A bag dust removal device with low air leakage rate for environmental dust removal

A technology of bag dust removal and air leakage rate, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of poor connection between Venturi tube and bag, poor filtration efficiency, high difficulty, etc., and achieve dust removal Easy and fast operation, improved filtration efficiency, and the effect of avoiding dust leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

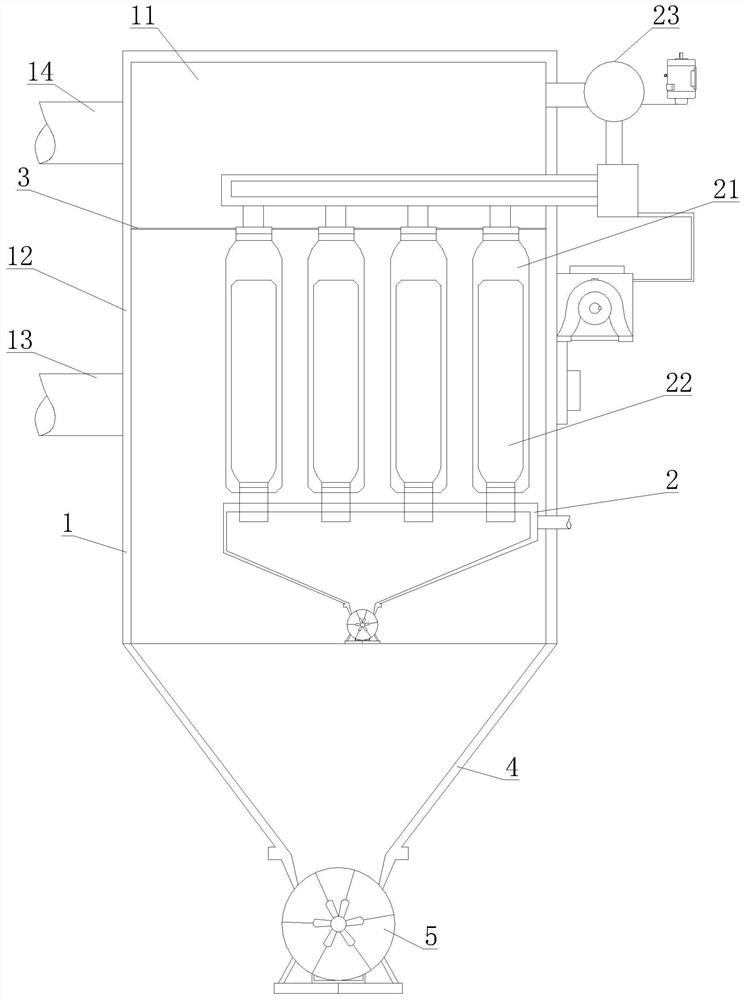

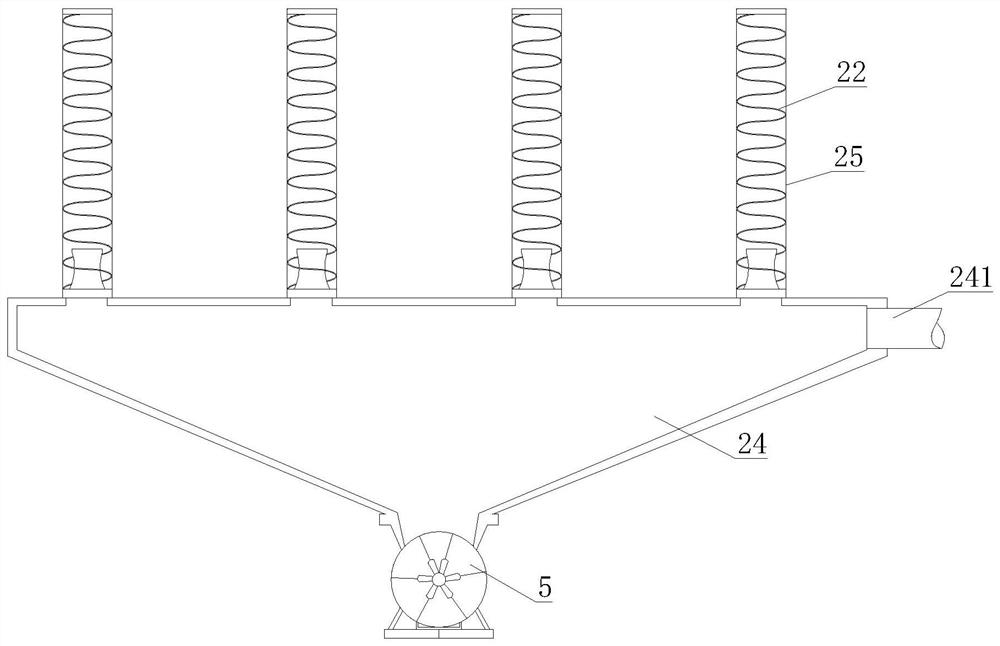

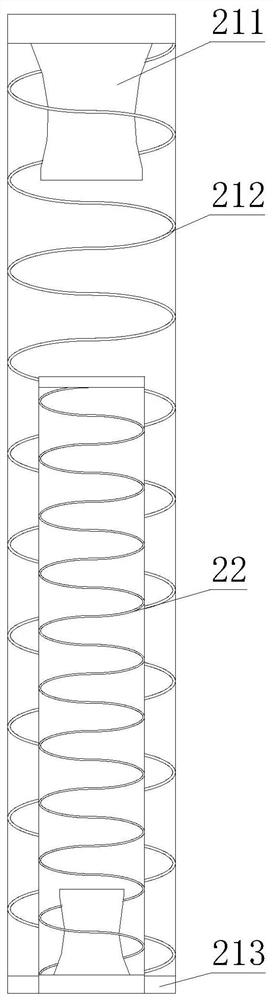

[0026] refer to figure 1 , an environmental dust removal low air leakage rate bag dust removal device, comprising a dust filter tube 1, a bag filter mechanism 2, a partition 3 and a dust collection tube 4, a bag filter mechanism 2 is installed in the middle of the dust filter tube 1, and the lower end of the dust filter tube 1 is provided with The dust collection cylinder 4, the lower end of the dust collection cylinder 4 and the dust inner cylinder 24 are all equipped with a rotary feeding valve 5 for feeding and discharging the settled dust. The middle part of the dust filter cylinder 1 is equipped with a partition 3, which will The inner cavity of the dust filter cartridge 1 is divided into an upper chamber 11 and a lower chamber 12, and the side wall of the dust filter cartridge 1 is provided with a first air inlet 13 and an air outlet 14, the first air inlet 13 communicates with the lower chamber 12, and the outlet The air port 14 communicates with the lower chamber 12, a...

Embodiment 2

[0031] refer tofigure 1 , an environmental dust removal low air leakage rate bag dust removal device, comprising a dust filter tube 1, a bag filter mechanism 2, a partition 3 and a dust collection tube 4, a bag filter mechanism 2 is installed in the middle of the dust filter tube 1, and the lower end of the dust filter tube 1 is provided with The dust collection cylinder 4, the lower end of the dust collection cylinder 4 and the dust inner cylinder 24 are all equipped with a rotary feeding valve 5 for feeding and discharging the settled dust. The middle part of the dust filter cylinder 1 is equipped with a partition 3, which will The inner cavity of the dust filter cartridge 1 is divided into an upper chamber 11 and a lower chamber 12, and the side wall of the dust filter cartridge 1 is provided with a first air inlet 13 and an air outlet 14, the first air inlet 13 communicates with the lower chamber 12, and the outlet The air port 14 communicates with the lower chamber 12, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com