Carton recycling equipment

A technology for recycling equipment and cartons, which is applied in the direction of cleaning hollow objects, presses, grain processing, etc., and can solve problems such as occupation, manual operation, and large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

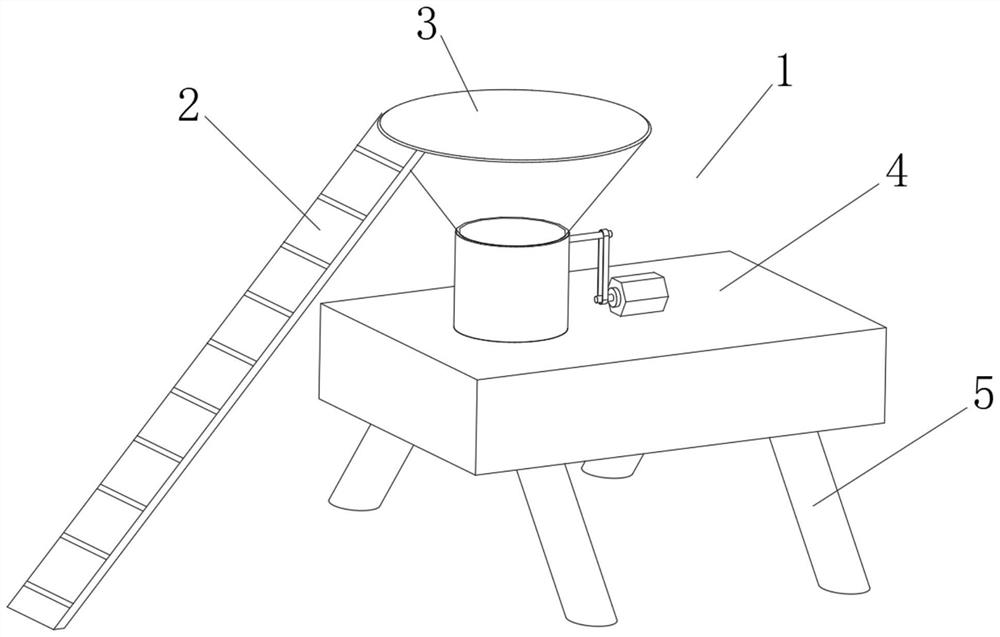

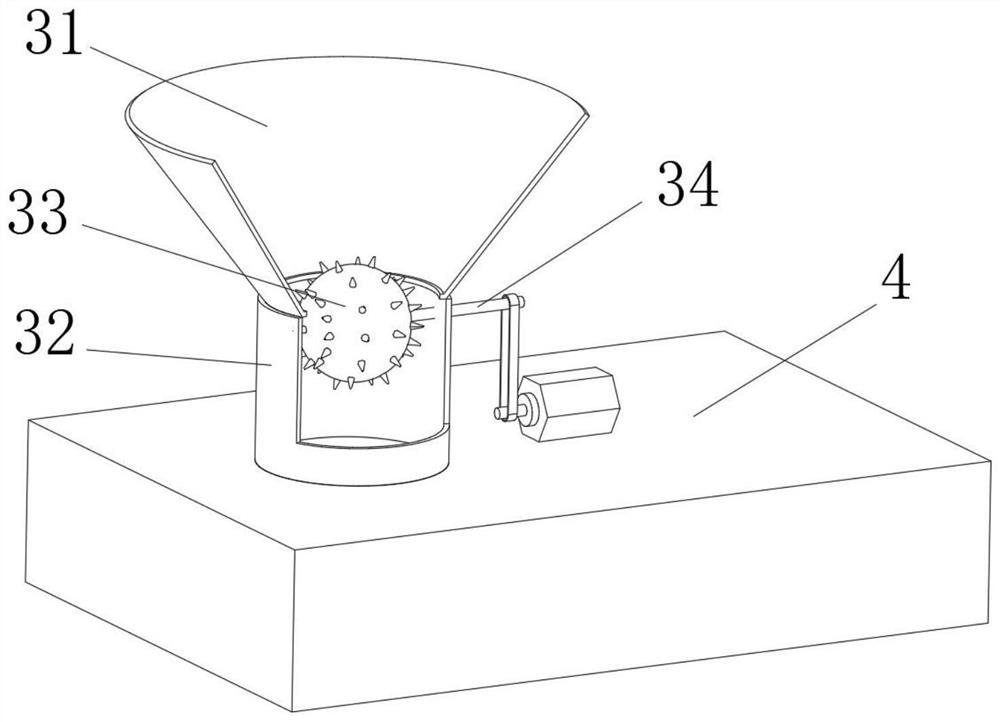

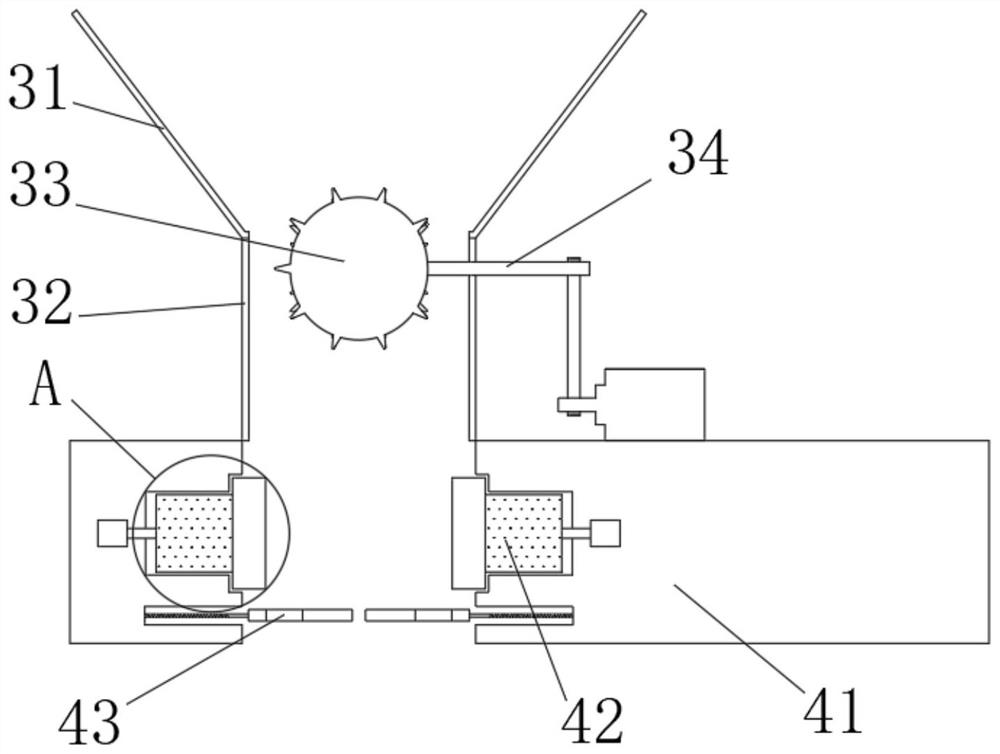

[0042] see Figure 1-4 , the present invention provides a technical solution: a recycling device for cartons, comprising a carton recycling device body 1 composed of a conveyor belt 2, a feeding mechanism 3, an extrusion mechanism 4 and a base 5, the right side of the conveyor belt 2 and the feeding The top of the feeding mechanism 3 is fixedly connected, the bottom of the feeding mechanism 3 communicates with the top of the extruding mechanism 4, the bottom of the extruding mechanism 4 is fixedly connected with the top of the base 5, and the feeding mechanism 3 includes a feeding frame 31. The bottom of frame 31 is fixedly connected with feed pipe 32, and the inside of feed pipe 32 is provided with coiling material mechanism 33, and the inside of coiling material mechanism 33 is fixedly connected with transmission rod 34, and the left end of transmission rod 34 and the inside of feed pipe 32 Rotationally connected, the right end of the transmission rod 34 is rotationally conn...

Embodiment 2

[0048] see Figure 1-5 , on the basis of Embodiment 1, the present invention provides a technical solution: the coiling mechanism 33 includes a solid block 331, the inside of the solid block 331 is fixedly connected to the outside of the transmission rod 34, and the outside of the solid block 331 is fixedly connected There is a magnetic block 332, and the side of the magnetic block 332 away from the middle solid block 331 is fixedly connected with a magnetic bar 333, and the side of the magnetic bar 333 away from the magnetic block 332 is fixedly connected with a blowing mechanism 334 through a receiving rod.

[0049] The blowing mechanism 334 is fixedly connected with a coiled material spheroid 335 on one side away from the magnetic bar 333, and the outer side of the coiled material spheroid 335 is fixedly connected with a coiled material block 336, and the inside of the coiled material spheroid 335 is provided with an air blow hole 337, and the solid block 331 The outer side...

Embodiment 3

[0053] see Figure 1-7 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the coil block 336 includes an outer connection block 3361, the top of the outer connection block 3361 is fixedly connected with a cutting knife 3362, and the outer side of the outer connection block 3361 The friction knife 3363 is rotatably connected through the reset piece, and the bottom of the outer connection block 3361 is slidably connected with the inside of the rolling material sphere 335 through a telescopic mechanism.

[0054] The air blowing hole 337 includes an elastic membrane 3371, the left side of the elastic membrane 3371 is fixedly connected with the inside of the rolling material sphere 335, the right side of the elastic membrane 3371 is provided with a filter screen 3372, and the inner wall of the elastic membrane 3371 is fixedly connected with an elastic rod 3373.

[0055] When in use, when the coiling mechanism 33 rotates, it drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com