Steel cable tensioning structure

A steel cable tensioning technology, which is applied in the field of steel cable tensioning structure and tensioning structure, can solve the problems of poor stability of single wheel control, complicated control action, increasing the length of steel cable path, etc., and achieves convenient installation and disassembly, and flexible use Convenience and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

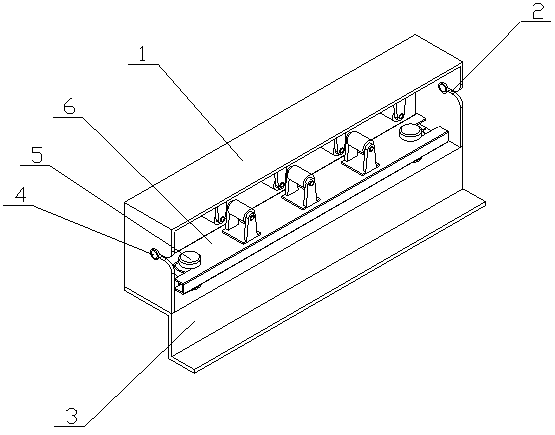

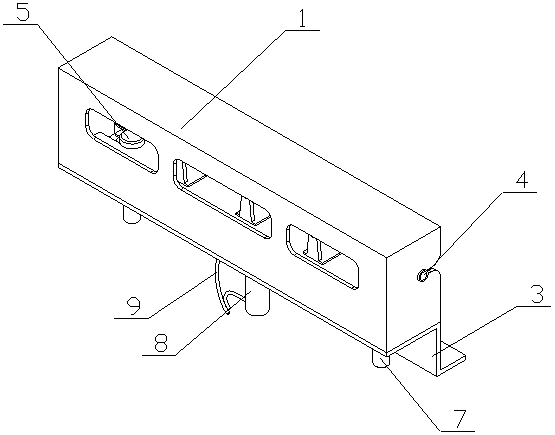

[0016] The steel cable tensioning structure of the present invention is realized in this way: the steel cable tensioning structure of the present invention is composed of a main body device and a tensioning device, and the main body device is composed of an upper box body (1), a side guide groove (2), a lower supporting plate (3 ) and a transverse guide sleeve (4), the upper box (1) is a rectangular box structure, one side and the bottom of the upper box (1) are open, and the lower supporting plate (3) It consists of a horizontal plate and an L-shaped plate, one side of the horizontal plate is vertically connected to one end of the L-shaped plate, the other end of the L-shaped plate is bent away from the horizontal plate, and the horizontal plate is fixed on the upper box The bottom of the body (1), the two ends of the upper box (1) are respectively provided with side guide grooves (2), and one end of the side guide grooves (2) runs through one side of the upper box (1), so Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap