Hoisting and transporting device for aluminum plate coil

A technology of transportation device and aluminum plate, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of production safety accidents, falling and detachment of aluminum coils, and achieve the effect of avoiding production safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

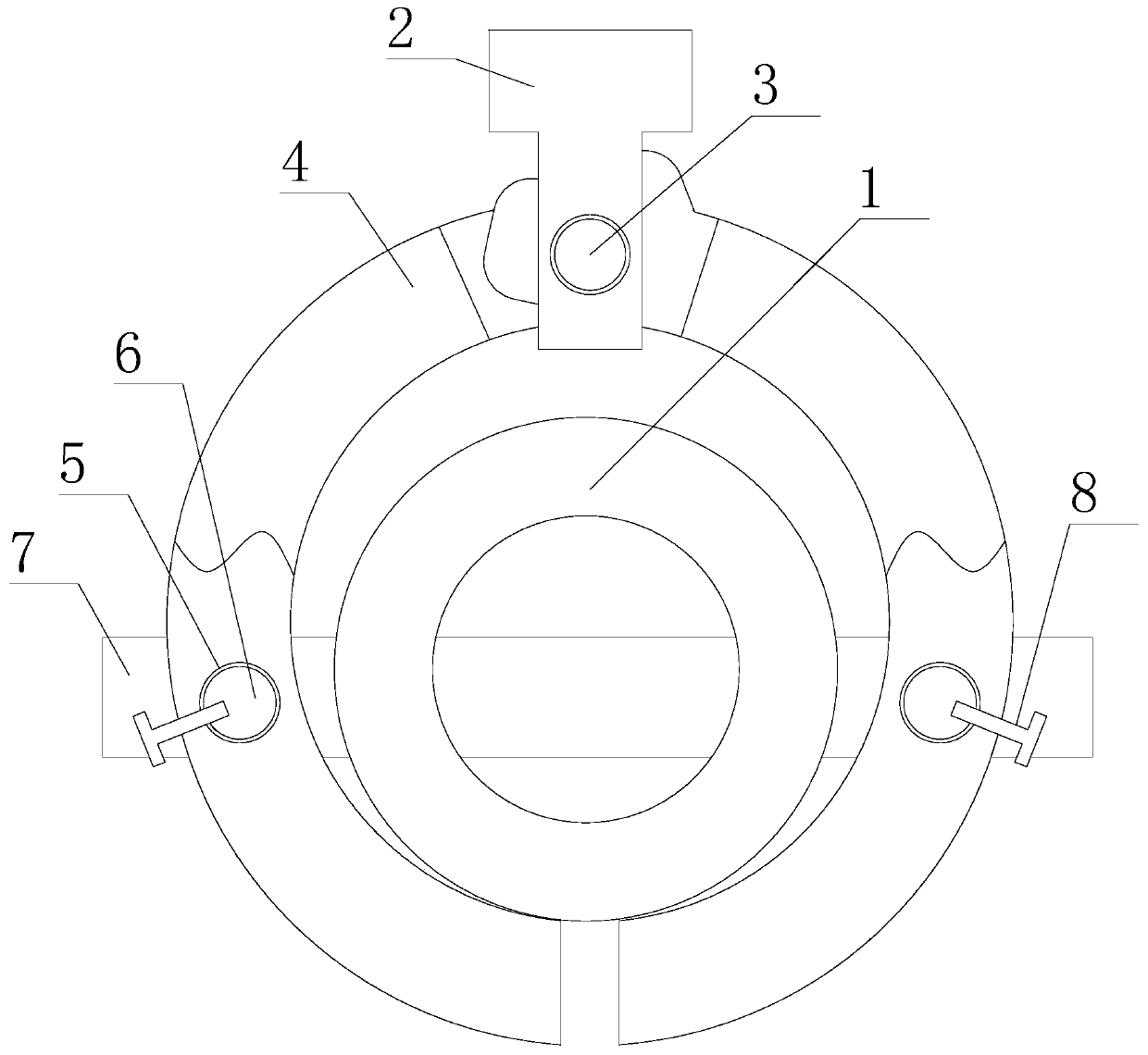

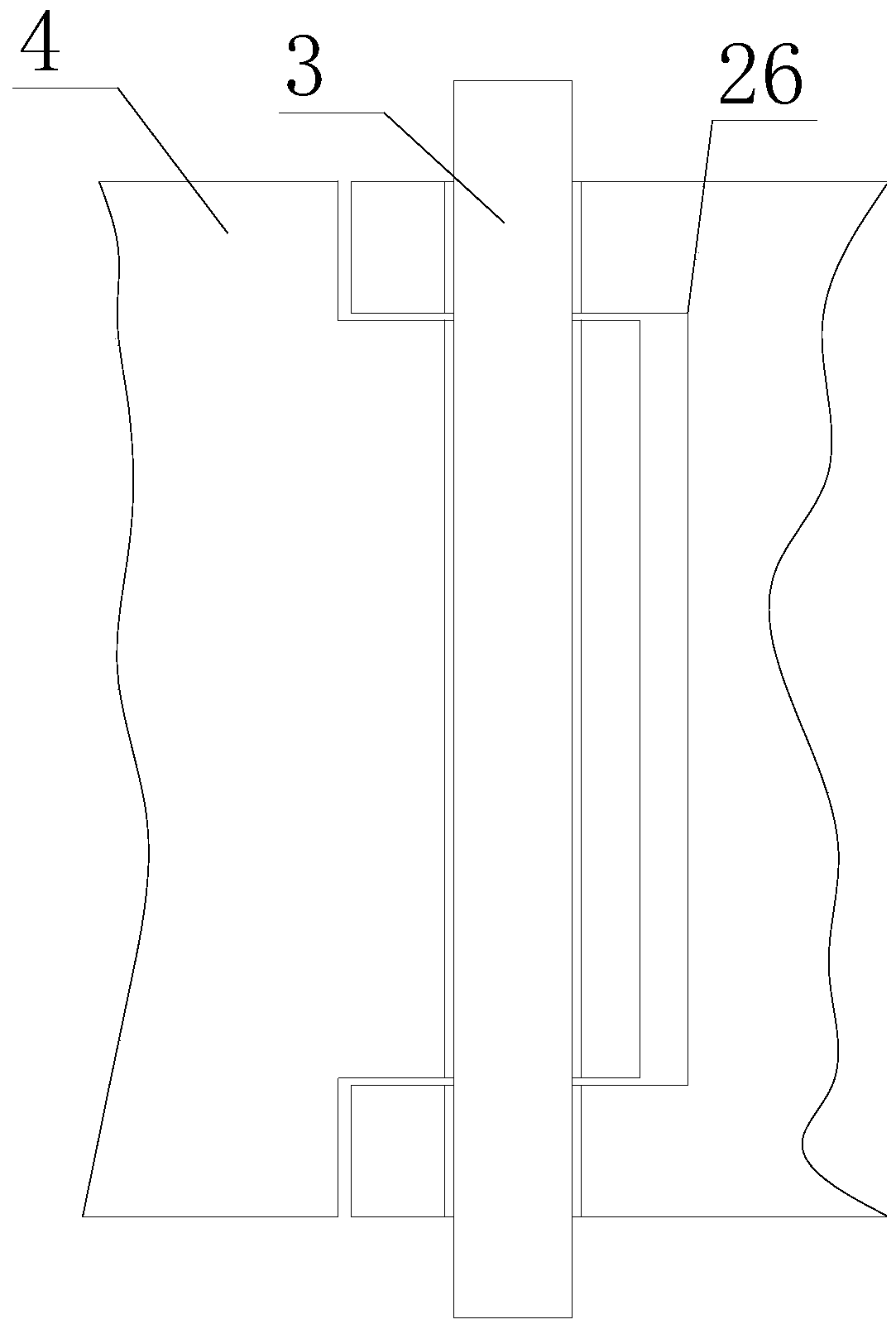

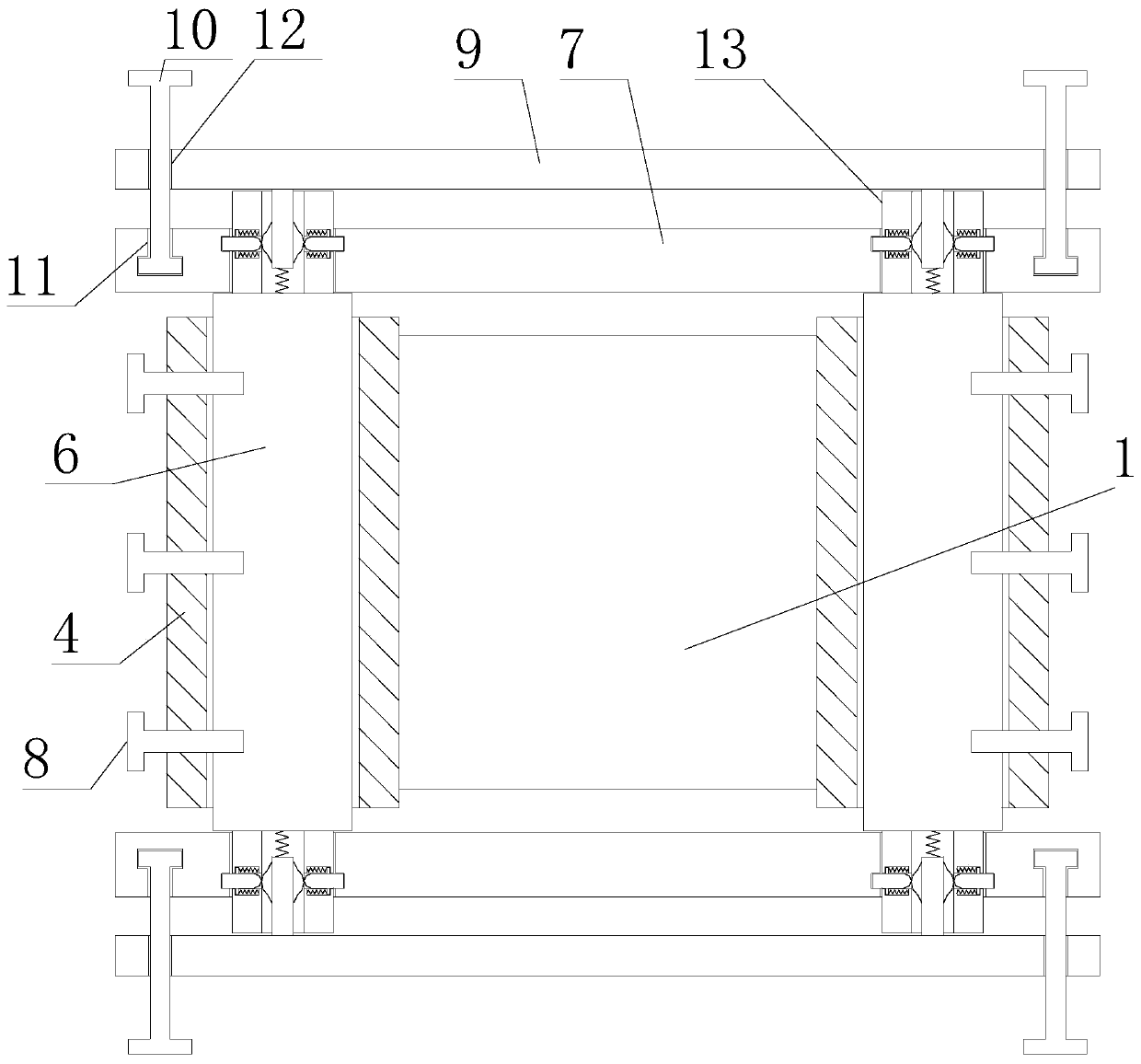

[0041] As an embodiment, the first perforation 5 is located in the lower half of the clamp arm 4, after the aluminum coil 1 is located in the space formed by the inner side of the clamp arm 4, the straight rod 6 is passed through the first perforation 5, and the Both ends of the straight rod 6 are reserved outside the first perforation 5, so that the two ends of the straight rod 6 are fixedly connected with the ends of the straight rod 6 through two limit connection mechanisms, so that the two ends of the aluminum coil are transported There are braces 7 all the time, and when the aluminum coil 1 moves to the brace 7, it plays the role of blocking, ensuring that the aluminum coil 1 will not fall from the two ends of the space formed by the clamp arm 4 inner sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com