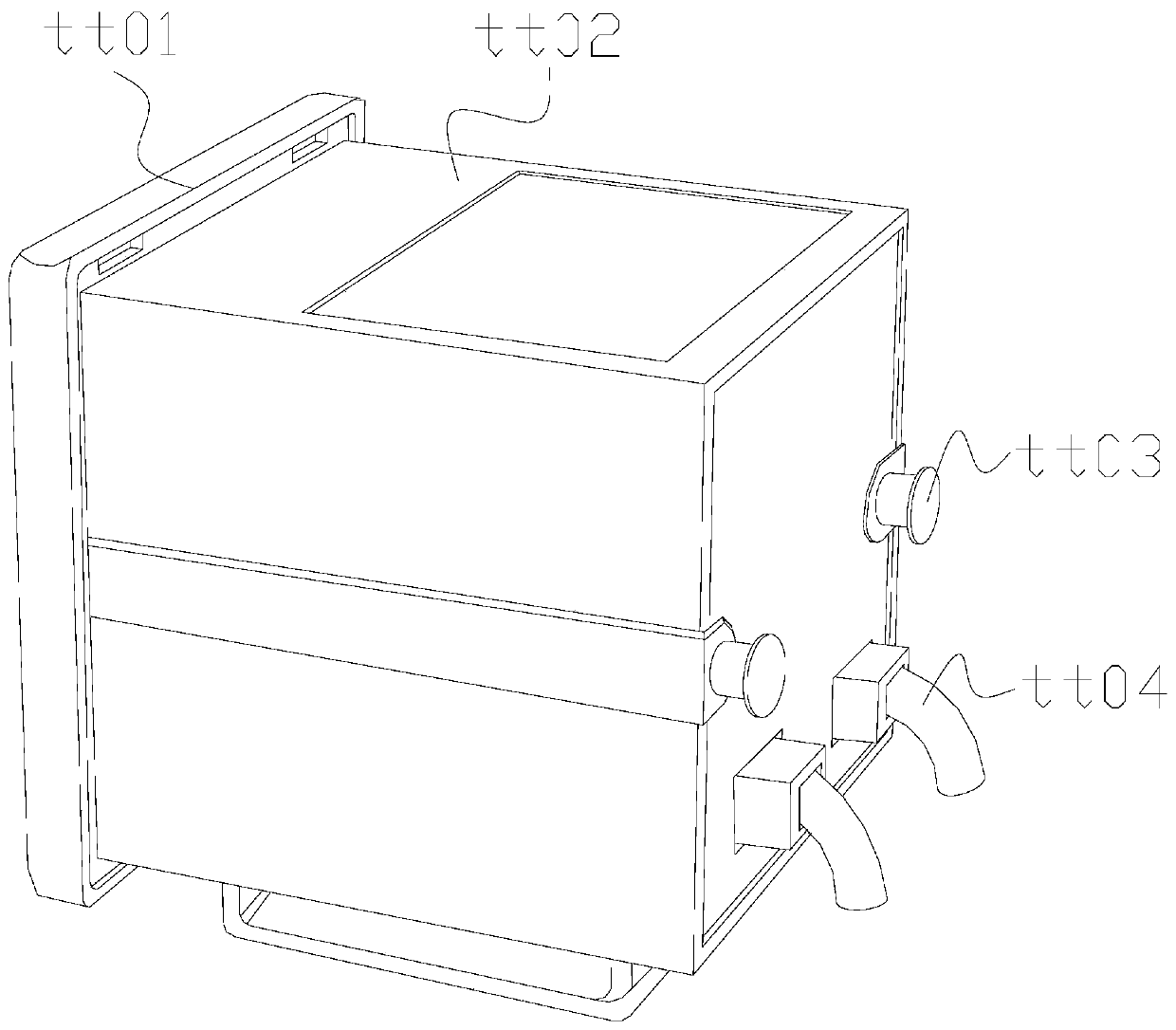

[0030] as attached figure 1 to attach Figure 5 Shown:

[0031] The invention provides a fixedly assembled external lead wiring device for an electric meter box, the structure of which includes a front view surface tt01, an electric meter box tt02, a rear buckle body tt03, and an external lead terminal tt04.

[0032] The front viewing surface tt01 is connected to the electric meter box tt02, and the end of the electric meter box tt02 away from the front viewing surface tt01 is equipped with a rear button tt03, and the external lead terminal tt04 runs through the inside of the electric meter box tt02.

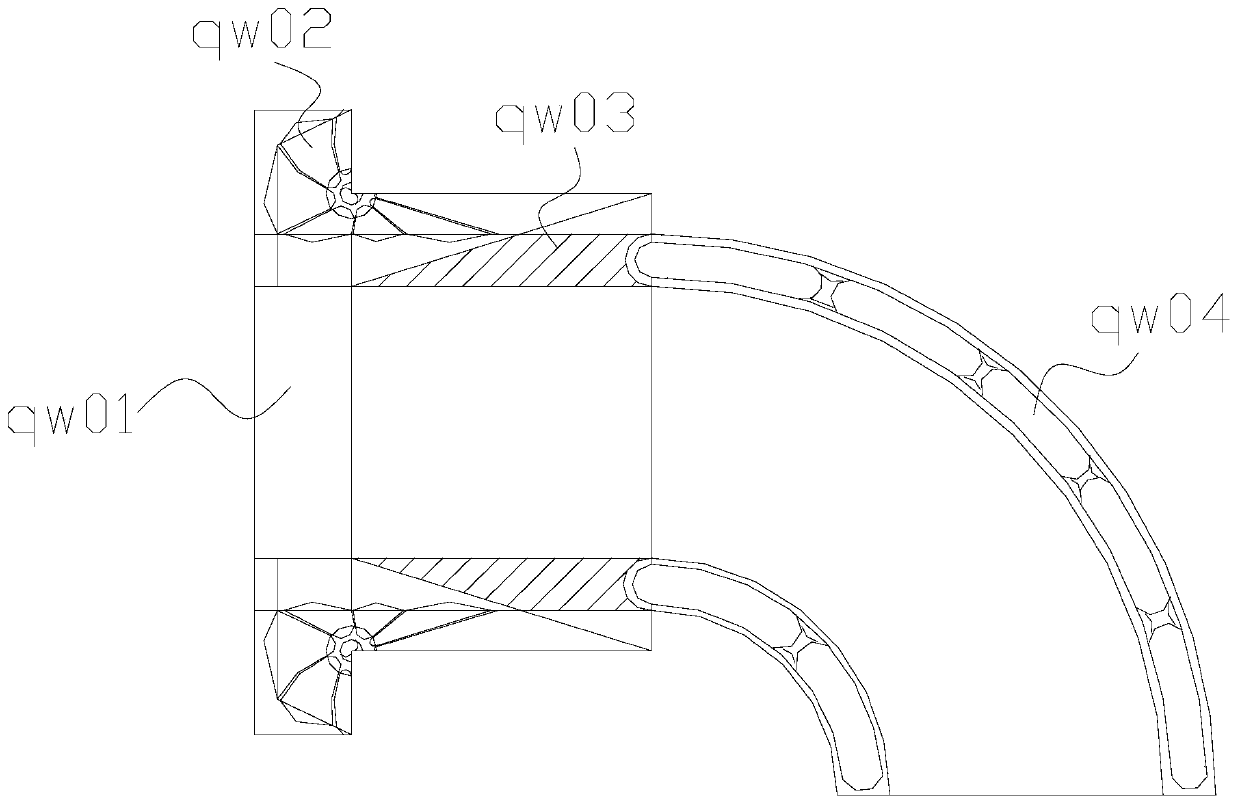

[0033] The external lead terminal tt04 includes an inner wire port qw01, a buckle angle qw02, a pocket shell qw03, and an arc interlayer qw04. The inner wire port qw01 is installed inside the pocket shell qw03, and the pocket shell qw03 is connected with the buckle angle qw02. The arc interlayer qw04 is installed on the outer surface of the pocket shell qw03.

[0034] Wherein...

Embodiment 2

[0040] as attached Figure 6 to attach Figure 7 Shown:

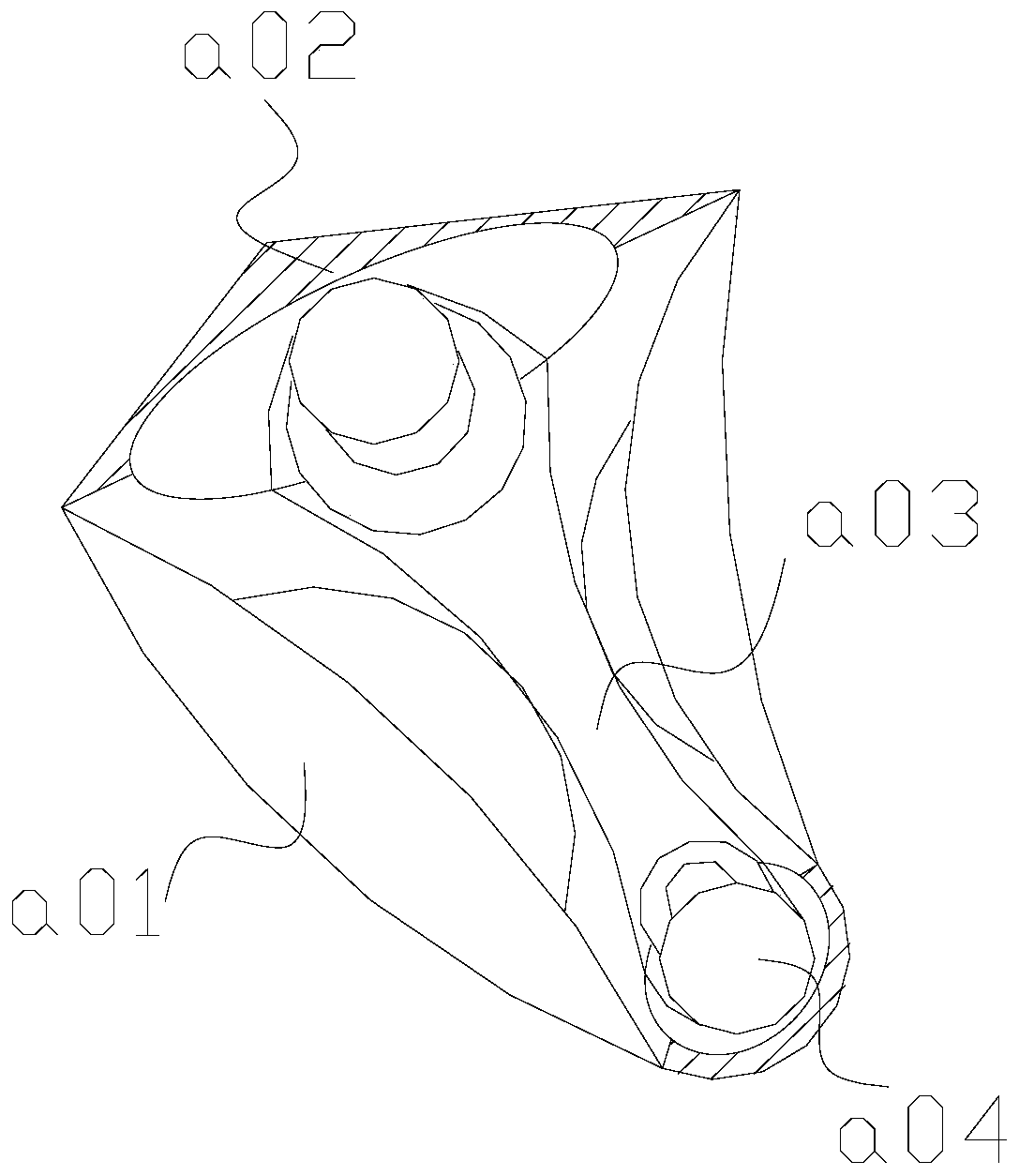

[0041]Wherein, the arc interlayer qw04 includes a nodal ball g01, a rubber holder spread edge g02, an open arc g03, and a spread core g04, the joint ball g01 is connected with the glue support spread edge g02, and the open arc g03 is attached to the spread core On the outer surface of g04, the nodal ball g01 has a spherical structure and four are provided. The spreading core g04 is in an arc-shaped structure. The nodal ball g01 evenly distributes the force received. Bending changes are produced, and the opening arc g03 gives a certain extension angle to the connecting parts.

[0042] Wherein, the rubber bracket spread side g02 includes a pull-back strip www1, a top-fixing ball www2, an expanding body www3, and a ball-holding body www4. The ball-holding body www4 and the pull-back strip www1 are an integrated structure. Installed on the outer surface of the expander www3, the retaining sphere www4 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com