Traffic sign mounting structure

A technology for installation structure and sign boards, applied in the field of sign boards, can solve the problems of slow installation efficiency, actual position error of anchor bolts, bending or tilting of anchor bolts, etc., to improve efficiency, reduce the number of times, and reduce the use of the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

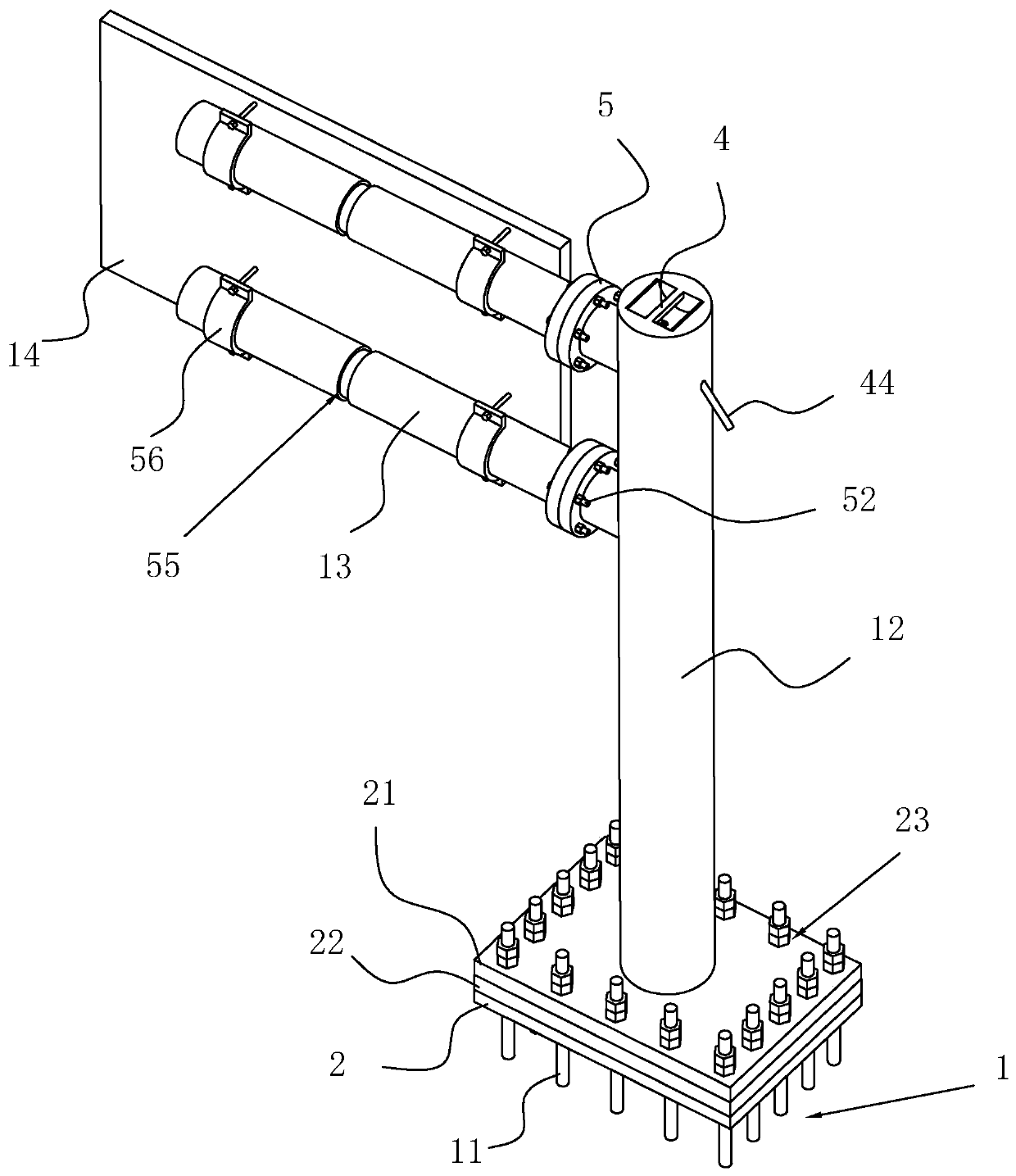

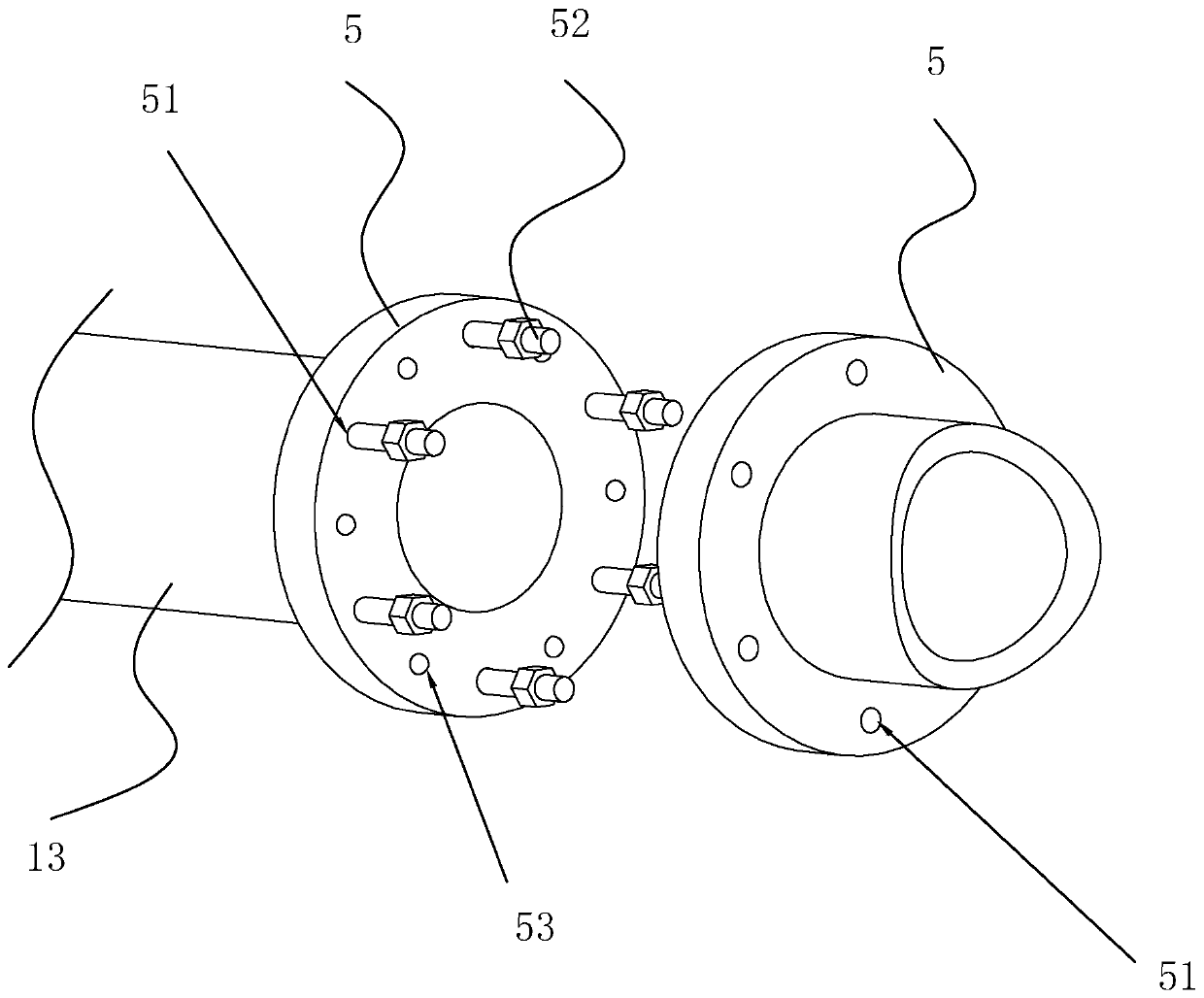

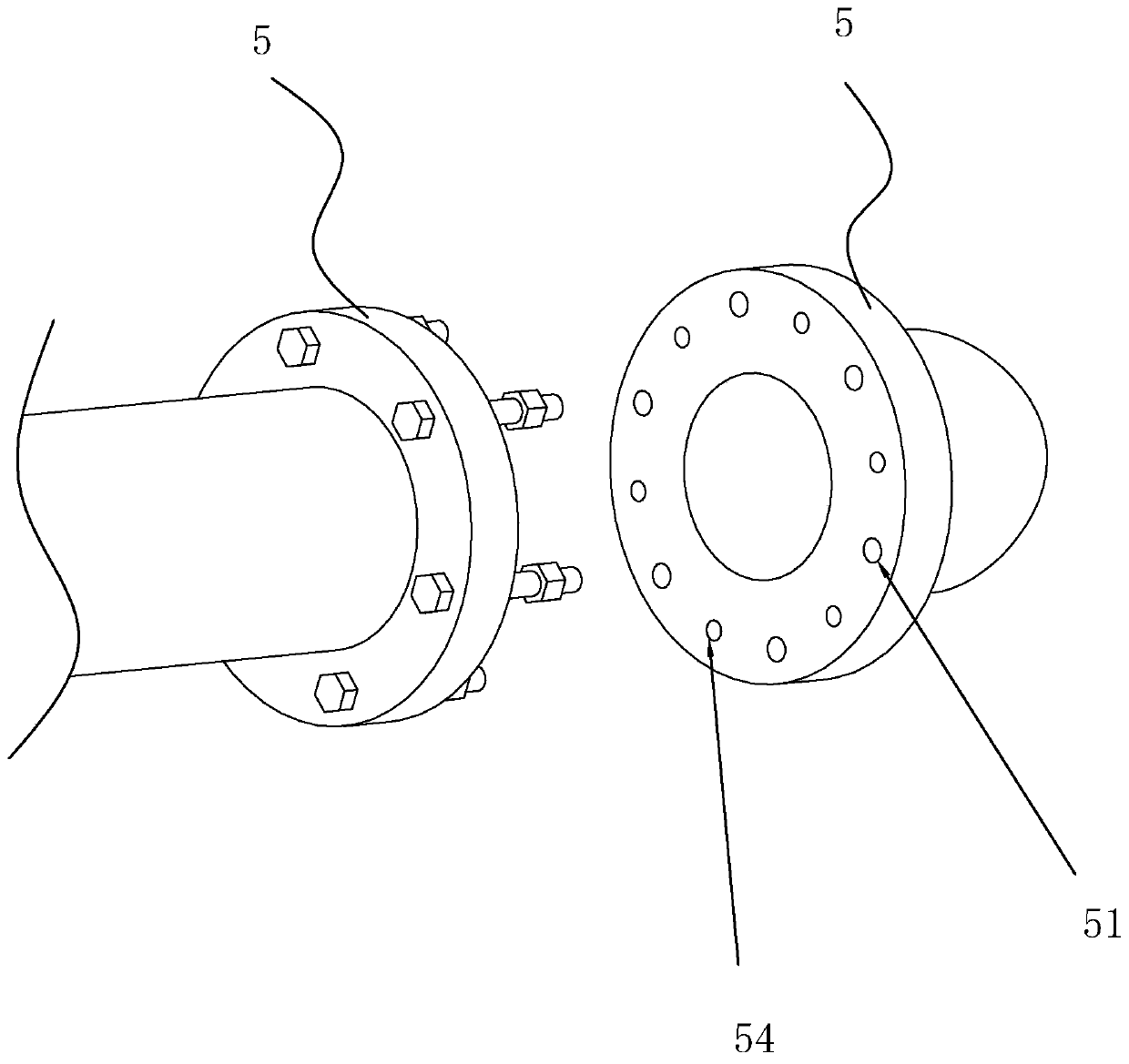

[0034] Such as figure 1 As shown, it is a traffic sign mounting structure disclosed by the present invention, which includes a mounting base 1 that goes deep into the ground and a column 12 installed on the mounting base 1. Embedded plate 2, embedded plate 2 is provided with anchor bolts 11 distributed along the circumferential direction of embedded plate 2, and one end of column 12 is welded with mounting plate 21 made of steel with the upper surface of mounting seat 1 attached and made of steel. There is a first opening 23 for the anchor bolts 11 to pass through, the end of the column 12 away from the mounting plate 21 is provided with a traffic sign 14, and the column 12 is provided with at least two cross bars connecting the traffic sign 14 made of steel 13. The traffic sign 14 is connected to the cross bar 13 by including. In this embodiment, two cross ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com