Process for preparing polyimides

一种聚酰亚胺、聚酰亚胺前驱的技术,应用在印刷电路制造、用于光机械设备的光敏材料、印刷电路等方向,能够解决低温环化难以实现、聚酰亚胺热性质及机械性质降低等问题,达到降低环化的温度、节省能源及制程成本、缩短环化时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0132] Improved method for preparing polyimide

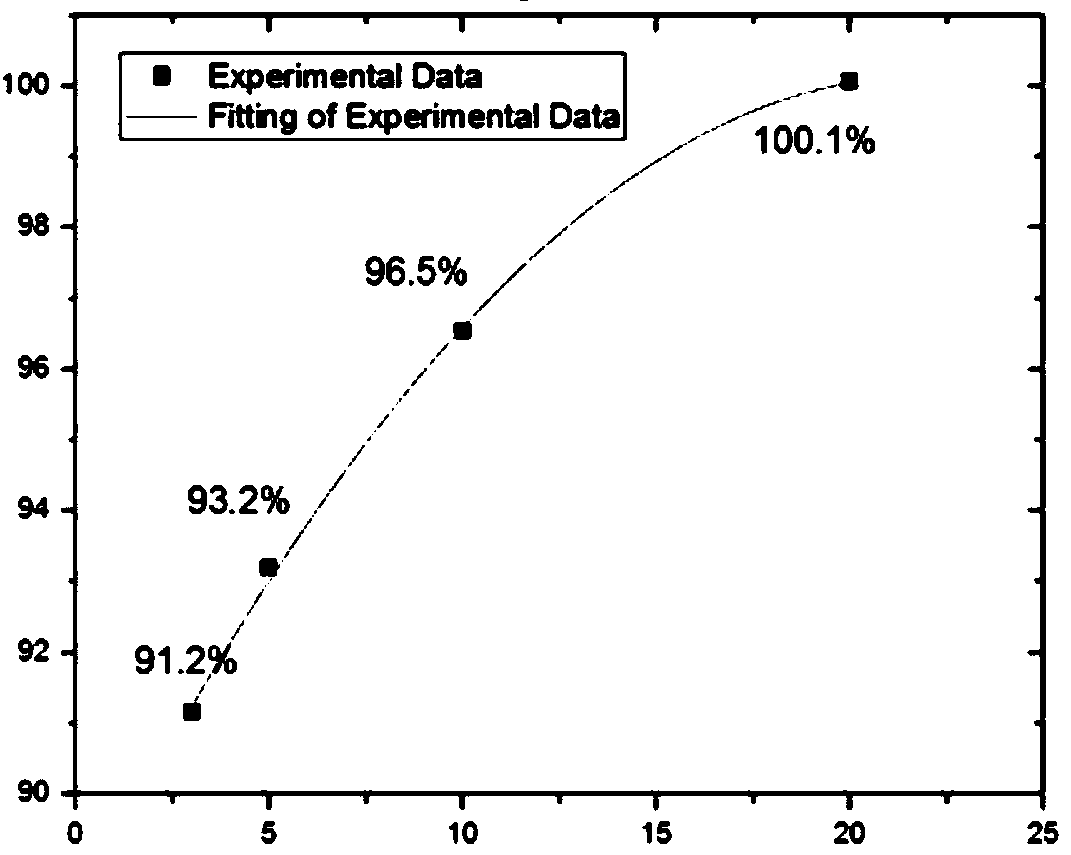

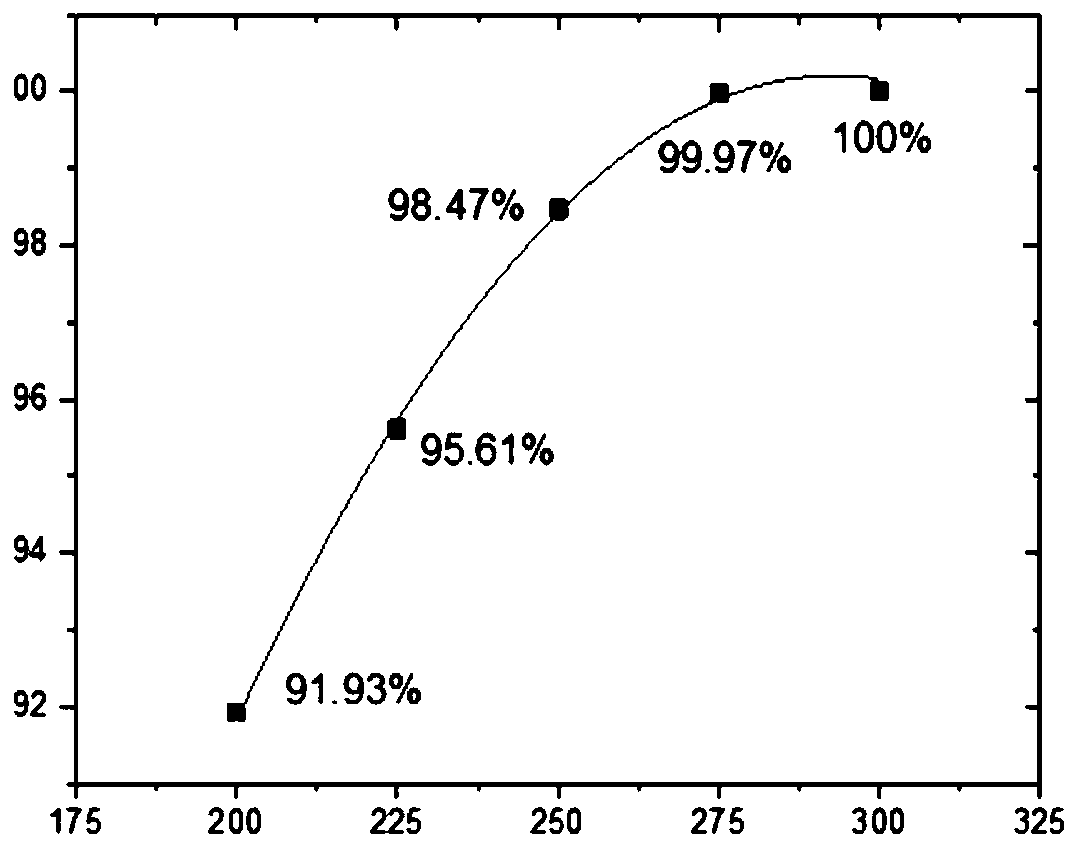

[0133] The present invention provides a method for preparing polyimide, which provides energy to a polyimide precursor composition at low temperature so that the polyimide precursor is efficiently dehydrated and cyclized into polyimide, and can be Removal of solvents, thereby saving energy and process costs.

[0134] The traditional preparation of polyimide is to heat the polyamic acid to convert the polyamic acid into polyimide (imidization, cyclization). Since oxygen and water vapor will cause the molecules of polyamic acid to crack, in order to prevent the material from cracking, it is usually necessary to introduce nitrogen throughout the imidization process, and if the cyclization temperature is lower than 250°C, it will not be able to achieve complete thermal imide 化 (thermalimidization). Therefore, in order to obtain a polyimide polymer with excellent electrical and physical properties, it is often necessary to perform a long...

preparation example 1

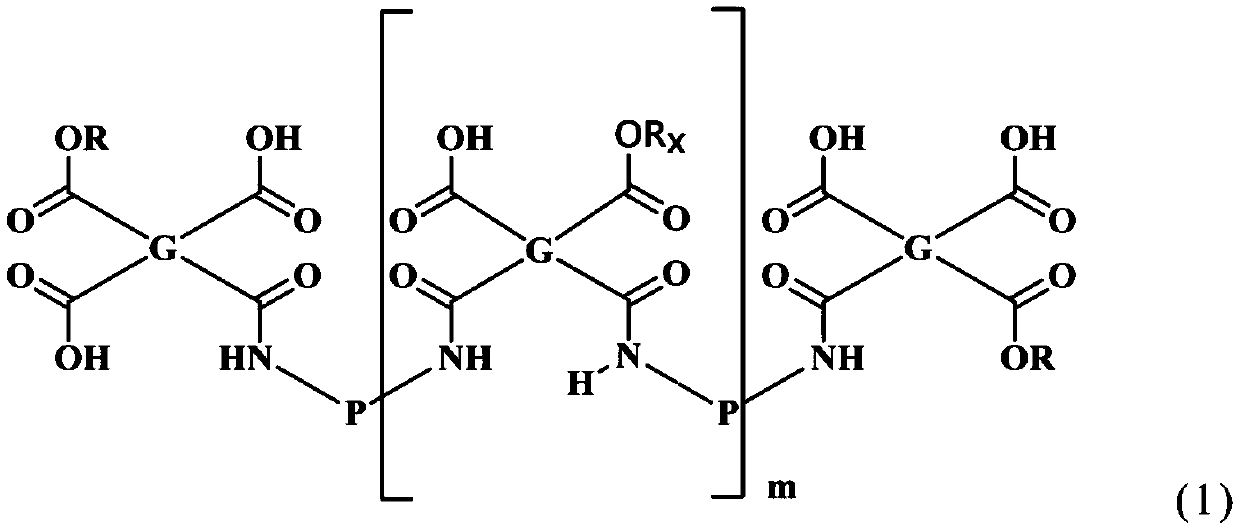

[0167] Preparation Example 1: Preparation of polyimide precursor composition

[0168] 21.81 grams (0.10 mol) of pyromellitic dianhydride (PMDA) was dissolved in 200 grams of N-methyl-2-pyrrolidone (NMP) to obtain a mixture, The mixture was heated to 50°C and the reaction was stirred for two hours. Thereafter, 1.16 g (0.01 mol) of 2-hydroxyethyl acrylate (HEA) was slowly dropped into the mixture, and reacted and stirred at a fixed temperature of 50° C. for two hours. Finally, 20.02 g (0.1 mole) of 4,4'-oxydianiline (4,4'-oxydianiline; ODA for short) was added to the mixture solution, and after it was completely dissolved, it was placed at a fixed temperature of 50°C The reaction was stirred for six hours to obtain a photosensitive polyimide precursor composition with a solid content of about 17 wt%.

preparation example 2

[0169] Preparation Example 2: Preparation of polyimide precursor composition

[0170] 2.181 g (0.01 mol) of PMDA was dissolved in 200 g of NMP and stirred at room temperature for two hours. Slowly drop 1.301 g (0.01 mole) of 2-hydroxyethyl methacrylate (HEMA), heat to 50° C. and stir the reaction for two hours. Then add 10.8140 g (0.1 mol) of p-phenylenediamine (p-PDA) to the solution. After it is completely dissolved, add 19.6308 g (0.09 mol) of PMDA and keep the temperature at 50℃ The reaction was stirred for six hours. Finally, 2.1825 grams (0.01 moles) of di-tert-butyl dicarbonate (Di-tert-butyl dicarbonate; referred to as BOC) was added. 2 O) After stirring for one hour, a photosensitive polyimide precursor composition is obtained with a solid content of about 18% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com