Multi-axis equipment control method, computing equipment and storage medium

A technology for equipment control and computing equipment, applied in the field of computing equipment and storage media, can solve problems such as collision, maintenance, modification of programs, difficulty in finding problems, bloated equipment control steps, etc., and achieve the goal of simplifying the control process and improving equipment operation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

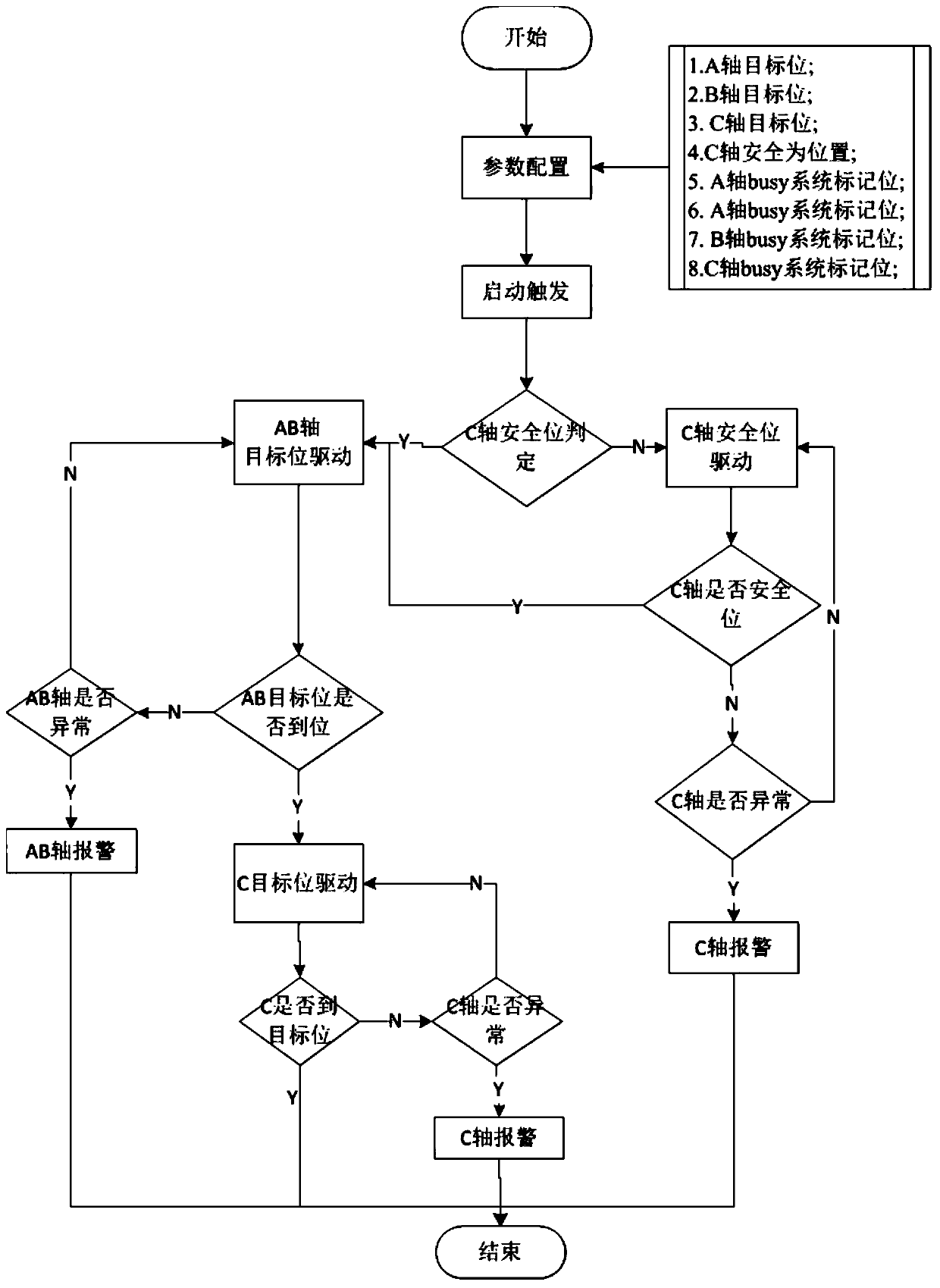

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Note that the aspects described below in conjunction with the drawings and specific embodiments are only exemplary, and should not be construed as limiting the protection scope of the present invention.

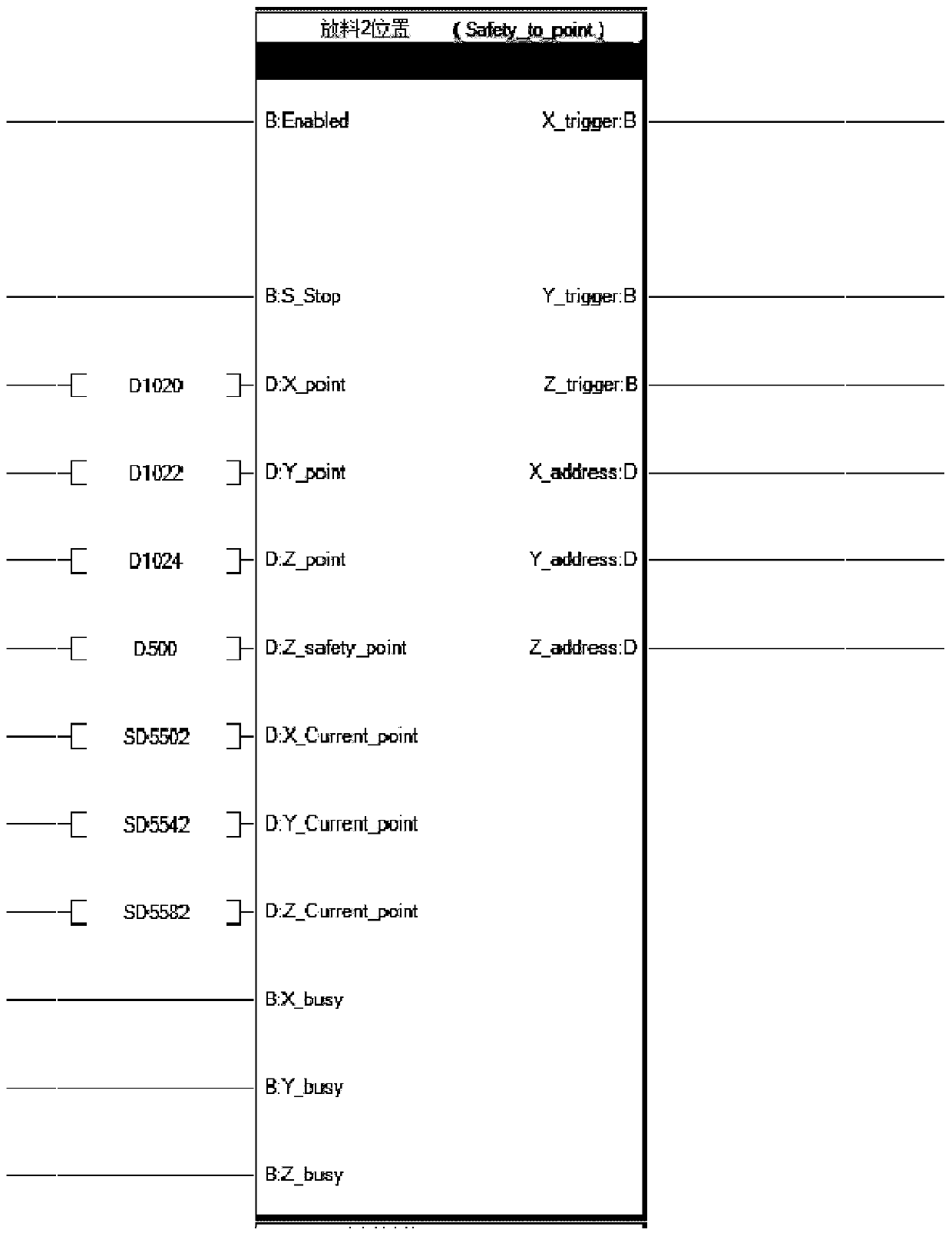

[0020] This device control method can be used for two-axis, three-axis and other multi-axis operation platforms or multi-axis manipulator anti-collision machine control, and can be used through PLC programming languages such as ladder diagram language (LD), instruction list language (IL), function module language ( FBD), sequential function flow chart language (SFC), structured textual language (ST), etc., can also be realized by computer programming language such as C language or assembly language.

[0021] In this embodiment, the device is a three-axis platform, which is controlled by PLC. The platform includes three axes A, B, and C, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com