Device for removing oil from circulating water

A circulating water and oil filtering technology, applied in the direction of grease/oily substance/floating matter removal device, gravity filter, loose filter material filter, etc., can solve equipment and personnel hazards, increase internal leakage points, equipment aging, etc. problems, to achieve the effect of solving excessive oil content and eliminating major safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

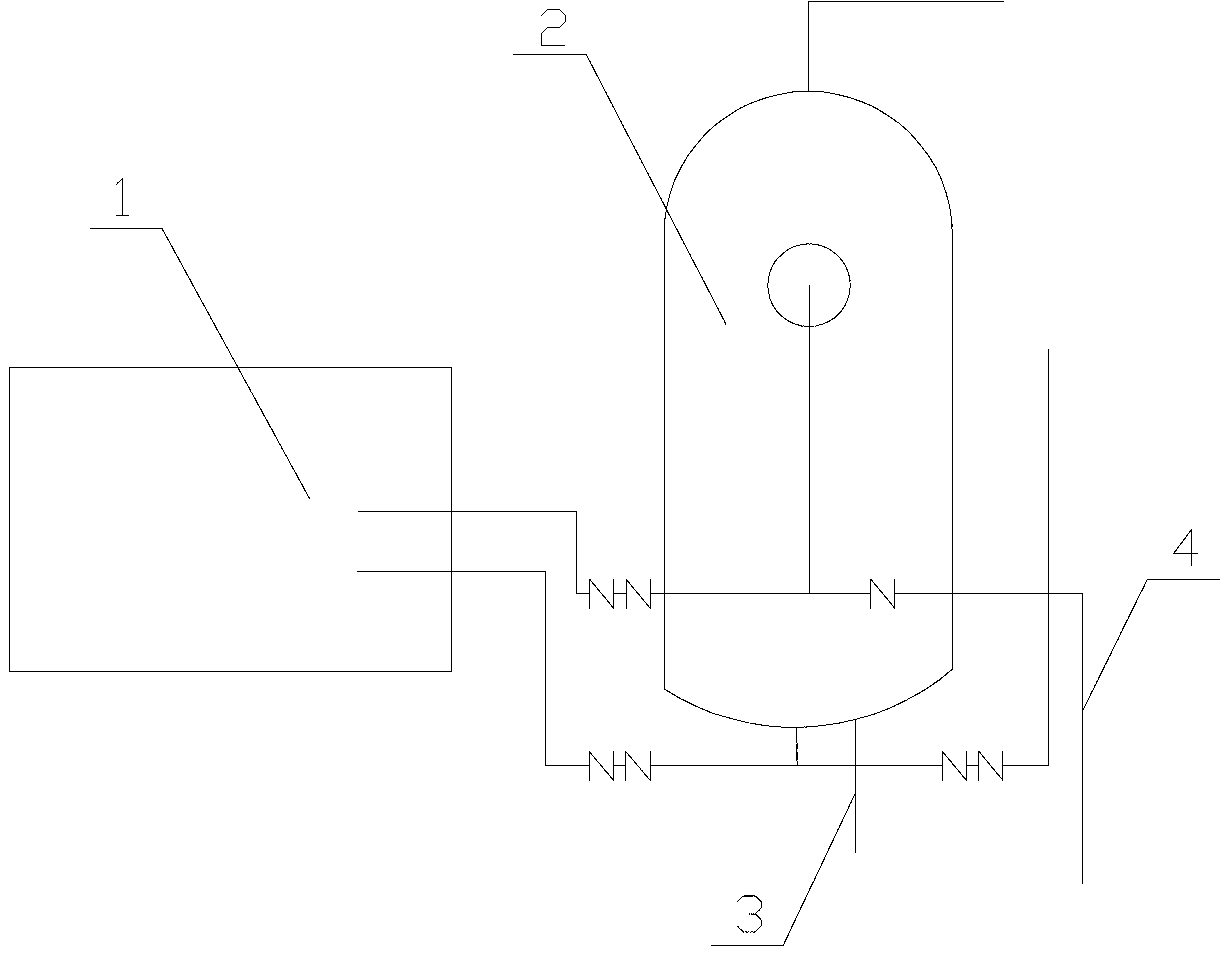

[0010] A kind of circulating water degreasing device provided in this embodiment has a structure such as figure 1 As shown, it includes a fiber bundle filter 2 connected to a sewage tank 1, and fiber ball filler is filled in the fiber bundle filter. Because the existing fiber bundle filter does not have the characteristics of filtering oil, fiber ball packing is installed inside the filter, the circulating water is filtered to remove oil, and the backwash pipeline 3 is used to dilute the sodium carbonate regularly to clean the inside The fibers are degreased and cleaned, and then discharged from the sewage outlet 4 to ensure that they can be recycled. At present, the oil removal effect is relatively obvious, and the oil content in the pool meets the air separation operation standard, eliminating the hidden danger of the air separation unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com